|

|

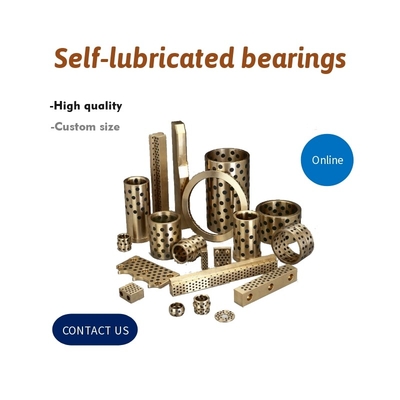

| Brand Name: | bronzelube.com |

| Model Number: | Straight Bushing:Bronze with Embedded Solid Lubricant Material,Lead Free |

| MOQ: | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price: | US$0.11 - US$21.11 / Pieces,NEGOTIABLE |

| Payment Terms: | TT IN ADVANCE,L/C,Western Union |

| Supply Ability: | Self Lube Bearing Manufacturing Dimensions Tolerance Assembly |

Graphite cast bronze bearings are a type of self-lubricating bearing that incorporates solid bronze plates with graphite plugs to achieve the self-lubricating property. Here's how the self-lubrication is realized in these bearings:

Material Composition: The bearing is made from a bronze alloy which is known for its good wear resistance and strength. The bronze is cast with graphite plugs that serve as a source of solid lubrication.

Graphite as a Lubricant: Graphite is a solid lubricant that has a natural ability to reduce friction between sliding surfaces. When the bearing is in motion, the graphite within the bronze matrix transfers to the contact surfaces, creating a thin, low-friction film that helps to reduce wear.

Initial Break-In Period: During the initial operation of the bearing, there is a break-in period where the transfer of material from the bearing to the mating surface occurs. This is a critical step in establishing the self-lubricating film on the contact surfaces.

Ongoing Transfer Process: After the initial break-in, the transfer process continues dynamically throughout the operational life of the bearing. The graphite continues to be transferred to the mating surface, maintaining a lubricating film that reduces friction and wear.

Maintenance-Free Operation: Unlike bearings that require regular application of external lubricants, graphite cast bronze bearings are designed to be maintenance-free. The graphite within the bronze provides a long-lasting source of lubrication, reducing the need for maintenance and extending the service life of the bearing.

Suitability for Various Applications: Due to their self-lubricating nature, graphite cast bronze bearings are suitable for applications where regular maintenance is difficult or where the environment is harsh, such as in high temperatures, contaminated conditions, or where there is a need for a dry-running system.

In summary, the self-lubrication in graphite cast bronze bearings is achieved through the use of graphite as a solid lubricant within the bronze matrix. This combination allows for a continuous transfer of lubricant to the contact surfaces, ensuring reduced friction, wear, and the need for maintenance.

| Composition and properties | ||||||||||||||||

| dg | DIN | Material No. delivery form1) |

Designation | ASTM standard | Proportional weights | Physical properties (min.) | ||||||||||

| Standard | Alloy No. |

DIN | ASTM | Density | 0.2% Strain |

Tensile strength |

Strain | Emodulus | Hardness | Application | ||||||

| Symbol | ρ | δy | δT | |||||||||||||

| Unit | % | % | g/cm³ | MPa | MPa | % | MPa | HB | ||||||||

| 01 | 1705 | 2.1090.01 | CuSn7ZnPb | B 584 | C932 00 | Cu 81 - 85 Sn 6 - 8 Zn 3 - 5 Pb 5 - 7 permissible max. portions Ni 2.0 Sb 0.3 |

