|

|

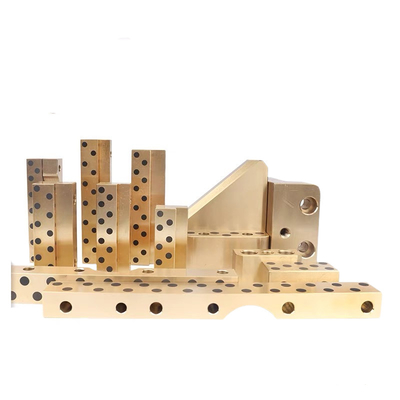

| Brand Name: | bronzelube.com |

| Model Number: | Wear Plates - SelfLube Mold and Die Products |

| MOQ: | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price: | US$0.11 - US$21.11 / Pieces,NEGOTIABLE |

| Payment Terms: | TT IN ADVANCE,L/C,Western Union |

| Supply Ability: | Self Lube Bearing Manufacturing Dimensions Tolerance Assembly |

Introducing our self-lubricating slide plate specifically designed for metal stamping dies with a 45-degree angle. This innovative slide plate is engineered to provide exceptional lubrication and wear resistance, ensuring smooth and efficient operation during metal stamping processes.

The slide plate is made from high-quality materials that exhibit self-lubricating properties, reducing the need for external lubrication and maintenance. This feature not only simplifies the stamping process but also extends the lifespan of the die and slide plate, reducing downtime and operational costs.

The 45-degree angle of the slide plate allows for precise alignment and easy integration into metal stamping dies. It ensures a secure and stable fit, providing optimal support and guidance for the stamping process.

Wh you're looking to replace worn-out slide plates or upgrade your existing metal stamping equipment, our self-lubricating slide plate with a 45-degree angle is an excellent choice. It offers reliable performance, durability, and ease of maintenance, making it a cost-effective solution for metal stamping applications.

Ordinary slant wedge mechanism, the slider is generally attached to the lower die, so that the design and movement is relatively simple, but in some cases, when the slider is attached to the lower die, the feeding and removal of the parts is not convenient, or affect the realization of other functions of the mold, then the hanging wedge mechanism should be considered, according to the movement of the slider, the slant wedge mechanism can be divided into flat slant wedge mechanism and inclined slant wedge mechanism (mold body and slider contact surface for the slant) .

The name of inclined wedge

Code - work mounting surface (W) - stroke (ST) - angle of the slanting wedge (θ ) - fixed mode (K for key positioning, N for pin positioning)

The advantages and disadvantages of the various types of wedges commonly used

a,Horizontal slanting wedge: it is necessary to fully consider the problem of taking out the parts.

b, hanging wedge: good workability, but the edge of the research and matching difficulties.

c, double-action wedge: occupy more space, and complex structure, for the strength of the mold has an impact (rotary wedge alternative).

The oblique wedge mold oblique wedge stroke design should express the content

1) the stroke of the slanting wedge slider: ST

2)Slanting wedge stroke:L

3)Slanting wedge operating stroke:W

4)Stroke of slant wedge press plate:C

5)Slanting wedge angle:θ

6)Start point of upper press core action:P

7) Upper and lower die guide engagement point: G

Return mode of sliding wedge

a) Spring

b) Polyurethane rubber

c) cylinder

d) Nitrogen spring

e) Other methods

In general, springs are used as the source of return force, but other return methods such as cylinders are used in the following cases.

a) the stroke of the tilt wedge is relatively long, the spring can not meet the stroke requirements

b) double-action tilt wedges, which need to be repositioned.

General considerations.

1) When installing the spring and cylinder to the slant wedge die slider, according to its installation position, the slant wedge slider movement moment, the set slider needs to consider the following to obtain the overall balance

a) As close as possible to the slide guide surface (height direction)

b) Installed as close as possible to the guide rail at both ends of the wedge slider (horizontal direction)

(2) the mold structure must be designed to take into account the premise that the maintenance spring or cylinder can be replaced without dismantling the large components of the mold.

