|

|

| Brand Name: | VIIPLUS |

| Model Number: | bronze wear plate |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | bronze wear plate |

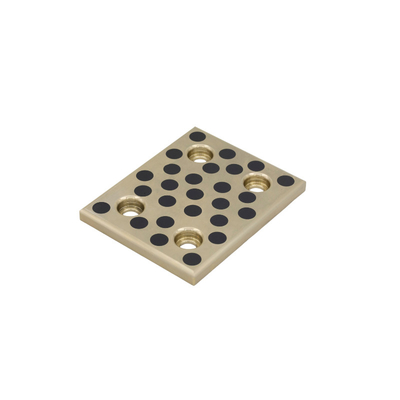

The STW Self-Lubricant Graphite Sliding Plate is designed to operate without the need for external oil lubrication, making it an ideal solution for various applications requiring low friction and high durability. This sliding plate incorporates graphite, a naturally occurring mineral known for its exceptional lubricity, to provide a smooth and wear-resistant surface that requires no additional lubrication.

The use of graphite as the self-lubricant material ensures that the sliding plate can operate efficiently and reliably in environments where traditional oil-based lubrication may not be feasible or practical. This feature eliminates the need for regular lubrication maintenance, reducing downtime and operational costs.

Furthermore, the STW Self-Lubricant Graphite Sliding Plate is engineered to withstand high temperatures and pressures, making it suitable for use in demanding industrial applications. Its durability and longevity are enhanced by the use of high-quality materials and precision manufacturing techniques.

In summary, the STW Self-Lubricant Graphite Sliding Plate offers a reliable, oil-free solution for applications requiring smooth, low-friction sliding surfaces. Its self-lubricating properties, combined with its resistance to wear and high-temperature capabilities, make it an excellent choice for a wide range of industrial and mechanical applications.

self lubricate guide plate, Mould & Die, Oil-free slide plate SEW38-200 metric size material copper alloy special solid lubricant embedded, sliding plate, plugged graphite plate, oilless slide plates.

![]()

