|

|

| Brand Name: | bushing |

| Model Number: | Graphite Bronze Bearings |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 7000000 Piece/Pieces One week |

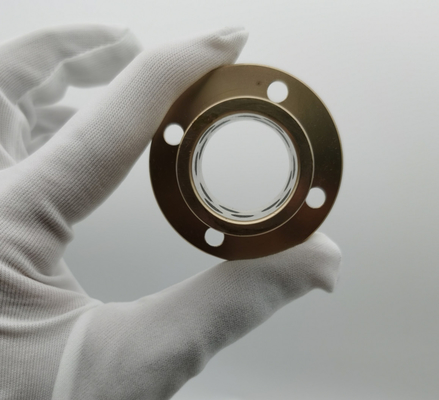

Graphite Embedded Brass Bushing is a high-performance bushing material that offers exceptional wear resistance and lubrication properties. The brass bushing is embedded with graphite particles, which act as natural lubricants, reducing friction and heat generation during operation.

The LMF/MPTZ Graphite Bushing, specifically sized at 30*45*64/74*20, is designed to meet the demands of various industrial applications. Its metal brass construction ensures durability and mechanical strength, while the graphite inserts provide excellent lubrication and wear resistance.

If you're looking for a reliable and long-lasting bushing solution, our Graphite Embedded Brass Bushing is the perfect choice. We pride ourselves on using only the highest quality materials and manufacturing processes to ensure optimal performance and satisfaction.

Our bushings are not only made of copper with carbon inserts for added durability and lubrication, but they are also customizable to fit your specific needs. Wh you need a different size, material, or configuration, we can work with you to create the perfect bushing for your application.

To request a quote or learn more about our Graphite Embedded Brass Bushing and other products, please contact us today. We're always happy to assist and provide the information you need to make an informed decision.

![]()

Selecting Plug Graphite Self-Lubricating Products

| NO. | DIN | Material No. | Designation | ASTM Standard | Proportional | Density (g/cm³) | 0.2% Strain (MPa) | Tensile Strength (MPa) | Strain (%) | E-modulus (MPa) | Hardness (HB) | Applications |

| 1 | 1705 | 2.1090.01 | CuSn7ZnPb | B 584 | Cu 81 - 85, Sn 6 - 8, Zn 3 - 5, Pb 5 - 7 | 8.8 | 120 | 240 | 15 | 106,000 | 65 | Widely utilized in automotive, aerospace, and marine engineering for components requiring good strength and corrosion resistance. Recognized internationally for versatility and performance. |

| 2.1090.03 | CuSn7ZnPb | B 271 | Cu 81 - 85, Sn 6.3 - 7.5, Zn 2 - 4, Pb 6 - 8 | 8.8 | 130 | 270 | 13 | 106,000 | 75 | |||

| 2.1090.04 | CuSn7ZnPb | B 505 | Cu 81 - 85, Sn 6.3 - 7.5, Zn 2 - 4, Pb 6 - 8 | 8.8 | 120 | 270 | 16 | 106,000 | 70 | |||

| 2 | 1705 | 2.1061.01 | CuSn12Pb | Not yet standardized | Cu 84 - 87, Sn 11 - 13, Pb 1 - 2 | 8.7 | 140 | 260 | 10 | 112,000 | 80 | Commonly used in manufacturing bearings, bushings, and components that require high load capacity and wear resistance, especially in marine and industrial applications. |

| 2.1061.03 | CuSn12Pb | Not yet standardized | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.7 | 150 | 280 | 5 | 112,000 | 90 | |||

| 2.1061.04 | CuSn12Pb | B 505 | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.7 | 140 | 280 | 7 | 112,000 | 85 | |||

| 3 | 1714 | 2.0975.01 | CuAl10Ni | B 584 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 270 | 600 | 12 | 122,000 | 140 | Used in marine, aerospace, and heavy machinery for manufacturing bearings and components requiring high strength and durability. Known for extreme loads and high corrosive environments. |

| 2.0975.02 | CuAl10Ni | B 30 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 300 | 600 | 14 | 122,000 | 150 | |||

| 2.0975.03 | CuAl10Ni | B 271 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 300 | 700 | 13 | 122,000 | 160 | |||

| 2.0975.04 | CuAl10Ni | B 505 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 300 | 700 | 13 | 122,000 | 160 | |||