The principle of determining the return force of the slanting wedge slider

Horizontal slant wedge mold

(Total weight of sliding wedge*1.0) or more

Inclined wedge die

(Total weight of sliding wedge * 1.5) or more

For the part of the self-made slanting wedge, because of the wide range of aspects involved, need to consider more comprehensive issues, here is not a detailed description (specific by the cold workers or gold assistant to explain)

The design of standard bevel wedge mold

On the premise of having the part process diagram and 3D digital model

can be designed by the following steps.

1) Firstly, make a straight line normal to the hole (see the figure below)

2) Secondly, project the straight line on the XY plane (on the mold base) to determine the angle of the standard bevel wedge, the actual measured angle is: 8°, there is no such specification in the standard bevel wedge, the approximation is to take a very close specification: 10° bevel wedge.

b) Determine the placement angle of the swash wedge on the mold plane

Again project the projection line on the YZ plane to determine the placement angle of the standard bevel wedge, the measured value is: 10 ° (need to pay attention to the capacity of each company's processing machine tool, wh it can be processed at any angle or has a special angle requirements)

C) Determine the installation height and position of the swash wedge through the cross section

1) The position of the punch is determined and the angle and position of the concave die set and the anti-rotation angle are accurately determined;

2) The wedge is placed according to the angle of placement on the die holder and the position of the punch holder.

D) Select the installation method of the punch holder according to the actual situation of the die.

From the angle of balance of force on the sliding wedge, the most ideal fixing method is to control the force point of the punch as much as possible on the center of the sliding wedge, and the installation method of the fixing seat is arranged according to the actual situation in special cases; the approximate position of the sliding wedge on the die holder is determined according to the fixing angle of the punch fixing seat.

E)According to the fixed position and cross-sectional drawing of the bevel wedge slider and punch fixing seat, the mounting height and plane position of the bevel wedge are determined, and the mounting height and plane coordinate size of the bevel wedge are integers (0 and 5 at the end) as far as possible.

F) When designing the standard inclined wedge die, the following matters are to be considered since the stroke of the inclined wedge has been fixed.

Ordinary inclined swash wedge.

Since the working part is fixed on the lower die, it should be considered that the parts can be fed smoothly; its stroke should ensure that it is not less than the width of the edge of the flange + the distance of the flange bevel wedge trimming or punching or flanging + 20~30mm (Note: 30mm if it is automated stamping, it should be 50mm when it is manually operated)

Lift bevel wedge slider stroke.

The distance from the flange to the trimming, punching or flanging of the bevel wedge +20mm;

Lifting of the bevelled wedge requires consideration of wh the working components installed on the slider (punch, side trimmer block, flanging block) affect the assembly and disassembly of the press core; and wh there is sufficient space for grinding between the bevelled wedge and the press core.

G)Disposal of scrap

1) the scrap through the hole as large as possible.

2)Sometimes in order to prevent the scrap from blocking, the scrap of the side punching hole needs to increase the top material device.

3) castings to design the scrap slide over hole to fully consider the width of the maximum size of the scrap if it occurs after rotation.

4) If the scrap is too long, consider increasing the scrap knife to achieve a smooth slide out of the scrap and increase the strength of the mold.

5) To use the flexible ejector pin convex (concave) die in the following cases.

a) in order to make the scrap slide out piece by piece.

b) want to control the state of the scrap when it falls.

6)If there is a rebound of the scrap.

a) the knife into the mold amount to be large.

b) need to install the scrap ejector device.

7) The following cases need to increase the guide device.

a) there is no empty space on the waste exclusion side, it must be transformed into a vertical fall in a right-angle direction, with a vertical aperture of at least two times the diameter of the punch.

b) If the hole is punched on both sides at the same time, it is necessary to increase the dividing pin.

H) Classification of the standard diagonal wedge die presser.

The press is used to prevent the positioning and deformation of the parts, and can be divided into three types according to the shape and number of action directions.

a) Upper compression material core

The advantages are: the compression force is relatively large, so you don't have to worry about the deformation of the parts; close to the vertical wall and near the end of the side wall, separated by the upper compression core.

b) Slanting wedge side compression core

c) Side compression material and positive compression material share

Insufficient compression force of the side compression material.