| STW2875 | 10 | 28 | 75 | Bronze/Graphite Plate |

| STW28100 | 10 | 28 | 100 | Bronze/Graphite Plate |

| STW28125 | 10 | 28 | 125 | Bronze/Graphite Plate |

| STW28150 | 10 | 28 | 150 | Bronze/Graphite Plate |

| STW3875 | 10 | 38 | 75 | Bronze/Graphite Plate |

| STW38100 | 10 | 38 | 100 | Bronze/Graphite Plate |

| STW38125 | 10 | 38 | 125 | Bronze/Graphite Plate |

| STW38150 | 10 | 38 | 150 | Bronze/Graphite Plate |

| STW4875 | 10 | 48 | 75 | Bronze/Graphite Plate |

| STW48100 | 10 | 48 | 100 | Bronze/Graphite Plate |

| STW48125 | 10 | 48 | 125 | Bronze/Graphite Plate |

| STW48150 | 10 | 48 | 150 | Bronze/Graphite Plate |

| STW48200 | 10 | 48 | 200 | Bronze/Graphite Plate |

| STW5875 | 10 | 58 | 75 | Bronze/Graphite Plate |

| STW58100 | 10 | 58 | 100 | Bronze/Graphite Plate |

| STW58150 | 10 | 58 | 150 | Bronze/Graphite Plate |

| STW7575 | 10 | 75 | 75 | Bronze/Graphite Plate |

| STW75100 | 10 | 75 | 100 | Bronze/Graphite Plate |

| STW75125 | 10 | 75 | 125 | Bronze/Graphite Plate |

| STW75150 | 10 | 75 | 150 | Bronze/Graphite Plate |

| STW75200 | 10 | 75 | 200 | Bronze/Graphite Plate |

| STWT100100 | 10 | 100 | 100 | Bronze/Graphite Plate |

| STWT100125 | 10 | 100 | 125 | Bronze/Graphite Plate |

| STWT100150 | 10 | 100 | 150 | Bronze/Graphite Plate |

| STWT100200 | 10 | 100 | 200 | Bronze/Graphite Plate |

| STWT100250 | 10 | 100 | 250 | Bronze/Graphite Plate |

| STWT125150 | 10 | 125 | 150 | Bronze/Graphite Plate |

| STWT125200 | 10 | 125 | 200 | Bronze/Graphite Plate |

| STWT125250 | 10 | 125 | 250 | Bronze/Graphite Plate |

| STWT150150 | 10 | 150 | 150 | Bronze/Graphite Plate |

| STWT150200 | 10 | 150 | 200 | Bronze/Graphite Plate |

| STW100100 | 10 | 100 | 100 | Bronze/Graphite Plate |

| STW100125 | 10 | 100 | 125 | Bronze/Graphite Plate |

| STW100150 | 10 | 100 | 150 | Bronze/Graphite Plate |

| STW100200 | 10 | 100 | 200 | Bronze/Graphite Plate |

| STW100250 | 10 | 100 | 250 | Bronze/Graphite Plate |

| STW125150 | 10 | 125 | 150 | Bronze/Graphite Plate |

| STW125200 | 10 | 125 | 200 | Bronze/Graphite Plate |

| STW125250 | 10 | 125 | 250 | Bronze/Graphite Plate |

| STW150150 | 10 | 150 | 150 | Bronze/Graphite Plate |

| STW150200 | 10 | 150 | 200 | Bronze/Graphite Plate |

We are professional Bronze Bushing wear plate manufacturer and we can make all kinds of oillless slide plates based on standards.

Self lubricant graphite sliding plate Advantages:

Bronze Bushing plate manufacture & export

Advanced CNC machine to guarantee the tolerance and good appearance

Strictly QC checking to guarantee good quality

Fast delivery

If you had any requirement of Bronze Bushing plate, please contact us TODAY!

High strength brass, chemical formula is ZCuZn25Al6Fe3Mn3, mechanical properties are different zinc content, mechanical properties are also different, pressure processing performance has good plasticity, can withstand hot and cold processing.

Bronze Wear Plates guide and control linear movement where there are heavy forced to contend with. These plates are acting as linear bearings to control movements. bronzegleitlager.com offers wide range of bronze wear plates. Below are descriptions of the various

![]()

A self-lubricating plate is a metallic component with high porosity (20-

Bronze Bushing wear plates is made of bronze or steel base material with graphite inlaid.It’s also called Bronze Bushing guide bar, oiless bronze plates and etc.

Standard material: CuZn25A16Fe3Mn3 + Graphite;

Other customized materials can be made based on the customer’s requirement.

● Have Incomparable performance under a high load, low speed operation. Also perform well without lubrication;

● Excellent wear resistance in such places where an oil film is difficult to be formed due to reciprocating, oscillating motions and frequently intermittent operations;

● Remarkable resistance to corrosion and resistance to chemical attack;

● Maintenance free and save operating cost.

● All standard wear plates sizes are available.

● Special L shape, T shape or any other customized shape can be made based on customer requirement.

● Standadrd high tensile brass or Other material can be made based on your requirement.

| Type | 650 | 650S5 | 650W1 | 650W3 | 650S1 | 650S2 | 650S3 | |

| Material | CuZn25AI5Mn4Fe3 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 | ||||

| Density | 7.8 | 8.9 | 7.8 | 8.9 | ||||

| HB Hardness | ≥210 | ≥250 | ≥210 | ≥230 | ≥70 | ≥150 | ≥75 | |

| Tensile Strength MPa | ≥750 | ≥800 | ≥755 | ≥755 | ≥250 | ≥500 | ≥270 | |

| Yield Strength MPa | ≥450 | ≥450 | ≥400 | ≥400 | ≥90 | ≥260 | ≥150 | |

| Elongation % | ≥12 | ≥8 | ≥12 | ≥12 | ≥13 | ≥10 | ≥5 | |

| Thermal Expansion Coefficient | 1.9x10*%/°C | 1.8x10*9/°C | 1.6x10^*/°C | 1.8x10*/°C | ||||

