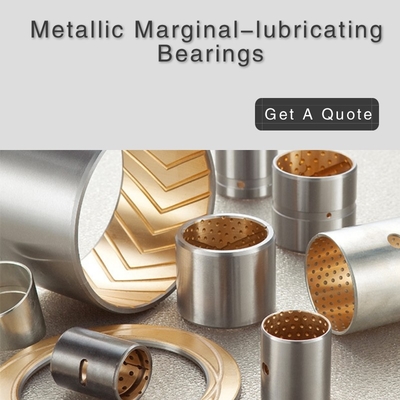

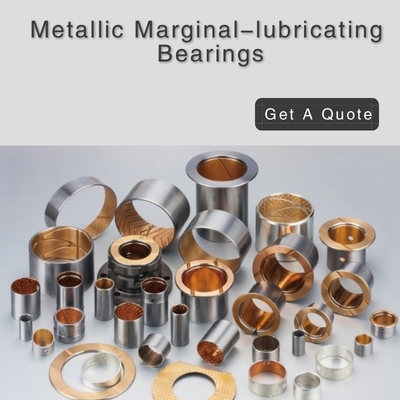

The bronze lead alloy of CSB-800 is CuSb10Pb10, the low lead material CSB-815 with the alloy CuSn10Pb5 is also available. These materials have low friction coefficients and good wear resistance and they are suitable for lubricated working conditions. To improve the lubricating performance, oil grooves or oil deposits could be optional designs.

Bimetal-bearing is a bimetal bearing, wrapped of steel sheets with a layer of lead bronze.

The standard sizes are fitted with lubrication indents on the running surface. For standard bearings is normally the steel backing copper plated to improve the corrosion resistance. The layer of lead bronze makes it possible to use these bearings with relative long lubrication intervals.

Bimetal-bearings can be manufactured with a thicker lead bronze layer for applications where the bearing has to be machined after mounting. The material of the layer can be fitted to the special needs for the application in question.

Special Techincal Features

The internal surface of the bimetal bushes can include different types of channels, so as to satisfy the various types of applications and lubrication conditions in which the bushes may be used.

Structure:

1.Bronze/Aluminum Lead Sintered Alloy, provides good self lubricating feature and has good fatigue resistance and anti-seizure feature.

2.Steel Backing, provides the mechanical strength of the bearing.

![]()

Tech. Data

|

Max. Load |

Static |

250N/mm² |

|

Alloy Hardness |

>70HB |

|

Dynamic |

140N/mm² |

Operation Temperature range |

-40°C~+ 250°C |

||

|

Max. Speed (lubricated) |

2.5m/s |

Friction coefficient |

0.05~0.20 |

||

|

Max. PV |

2.8N/mm²*m/s |

Thermal conductivity |

23W(m*K)-1 |

||

|

Tensile Strength |

350N/mm² |

Coefficient of thermal expansion |

14*10-6*K-1 |

||

Special:

- In- or outside lubrication grooves.

- Several alternative layer materials.

- Without lubrication indents.

- Other positions of tolerance.

- Flat or spherical thrust washers.

- Drawing details.

Typical Applications

These materials are suitable for using under middle load and middle to low speed conditions. The good embeddability of the alloy provides anti-dust feature of the bearings. The bearings can be used under dust environment and where containments existed. The typical applications include connection rods, undercarriage rollers, hydraulic cylinder rod eyes, material handling machinery, agriculture machinery, forest machinery and so on. These two materials are with lead which is restricted to be used for some special parts according the relative laws or regulations.