|

|

| Brand Name: | VIIPLUS |

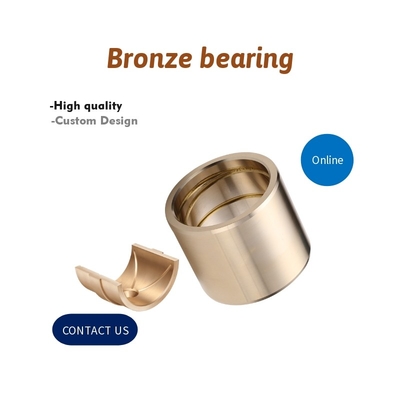

| Model Number: | Bronze bearing |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 7000000 Piece/Pieces One week |

Solid Self-Lubricating Bronze Sleeve Bushings are precision-engineered components that offer exceptional wear resistance and durability. These bushings are made of solid bronze alloy, which is known for its superior strength and corrosion resistance. The addition of self-lubricating materials ensures smooth and efficient operation, even under high loads and temperatures.

The key feature of these bushings is their self-lubricating properties. This eliminates the need for regular lubrication, significantly reducing maintenance requirements and downtime. The self-lubricating material creates a lubricating film that reduces friction and wear, ensuring the bushings maintain their original dimensions and shape for longer periods.

Solid Self-Lubricating Bronze Sleeve Bushings are suitable for a wide range of applications, including heavy machinery, mining equipment, and construction machinery. They can be used in both rotating and oscillating motions, providing superior performance in demanding environments.

In addition to their durability and self-lubricating properties, these bushings also offer excellent dimensional stability and precision. They are manufactured to precise tolerances to ensure they fit perfectly into their intended applications.

Overall, Solid Self-Lubricating Bronze Sleeve Bushings are a reliable and cost-effective solution for applications that require high wear resistance and reduced maintenance. Their superior performance and durability make them an excellent choice for a wide range of industrial applications.

This type of hardened steel bearings are for heavy duty application on the construction engineering machines. For better performance, the hardening of the bushing could be treated with hardening process or special process to achieve an excellent hardness requirement and lubricating characteristics.

Machined cast bronze bearings offer technically and cost-effective bearing solutions.

It is with high load capacity, light weight and good corrosion resistance.

Solid bronze bearings are ideal for demanding applications in challenging environments. This makes the massive bronze bearings ideal for a variety of applications.

![]()

Material

-CuSn7Zn4Pb7

Size

-Customizable

The solid bronze bearings are made from continuously cast bronze CuSn7Zn4Pb7. This material is composed of 85% copper and has very good sliding characteristics. All the surfaces of this plain bearing are machined.

Many other alloys are also available alongside the standard material. The most common among these are CuAl10Ni, CuSn10 and CuSn12.

| Material&Bearing Properties | ||

| Min.Tensile Strength | 230 MPa | 33,300 psi |

| Min.Yield Strength | 130 MPa | 18,800 psi |

| Min.Elongation | 9 % | 9 % |

| Min.Hardness | 60 HB | 60 HB |

![]()

1.There is no need to save the cost and time of oil supply device, oil injection hole, oil tank processing and oil supply device, processing fee, assembly fee, etc., which can greatly reduce the manufacturing cost.

2.The reduction in operating costs significantly reduces the amount of lubricating oil used and the maintenance cost of equipment, and also eliminates the risk caused by insufficient oil supply.

3.In addition, the use of self-lubricating bearings can also improve mechanical properties, extend service life and improve reliability.

4.Recovery and environmental protection of lubricating oil without waste oil recovery treatment is conducive to environmental protection.

Solid bronze bearings are normally lubricated with grease, but the oil is also used in exceptional applications. A good quality lubricant will ensure that friction and wear are reduced by forming a film between the plain bearing and the shaft. For highly contaminated applications, we recommend sealing the bearing. This will protect the bearing and lubricant.

All solid bronze bearings with an inner diameter of 14 mm or more are provided with an axial lubrication groove.

![]()

Properties | Value |

Max. load (Dyn/stat), N/mm2 | 25 / 45 |

| Max. sliding speed m/s | 0.5 |

| Max. PV value N/mm2 x m/s | 2.8 |

| Temperature range, oC | +250 (depending on type of lubricant) |

| Shaft tolerance | e7 - e8 |

| Housing tolerance | H7 |

| Shaft roughness | Ra ≤ 1.0 |

| Shaft hardness | > 165 HB |

1.Where possible, design to standard specifications.

2. Please pay attention to the presence of foreign matter on the surface during assembly.

3. After use, the sliding surface, due to the oil film formed by solid lubricant, has black or grey black phenomenon, please do not scrub, use as usual;

4. Before assembly, if the lubricating oil is applied to the grinding parts, it can reduce the running and closing period, which is conducive to the mechanical operation and operation;

5. During assembly, the bearing should be pressed in slowly, and no knocking is allowed, so as not to damage the bearing and cause deformation.

6. In the design, different parts should be selected appropriate material, in order to improve the mechanical performance, extend the service life of the bearing;

7. In high bearing, reciprocating motion, screw fixation is recommended;

8. Stainless steel or chrome plating is recommended for grinding shafts in fresh water, sea water and at sea.

1.The highest security performance

2.To prevent the vibration and dynamic load caused by loosening

3.Easy to install and remove

4.Locking effect is not affected by lubrication

5.Regardless of the level of the pre tightening force has a good locking effect

6.Can control the level of pre tightening force

7.The same temperature characteristics with the standard bolt / nut

8.Can be used repeatedly

Solid bronze bearings are ideal for applications involving both axial and radial oscillatory movements.Common applications are:

·Offshore

·Dredging industry

·Mechanical engineering

·Elevators

It is used in many industries: excavators, cranes and some important parts of construction equipment, etc.

If you have any questions, please feel free to contact us,you are always welcome, thank you!