| Max. Operation Temp. | -40~+250°C | -40~+400°C | ||||||

| Max. load MPa | 50 | 75 | 75 | 100 | 50 | |||

| Max. speed m/s | Dry | 0.5 | 0.1 | 0.5 | 0.1 | 0.5 | ||

| Lubricated | 1 | 0.25 | 1 | 0.25 | 2.5 | |||

| Max. PV (N/mm2*m/s) | Dry | 1.65 | 1 | |||||

| Lubricated | 3.25 | 1.65 | ||||||

| Lubricant | Feature | Typical Applications |

| SL1 Graphite + Additives |

Good Chemical resistance and low friction coefficients. Operation temperature up to +400oC |

Suitable for general industry applications exposed to atmosphere. |

| SL4 +MoS2+Additives |

Low friction coefficients and good water lubricating feature. Operation temperature up to +300oC |

Suitable for water lubrication condition. The applications include vessels, hydraulic turbines and steam turbines. |

ZCuZn25Al6Fe3Mn3 mechanical properties of brass ZCuZn25Al6Fe3Mn3 different zinc content, mechanical properties are also different pressure processing properties good plasticity, can withstand hot and cold processing

1 overview

2 Chemical composition

3. Pressure machining performance

4 Mechanical properties

5 Development History

6 Application Areas

![]()

Any alloy consisting of more than two elements is called special brass. Such as aluminum, lead, tin, manganese, nickel, iron, silicon composed of copper alloy, high-strength brass is one of them. High strength brass has strong wear resistance, high strength brass, high hardness, strong chemical corrosion resistance. And machining mechanical properties are also very superior. High-strength brass is often made to manufacture sheet, bar, bar, pipe, casting parts and so on.

The chemical formula of high-strength brass is ZCuZn25Al6Fe3Mn3, containing about 65% copper and about 24% zinc. Aluminum improves the strength, hardness and corrosion resistance of brass. There are three types of brasses at room temperature: brasses containing less than 35% zinc. The microstructure of brasses at room temperature consists of a single-phase solid solution, called brass.

Pressure machining performance editing

High force brass has good plasticity and can withstand cold and hot machining, but it is easy to appear medium temperature brittleness in forging and other hot machining. The specific temperature range varies with the different content of Zn, generally between 200 ~ 700℃. Therefore, the temperature during thermal processing should be higher than 700℃.

Mechanical properties editing

The mechanical properties of high-strength brass vary with zinc content. For brass, B and increase with the increase of zinc content. Therefore, the copper - zinc alloy containing more than 45% zinc has no practical value. HB > 200, compressive strength > 600MPa, elongation > 10%.

The term "brass" was first used in the Classic of Ancient Chinese Buddhism by Dongfangshuo in the Western Han Dynasty: "There is a palace in the northwest, with brass as the wall, and the palace of the Emperor." What kind of copper alloy this "brass" refers to remains to be seen. The book also has the titles of "bronze" and "brass", which refer to the color of ore and smelting products respectively, rather than copper-tin alloy and copper-zinc alloy. Kui of the Song Dynasty wrote "Da Ye Fu", and "it is brass, pit has various names, mountains are many simple", referring to pure copper refined by fire.

The word brass refers to copper and zinc alloy, which was started in the Ming Dynasty, and its record can be seen in the Ming Dynasty Canon: "Jiajing in the example, Tong Bao six million wen, a total of two fire brass 47,272 jin... ." Based on the analysis of the composition of the copper COINS in Ming Dynasty, it is found that the real brass of casting money mentioned in The Ming Dynasty Association Canon appeared much later than other copper alloys, because it is difficult to obtain the metal zinc in brass.