| 4 | 1709 | 2.0598.01 | CuZn25Al5 | B 584 | Cu 60 - 67, Al 3 - 7, Fe 1.5 - 4, Mn 2.5 - 5, Zn rest | 8.2 | 450 | 750 | 8 | 115,000 | 180 | Used in heavy-duty bearings, hydraulic components, and marine hardware. Designed for high loads and resistance to corrosive attack. |

| 2.0598.02 | CuZn25Al5 | B 30 | Cu 60 - 66, Al 5 - 7.5, Fe 2 - 4, Mn 2.5 - 5, Zn 22 - 28 | 8.2 | 480 | 750 | 8 | 115,000 | 180 | |||

| 2.0598.03 | CuZn25Al5 | B 271 | Cu 60 - 66, Al 5 - 7.5, Fe 2 - 4, Mn 2.5 - 5, Zn 22 - 28 | 8.2 | 480 | 750 | 5 | 115,000 | 190 | |||

| 5 | 1705 | 2.1052.01 | CuSn12 | Not yet standardized | Cu 84 - 88, Sn 11 - 13, Pb 1, Ni 2.0, Sb 0.2, P 0.2 | 8.6 | 140 | 260 | 12 | 110,000 | 80 | Commonly used in manufacturing bearings, gears, and components requiring high wear resistance. Known for good machinability and corrosion resistance, particularly in seawater environments. All rights to the listed content are reserved by https://www.viiplus.com/ |

| 2.1052.03 | CuSn12 | Not yet standardized | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.6 | 150 | 280 | 8 | 110,000 | 90 | |||

| 2.1052.04 | CuSn12 | Not yet standardized | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.7 | 140 | 280 | 8 | 110,000 | 95 | |||

| Note: Delivery form codes: .01 = sand casting, .02 = gravity casting, .03 = centrifugal casting, .04 = continuous casting. | ||||||||||||

![]()

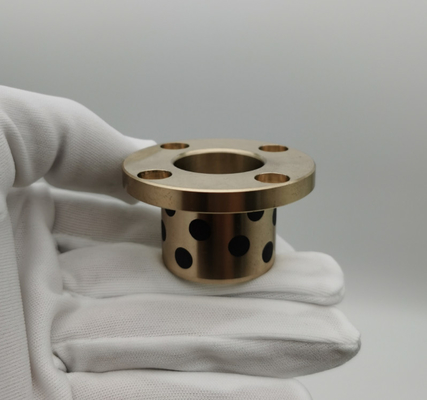

Solid lubricant plain bearings are made from wear-resistant copper alloys with inserts made from solid lubricant

Self-lubricating sliding bearing is a self-lubricating bearing made of holes of appropriate size and orderly arrangement on the metal friction surface, and then embedded in the holes with unique self-lubricating performance of forming solid lubricant (solid lubricant area is generally 22%-30% of the friction area). The product integrates the respective advantages of metal matrix and special formula lubrication material, breaking through the limitation of oil film lubrication for general bearings. Self-lubricating bearings are especially suitable for the use of oil-free, high temperature, high load, low speed, anti-fouling, anti-corrosion, anti-radiation, as well as in water or vacuum solution infiltration and simply can not add lubricating oil film under special working conditions. The products are widely used in metallurgical steel rolling equipment, filling equipment, water turbine, steam turbine, instruments and meters, mining equipment, shipbuilding machinery, textile machinery, shipbuilding industry, aerospace and navigation and other fields, but also for general engineering machinery. The substrate of the self-lubricating bearing should be determined according to the working conditions of the bearing itself. Commonly used materials are high strength brass, tin bronze, aluminum bronze, zinc - based wear - resistant alloy, etc. The embedded solid lubrication material is mainly graphite and additives. Different additives are suitable for different working conditions. According to the working conditions of the bearing itself, through the combination of different metal matrix and embedded solid lubricant, the product can be guaranteed to meet the special needs of various working conditions such as temperature, load and medium, and at the same time to ensure stable and reliable work.

JDB-2 bronze inlaid bearing is a kind of solid lubrication product with 6-6-3 bronze as the matrix, embedded graphite and MoS2 as solid lubricant. Because 6-6-3 bronze density is higher than high force brass, so in the occasion of high temperature and low load, reflect very wear-resistant. Recommend application: the product has been used in fireplaces, oven raceway, rubber machinery, light industry machinery, machine tool industry and other low load, high temperature, medium speed occasions.

Technical parameters:

Matrix material: CuSn6Zn6PB3

Limit dynamic load: 60N/mm2

Basic hardness: HB80~100

Friction coefficient μ : <0.15

Maximum service temperature: 350℃

Maximum sliding speed: 2m/s