This is the most economical solution of sliding bearings. It is suitable for high load low speed application where impact and dust environment working conditions existed. In addition to the initial lubricating, periodically lubricating is necessary because marginal lubricating condition can result into a short duration of the bearings. It is not recommended to be used under dry condition and a proper lubrication system must be considered when use this kind of bearings.

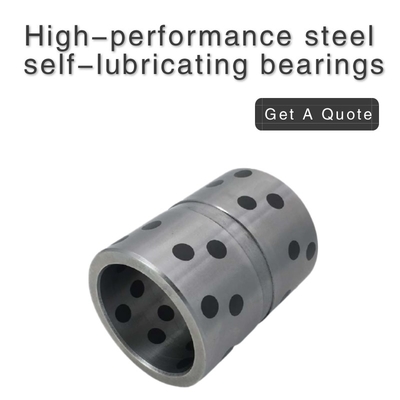

Structure:

Hardened S45C steel bearings. The heat treatment improves the wear resistance and impact resistance of the material. Oil grooves and deposits are available depending on the requirements. The oil grooves and deposits pattern ensure the oil or grease spread evenly on the bearing surface to improve lubricating performance. Combined with self-lubricating technology, the bearing surface could be coated or embedded with solid lubricants to improve its lubricating performance.

Hardened S45C steel, High-performance steel self-lubricating bearings are made of cast iron based metal with special lubricants embedded. The base metal withstands high load and the solid lubricant plugs provide the self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/lower temperature with low speed.

Tech Data

| Max. load | Static | 250N/mm² | Coefficient of thermal expansion | 1.1*10-5 ℃ | ||

| Dynamic | 100N/mm² | Operation Temperature range | -400℃~+120℃ | |||

| Max.speed | Lubricated | 10m/s | Friction coefficient | Lubricated | 0.1~0.25 | |

| Max. PV | Lubricated | 1.5N/mm²*m/s | Alloy Bonding Strength | Roughness | Ra<0.8 | |

| Density | 7.8g/mm³ | Hardness | HRC 58-62 | |||

| Hardness | HB ≥40 | Grease lubricating recommended for every 8 hours | ||||

Typical Applications

The typical applications of this material include the port machinery, forest machinery, construction engineering machinery, truck axles and material handling machinery as well as the rod eyes of the hydraulic cylinders and connecting bearings.

| Unit: mm | ||||||||||||||

| d | D8 | D | S7 | L 0/-0.5 | ||||||||||

| 20 | 25 | 30 | 35 | 40 | 50 | 60 | 70 | 80 | 100 | 120 | ||||

| 30 | +0.098 +0.065 |

38 | +0.068 +0.043 |

■ | ■ | ■ | ■ | ■ | ■ | |||||

| 30 | 40 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 32 | +0.119 +0.080 |

42 | ■ | ■ | ■ | |||||||||

| 35 | 45 | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ||||||

| 38 | 48 | ■ | ■ | ■ | ||||||||||

| 40 | 50 | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | |||||

| 40 | 55 | 0.083 0.053 |

■ | ■ | ■ | ■ | ■ | ■ | ||||||

| 45 | 60 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 50 | 60 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 50 | 62 | ■ | ■ | ■ | ■ | ■ | ||||||||

| 50 | 65 | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ||||||

| 55 | +0.146 +0.100 |

70 | 0.089 0.059 |

■ | ■ | ■ | ■ | ■ | ■ | |||||

| 60 | 75 | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | |||||

| 65 | 80 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 70 | 85 | +0.106 +0.071 |

■ | ■ | ■ | ■ | ■ | ■ | ■ | ■ | ||||

| 75 | 90 | ■ | ■ | ■ | ■ | ■ | ||||||||

| 75 | 95 | ■ | ■ | ■ | ■ | |||||||||

| 80 | 95 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 80 | 100 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 85 | +0.174 +0.120 |

100 | ■ | ■ | ||||||||||

| 90 | 110 | +0.114 +0.079 |

■ | ■ | ■ | ■ | ■ | |||||||

| 100 | 120 | ■ | ■ | ■ | ■ | ■ | ■ | |||||||

| 110 | 130 | +0.132 +0.092 |

■ | ■ | ■ | ■ | ■ | ■ | ||||||

| 120 | 140 | ■ | ■ | ■ | ■ | |||||||||

| 130 | +0.208 +0.145 |

150 | +0.140 +0.100 |

■ | ■ | ■ | ||||||||

| 140 | 160 | ■ | ■ | |||||||||||

| 150 | 170 | +0.148 +0.108 |

■ | ■ | ■ | |||||||||