Unstable parts.

the positive press material should be pressed 10mm earlier than the side press material on the part.

I) Positioning and anti-lateral force of the slanting wedge

(b) The bevel wedge has two types of pin positioning and key positioning.

(b) A side trimming and flanging, with thicker material requiring measures to prevent lateral forces.

Measures and forms to prevent lateral forces.

Addition of guiding devices.

Translated with www.DeepL.com/Translator (free version)

Copper alloy+Special solid lubricant

Oil-Free Slide Plate (10mm)

Oil-Free Slide Plate for universal use in many dry applications such as die/mold, machinery, automation, construction, automobile. Oil-Free is self-lubrication and work without grease.

Self Lubricating Bronze Wear Plate, bronze slide plates, slide plates, Oil-free slide plates.

Many of the fully machined bronze Oil-free slide plates with copper alloys wear plates that we manufacture are self-lubricating. This is achieved by a process of plugging the bronze plate with plugs of graphite. We offer a full line of plug graphite bearings. More information on our graphite plugged parts can be found here.

Wear Plates - SelfLube Mold and Die Products, plugged graphite bronze Oil free slide plates with copper alloys wear plates are available in a broader range of sizes.

custom configurations for special sizes, hole patterns, or graphite patterns.made in china. Cast Bronze Wear Plate Oil-free slide plates with copper alloys

Our Cast Bronze Wear Plate is produced by a method known as continuous casting. The fine grain structure obtained through continuous casting virtually eliminates casting defects associated with static casting methods. This dense structure is free from porosity which in turn prolongs the life of your tooling.

Self Lube Wear Plates Oil-free slide plates with copper alloys Cam Slide Guide, PLUG GRAPHITE BRONZE BUSHINGS Maintenance-free Plain Bearings lamina gib slides.

Easy to install, highly durable. Its optimized design allows for easy installation, low noise operation, space savings, and extended service life for bronze bushings.

Slide elements/Cam components/Cam units/Plastic mold components

Solid Bronze Metallic Self Lubricating Bearing | Flanged Bronze Bushings

Cast Bronze Sleeve (Plain) Bearings. Standard sliding bearing stock size.

These standards provide off-the-shelf economy for most applications

C90300 BRONZE GRAPHITE BUSHINGS is a “GREEN” non-leaded alloy

Tin Bronze BUSHINGS – Navy G QQC-390B Type II and Type III

CDA 903 SAE 620 88-8-0-4 ASTM B505

Casting Tin Bronze SAE 620 |

||||||||||

Element |

||||||||||

Cu(1,2) |

Pb |

Sn |

Zn |

Fe |

P(3) |

Ni(4) |

Al |

S |

Sb |

Si |

Min (%) |

86 |

|

7.5 |

3 |

|

|

|

|

|

|

Max (%) |

89 |

0.3 |

9 |

5 |

0.2 |

0.05 |

1 |

0.005 |

0.05 |

0.2

|

VIIPLUS CAST BRONZE BUSHINGS of C90300 give superior quality and performance. Continuous casting achieves a high-density grain structure, free of porosity, resulting in a reduction of tool wear and component rejects.

Solid bars are stocked 13" increments and 105" lengths, and are available in other lengths and nonstandard sizes. Consider bars for use when you need special bearings, bearings for prototypes, or for emergency repairs.

|

|

Element |

||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Cu(1,2) |

Pb |

Sn |

Zn |

Fe |

P(3) |

Ni(4) |

Al |

S |

Sb |

Si |

|

|

|

|||||||||||

|

Min (%) |

86.0 |

|

7.5 |

3.0 |

|

|

|

|

|

|

|

|

Max (%) |

89.0 |

0.30 |

9.0 |

5.0 |

0.20 |

0.05 |

1.0 |

0.005 |

0.05 |

0.20 |

0.005 |

C90300 TIN BRONZE Bushings.