Zinc oxide can be quickly reduced to metallic zinc at 950℃ to 1000℃, while liquid zinc has been boiling at 906℃, so the reduced metallic zinc exists in the form of vapor. When the reaction is reversed on cooling, the vapor zinc is reoxidized from carbon dioxide in the furnace to zinc oxide, so special condensing devices are required to obtain the metal zinc. This is why the use of zinc was much later than that of copper, lead, tin, and iron, and one of the reasons for the late appearance of brass coinage.

However, at the Site of Yangshao culture in Jiangzhai, brass plates and tubes containing more than 20% zinc were unearthed, and two kinds of brass cones were also excavated from the longshan culture in Sanlihe county in Shandong Province. It is obvious that the appearance of these brass objects does not mean that the smelting technology of brass was mastered in prehistoric times, but that people acquired it by accident while using copper-zinc symbionts.

During the Shang and Zhou dynasties, the zinc content of copper ware was very low, generally in the order of 10-z. There were several copper and zinc sweet COINS in the western Han dynasty and Xinmang, among which the content of zinc in some COINS reached 7%, but this does not mean that the copper coin was produced in the Xinmang period of the Western Han Dynasty. Because these alloys are rare, the zinc content is generally much less than the 15 to 40 percent of the actual zinc content of brass. Therefore, we believe that these copper COINS containing zinc were produced during the han Dynasty when the copper and zinc symbionts were used. According to the investigation of the mines concerned, it is found that changwei, Yantai, Linyi and Hubei in Shandong province have copper-zinc co-sources rich in resources, which makes the smelted copper contain a small part of zinc. In tang Dynasty, due to the standardization of casting materials, the content of zinc in the cast COINS was constant.

Brass products remained popular in Europe for about 300 years, starting around 1230 AD, because they were much cheaper than large sculptures. Died in 1231

The statue of Archbishop Welp, in 1864, is the earliest known bronze statue made of brass. The process for casting brass products is as follows: the zinc ore and charcoal are first mixed with the copper block and heated to bind the zinc and copper tog. The alloy is then heated to melt, and the copper liquid is then poured into the mold. The earliest Bronzes in England were imported, mainly from Turne. The client may order from Tournay complete gravestones already mounted in beautiful soles or marble pedestals. The way to make a bronze gravestone is to first cast the statue, usually with a silhouette of a canopy around it, then place it on a slab of prefabricated stone and use a knife to carve out human details on the statue. Sometimes alabaster or other inlays were used for the hands and faces. When the statue was safely made, it was fastened to the stone base with a hidden pin in the lead bolt. The statue itself rests on a layer of asphalt. Large bronze statues were cast in sections and then joined tog.

![]()

Colliers brass application is very extensive, the casting made of bearing and bushing, domestic mainly made of high strength brass for matrix solid lubrication oil-free bearings (hereinafter referred to as solid embellish bearing), is to use brass Gao Ligao strength as matrix, and embedded radial arranged orderly cylindrical polymer filler for friction materials (general graphite, molybdenum disulfide, , such as oil lubricant), its superiority lies in its made of copper alloy and non-metallic antifriction material has the respective complementary advantages, not only has high bearing capacity, and break through the boundaries of generally depends on the oil film bearing grease lubrication, achieve no oil lubrication, The embedded solid lubrication is easy to form lubricating film, which plays a great role in improving its friction and wear performance, and is stable and reliable with high cost performance. Compared with the composite oil-free bearing, it has the advantages of good machinability, high precision, strong bearing capacity and good wear resistance. The self-lubricating guide bush guide can be used in many fields such as: engineering machinery joints, such as excavator, mining scraper, the rotating drill, concrete pump truck, rock drill machine, hoist, port cranes, etc., and metallurgical machinery casting machinery, water conservancy machinery, transportation machinery, rolling mill, bottle blowing machine blown film machine, injection molding machine cross-clamping differential, tire vulcanizer, trailer balance beam, vacuum switch, etc.