|

|

| Brand Name: | bronzelube.com |

| Model Number: | Bronze Wear Plate:Bronze with Embedded Solid Lubricant Material,Lead Free |

| MOQ: | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price: | US$0.11 - US$21.11 / Pieces,NEGOTIABLE |

| Payment Terms: | TT IN ADVANCE,L/C,Western Union |

| Supply Ability: | Self Lube Bearing Manufacturing Dimensions Tolerance Assembly |

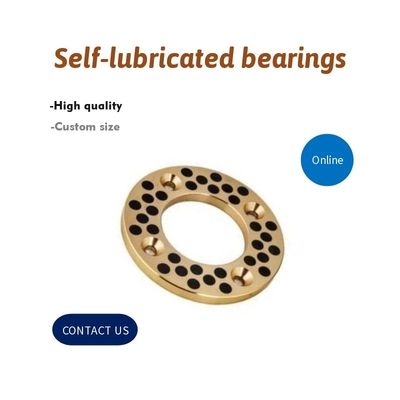

Gasket cast bronze graphite plugged bronze bushings, also known as oilless bearings, are a type of self-lubricating bearing system that utilizes the unique properties of graphite and bronze to provide superior wear resistance and durability.

These bushings are cast from bronze alloy, often C86300, which is a high-tin bronze alloy that offers excellent corrosion resistance and mechanical strength. The graphite plugs or inserts within the bushings provide a continuous lubricating film between the moving surfaces, eliminating the need for external lubrication.

The gasket design of these bushings allows for easy installation and replacement, while also providing a seal against contaminants and moisture. This ensures that the bearings remain in optimal condition, even in harsh environments.

Graphite plugged bronze bushings are commonly used in a wide range of applications, including robotics, heavy machinery, and industrial equipment. They are ideal for applications where lubrication is difficult or undesirable, as well as for applications that require long-term reliability and durability.

In summary, gasket cast bronze graphite plugged bronze bushings, or oilless bearings, offer a self-lubricating bearing solution that provides superior wear resistance, durability, and ease of installation and maintenance.

Our VIIPLUS plain bearings are available in metric and imperial sizes from stock. Our in-house machining service is able to produce non-standard sizes to suit specific customer requirements.

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Product NO. |

Chemical Compositions |

||||||||

TOB 050 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

Type |

Spec. |

Type |

Spec. |

|

|

THRUST WASHER |

PLUGGED GRAPHITE |

30~10.2~3 |

THRUST WASHER |

90~45.2~7 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

40~12.2~3 |

THRUST WASHER |

100~50.3~8 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

40~13.3~3 |

THRUST WASHER |

110~55.3~8 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

50~14.2~3 |

THRUST WASHER |

120~60.3~8 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

50~15.2~3 |

THRUST WASHER |

125~65.3~8 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

50~16.2~3 |

THRUST WASHER |

130~70.3~10 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

50~18.2~3 |

THRUST WASHER |

140~75.3~10 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

50~20.2~5 |

THRUST WASHER |

150~80.3~10 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

55~25.2~5 |

THRUST WASHER |

170~90.5~10 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

60~30.2~5 |

THRUST WASHER |

190~100.5~10 |

|

THRUST WASHER |

PLUGGED GRAPHITE |

70~35.2~5 |

THRUST WASHER |

200~120.5~10 |

|

![]()