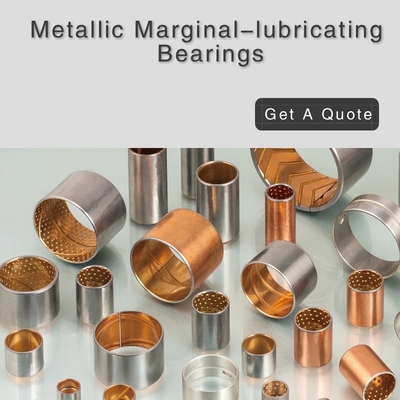

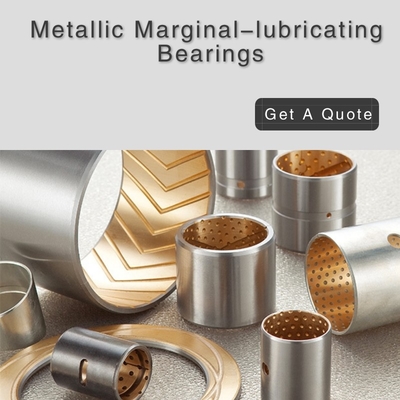

The lead free bronze lead alloys include two different materials. CSB-820 is an alloy with Nickle content and CSB-827 is an alloy with Bismuth content. These materials have low friction coefficients and good wear resistance and they are suitable for lubricated working conditions. To improve the lubricating performance, oil grooves or oil deposits could be optional designs.