Copper, Brass, and Bronze Alloys fromVIIPLUS INTERNATIONAL

BS 1400 (LG1, LG2, LG4, LG3, PB1, PB2, PB3, PB4, LPB1, LB1, LB2, LB3, LB4, AB1, AB2, HTB3, HTB1)

UNS (C62500, C83600, C84400, C86200,C86300, C87200, C90700, C93200, C93700, C93800, C95200, C95500)

BS EN (CC490K, CC491K, CC493K, CC480K, CC483K, CC482K, CC495K, CC496K, CC331G, CC333G, CC762S, CC764S).

|

Related Specifications & Applications for Common Casting Copper Alloys |

|||||

|

Alloy Description |

American Spec. |

American Spec. |

German Spec. |

British Spec. |

Typical Material Applications |

|

UNS |

SAE |

alloy |

alloy |

||

|

Cu85 Sn5 Zn5 Pb5 |

C83600 ( CDA 836) |

40 |

CuSn5ZnPb |

LG2 |

Pump components, small gears, bearings, impellers, flanges, low-pressure valves, and fittings. |

|

Cu83 Sn3 Zn8 Pb6 |

C84400 (CDA 844) |

- |

CuSn2ZnPb |

*LG1 |

Light duty bearings, general hardware, fixtures, low-pressure valves, and fittings. |

|

Cu63 Al6 Fe3 Mn3 Zn25 |

C86300 (CDA 863) |

430B |

- |

- |

Heavy-duty high strength alloy for gears, cams, slow speed heavy load bearings, screw-down nuts. |

|

Cu88 Sn8 Zn4 |

C90300 ( CDA 903) |

620 |

- |

- |

Bearings, bushings, piston rings, valve components, seal rings, steam fittings, and gears. |

|

Cu88 Sn10 Zn2 |

C90500 ( CDA 905) |

62 |

CuSn10Zn |

*G1 |

Marine pumps, valves, bearings, bushings, piston rings, steam fittings and gears. |

|

Cu89 Sn11 |

C90700 ( CDA 907) |

65 |

CuSn12 |

*PB1 |

Heavy-duty gears, high load bearings, bushings, and worm wheels. |

|

Cu88 Sn6 Zn4 Pb2 |

C92200 ( CDA 922) |

622 |

- |

LG3 |

Valves, fittings, Medium-pressure hydraulic and steam pressure parts for use up to 550 F (287 C) |

|

Cu87 Sn11 Ni2 |

C92500 ( CDA 925) |

640 |

CuSn12Ni |

CT2 |

Gears, worm wheels - Good shock resistance, Automotive synchronizer rings. |

|

Cu87 Sn11 Pb2 |

C92700 ( CDA 927) |

63 |

CuSn12Pb |

LB3 |

Heavy-duty bearings, bushings, piston rings, valve components, steam fittings, gears. |

|

Cu83 Sn7 Zn3 Pb7 |

C93200 ( CDA 932) |

660 |

CuSn7ZnPb |

|

General utility bearings, bushings, and wear plates for medium speeds and pressures. |

|

Cu85 Pb10 Sn5 |

C93500 ( CDA 935) |

66 |

- |

LB4 |

high-speed bearings, bushings, high-speed light loading, and light pressure parts. |

|

Cu80 Pb10 Sn10 |

C93700 ( CDA 937) |

64 |

CuPb10Sn |

LB2 |

Bearings for high speed and heavy pressures, pump parts, pressure-tight castings. |

|

Cu78 Pb15 Sn7 |

C93800 ( CDA 938) |

67 |

CuPb15Sn |

LB1 |

Turbocharger bearings, bearings for general service and moderate pressures, railroad applications. |

|

Cu87 AI10 Fe3 |

C95400 ( CDA 954) |

- |

CuAI10Fe |

- |

High strength bearings, bushings, gears, worms, wear plates, valve seats, and guides. |

|

Cu81 AI10 Ni5 Fe4 |

C95500 ( CDA 955) |

- |

CuAI10Ni |

- |

High strength bearings, corrosion-resistant parts, aircraft valve guides, and seats. |