Cu 81 - 85 Sn 6.3 - 7.5 Zn 2 - 4 Pb 6 - 8 Ni 1 Sb 0.35 |

8.8 | 120 | 240 | 15 | 106.000 | 65 | Standard material for the most applications international standardized |

||

| 2.1090.03 | CuSn7ZnPb | B 271 | C932 00 | 8.8 | 130 | 270 | 13 | 106.000 | 75 | |||||||

| 2.1090.04 | CuSn7ZnPb | B 505 | C932 00 | 8.8 | 120 | 270 | 16 | 106.000 | 70 | |||||||

| 02 | 1705 | 2.1061.01 | CuSn12Pb | not yet standardized | Cu 84 - 87 Sn 11 - 13 Pb 1 - 2 permissible Ni 0.8 - 1.5 max. portions Ni 2.0 Sb 0.2 P 0.2 |

Cu 85 - 88 Sn 10 - 12 Pb 1 - 1.5 |

8.7 | 140 | 260 | 10 | 112.000 | 80 | Material for high loads and/or corrosion stress attack international only partially standardized |

|||

| 2.1061.03 | CuSn12Pb | not yet standardized | 8.7 | 150 | 280 | 5 | 112.000 | 90 | ||||||||

| 2.1061.04 | CuSn12Pb | B 505 | C925 00 | 8.7 | 140 | 280 | 7 | 112.000 | 85 | |||||||

| 03 | 1714 | 2.0975.01 | CuAl10Ni | B 584 | C955 00 | C u min. 75 Al 8.5 - 11.0 Ni 4.0 - 6.5 Fe 3.5 - 5.5 permissible max. portions Mn 3.3 |

Cu min. 78 Al 10 - 11.5 Ni 3 - 5.5 Fe 3 - 5 Mn max. 3.5 |

7.6 | 270 | 600 | 12 | 122.000 | 140 | Material for extreme loads and/or high corrosive environments international standardized |

||

| 2.0975.02 | CuAl10Ni | B 30 | C955 00 | 7.6 | 300 | 600 | 14 | 122.000 | 150 | |||||||

| 2.0975.03 | CuAl10Ni | B 271 | C955 00 | 7.6 | 300 | 700 | 13 | 122.000 | 160 | |||||||

| 2.0975.04 | CuAl10Ni | B 505 | C955 00 | 7.6 | 300 | 700 | 13 | 122.000 | 160 | |||||||

| 04 | 1709 | 2.0598.01 | CuZn25Al5 | B584 | C863 00 | Cu 60 - 67 Al 3 - 7 Fe 1.5 - 4 Mn 2.5 - 5 Zn rest permissible max. portions Ni max. 3 |

Cu 60 - 66 Al 5 - 7.5 Fe 2 - 4 Mn 2.5 - 5 Zn 22 - 28 Ni max. 1 |

8.2 | 450 | 750 | 8 | 115.000 | 180 | Material for highest loads without corrosive attack. international partially standardized to a large extend |

||

| 2.0598.02 | CuZn25Al5 | B 30 | C863 00 | 8.2 | 480 | 750 | 8 | 115.000 | 180 | |||||||

| 2.0598.03 | CuZn25Al5 | B 271 | C863 00 | 8.2 | 480 | 750 | 5 | 115.000 | 190 | |||||||

| 05 | 1705 | 2.1052.01 | CuSn12 | not yet standardized | Cu 84 - 88 Sn 11 - 13 Pb 1 Ni 2.0 Sb 0.2 P 0.2 |

Cu 85 - 88 Sn 10 - 12 Pb 1 - 1.5 Ni 0.8 - 1.5 |

8.6 | 140 | 260 | 12 | 110.000 | 80 | Material with good wear resis- tance. corrosion and seawater resistant international partially standardized |

|||

| 2.1052.03 | CuSn12 | not yet standardized | 8.6 | 150 | 280 | 8 | 110.000 | 90 | ||||||||

| 2.1052.04 | CuSn12 | not yet standardized | 8.7 | 140 | 280 | 8 | 110.000 | 95 | ||||||||

| 1 ) delivery form: .01 = sand casting. .02 = gravity casting. .03 = centrifugal casting. .04 = continuous casting | ||||||||||||||||

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Product NO. |

Chemical Compositions |

||||||||

VSB-50 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

![]()

START YOUR

PROJECTWITH AN APPLICATION ENGINEER