|

|

| Brand Name: | bronzelube.com |

| Model Number: | Straight Bushing:Bronze with Embedded Solid Lubricant Material,Lead Free |

| MOQ: | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price: | US$0.11 - US$21.11 / Pieces,NEGOTIABLE |

| Payment Terms: | TT IN ADVANCE,L/C,Western Union |

| Supply Ability: | Self Lube Bearing Manufacturing Dimensions Tolerance Assembly |

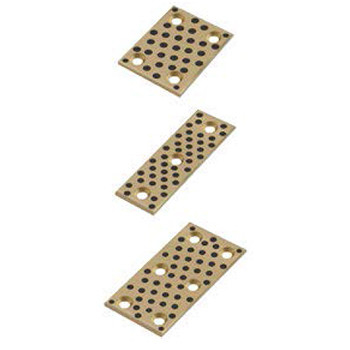

We specialize in manufacturing high-performance graphite bronze wear plates made from the cast bronze alloy C86300. These wear plates are designed to handle heavy loads and provide excellent wear resistance, making them ideal for applications such as cam units and punches in Dayton Moeller machinery.

The C86300 bronze alloy, which is also known as manganese aluminum bronze, offers a unique combination of strength, ductility, and corrosion resistance. The addition of graphite further enhances the wear properties of the material, reducing friction and extending the service life of the wear plates.

Our cast bronze wear plates are precision-engineered to ensure consistent quality and accurate dimensions. They are available in various sizes and thicknesses to meet your specific requirements. Additionally, we offer customization options, allowing you to specify the exact dimensions, graphite content, and other parameters to fit your unique application.

As a trusted supplier of graphite bronze wear plates, we pride ourselves on our commitment to quality and service. We use state-of-the-art manufacturing processes and strict quality control measures to ensure that each wear plate meets the highest standards of performance and durability.

If you are looking for high-quality graphite bronze wear plates for your Dayton Moeller punch or cam unit, we have the perfect solution for you. Contact us today to discuss your requirements and learn more about our products and services.

| Chemical Requirements | ||||||||||||

| Copper Alloy UNS No. |

Composition, % max, except as indicated | |||||||||||

| Nickel | ||||||||||||

| Copper | Tin | Lead | Zinc | Iron | Including | Aluminum | Manganese | Antimony | Sulfur | Phosphorus | Silicon | |

| Cobalt | ||||||||||||

| C86300 | 60.0–66.0 | 0.20 | 0.20 | 22.0–28.0 | 2.0–4.0 | 1.0A | 5.0–7.5 | 2.5–5.0 | ... | ... | ... | ... |

| C90500 | 86.0–89.0 | 9.0–11.0 | 0.30 | 1.0–3.0 | 0.20 | 1.0A | 0.005 | ... | 0.20 | 0.05 | 0.05B | 0.005 |

| C91100 | 82.0–85.0 | 15.0–17.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C91300 | 79.0–82.0 | 18.0–20.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C93700 | 78.0–82.0 | 9.0–11.0 | 8.0–11.0 | 0.8 | 0.7C | 0.50A | 0.005 | ... | 0.50 | 0.08 | 0.10B | 0.005 |

| A In determining copper minimum, copper may be calculated as copper plus nickel. | ||||||||||||

| B For continuous castings, phosphorus shall be 1.5 % max. | ||||||||||||

| C Iron shall be 0.35 % max. when used for steel-backed. | ||||||||||||

![]()

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Product NO. |

Chemical Compositions |

||||||||

VSB-50 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

AVAILABILITY

START YOUR

PROJECTWITH AN APPLICATION ENGINEER

thrust washer&plate inch size