|

Cu80 AI10 Ni6 Fe4 |

C95800 ( CDA 958) |

- |

CuAl10Ni |

AB2 |

Anti-fouling saltwater corrosion-resistant parts and general marine hardware. |

|

Phosphor Bronze Grade I |

C54400 |

|

CuSn4 |

PB101 |

|

|

Phosphor Bronze Grade I |

C54400 |

CuSn4 |

PB101 |

|

Phosphor Bronze Grade II |

C51000 |

CuSn5 |

PB102 |

|

Phosphor Bronze Grade III |

C51900 |

CuSn6 |

PB103 |

|

Phosphor Bronze |

C52100 |

CuSn8 |

PB104 |

![]()

As a professional special copper alloy production plant, the company controls the chemical composition, mechanical properties, physical properties, and other properties of materials with strict internal standards.

The company produces the corresponding bronze alloy according to the relevant brand standards of China and foreign countries, with excellent performance and short delivery time.

The company's existing product brands: qsn6.5-0.1, qsn7-0.2, qsn8-0.3, ZCuSn10P1, ZCuPb10Sn10, ZCuPb15Sn8, ZCuPb20Sn5, ZCuSn5Pb5Zn5, ZCuSn6Zn6 Pb3, C54400, C84400, C93200, C93700, C93800, etc.

According to the national standard, American standard, German standard, and other customer standards for custom.

Products type: copper rod, copper tube, including shaped tube, rod.

![]()

Product Description: Manganese Bronze bushing

This product is made of high strength brass CuZn25Al6Fe3Mn3 with a special formula, which has high mechanical properties, good casting performance, and good corrosion resistance in air, freshwater, and seawater. The products are widely used in continuous casting machines, mining machinery, ships, gas turbines, and so on.

Bearing is an important part of the steam turbine, which is divided into radial support bearing and thrust bearing. They are used to bear all the gravity of the rotor and determine the correct position of the rotor in the cylinder.

VSB-50 is a self-lubricating bearing material that consists of a high-quality bearing bronze with pockets filled with solid lubricant and a thin film of solid lubricant over the bearing surface to aid the running-in process. VSB-50 maintenance-free bearings, without the need for lubrication with oil or grease, are recommended for large bearings. have a low coefficient of friction

Copper alloy inlaid self-lubricating bearing (foreign says deva. Glide) is based on copper alloy substrate, on the friction surface according to a certain proportion to drill out the appropriate size, arranged orderly several holes (diameter phi d 200 mm or less) or blind hole (diameter phi d > 200 mm), the embedded in the hole with a unique lubricating solid lubricant by the precision machining of a kind of high-performance self-lubricating bearings.

It breaks through the limitations of ordinary bearings depending on oil film lubrication, especially suitable for non-oil, high temperature, high load, low speed, anti-fouling, anti-corrosion, anti-radiation, as well as in water or vacuum solution infiltration and no oil lubrication or lubrication difficult under special working conditions.

VSB-50W WASHER Thrust washers PAW

——Suitable for low speed, heavy load or intermittent movement conditions, lubricating oil film can not form or maintain the occasion;

——Suitable for work environment or mechanical structure restrictions, it is difficult to supply oil lubrication occasions;

——Suitable for occasions where impact loads are easy to occur in the work;

——Suitable for rotating, reciprocating, swinging and linear and other forms of movement and need to start frequently or under high load starting occasions;

——Suitable for high or low-temperature work, or the environment temperature range of large occasions;

——Suitable for long maintenance cycle or high maintenance cost, require long service life of the bearing occasions;

——Good corrosion resistance can be used in seawater and other chemical liquids or gases and other corrosive media;

——No water absorption, good dimensional stability, high mechanical strength, with good thermal conductivity;

——Under the condition of medium load, medium speed, lubrication, mixed lubrication can be achieved, prolong the service life;

VSB-50W WASHER material is made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/low temperature at low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent of oscillating motion.

|

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

|

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

|

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

|

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

|

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

|

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

|

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

|

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

|

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

|

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

|

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

|

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

|

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

|

Product NO. |

Chemical Compositions |

||||||||

|

TOB 050 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

|

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designs