|

|

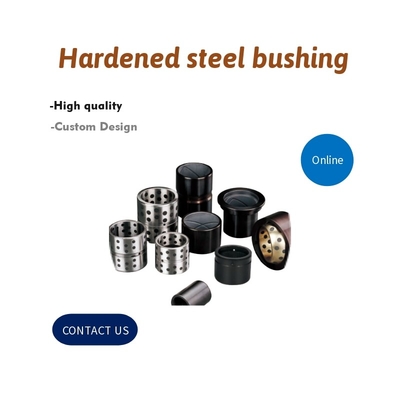

When it comes to precision machinery and equipment, hardened steel bushings play a crucial role in ensuring smooth and reliable operation. Among the various materials available, GCr15 and 45# steel are two of the most commonly used for hardened steel bushings, especially in metric sizes.

GCr15 steel, also known as bearing steel, is a high-carbon chromium bearing steel that offers excellent wear resistance, hardness, and toughness. It is widely used in the manufacturing of bearings, bushings, and other precision components due to its superior mechanical properties. When hardened and precision ground, GCr15 steel bushings provide a long-lasting and dependable solution for applications requiring high-speed rotation or heavy loads.

On the other hand, 45# steel is a medium-carbon steel that offers good strength and machinability. It is often used in the manufacturing of various mechanical parts, including bushings. While it may not have the same wear resistance as GCr15 steel, 45# steel bushings are still a cost-effective choice for many applications where the load and speed requirements are not as stringent.

When selecting hardened steel bushings in metric sizes, it is important to consider the specific requirements of your application. Factors such as load capacity, rotational speed, and operating environment will all affect the choice of material and design. Additionally, precision ground bushings offer tighter tolerances and better surface finishes, ensuring optimal performance and longevity.

Wh you are replacing worn-out bushings or designing a new system, GCr15 and 45# steel hardened steel bushings in metric sizes are reliable options that can meet your needs. With their superior mechanical properties and precision manufacturing, these bushings will provide smooth and reliable operation for your machinery and equipment.

Quality Hardened Steel Bushings manufacturers & exporter - buy Hardened Steel Bushings Material S45C -bearing tempered steel sleeve hardened steel sleeve bearing

Solid Bushing Hardened Steel Bushing Material S45C Self Lubricating Bearing

Find a Hardened Steel Bearings for your application, for hydraulic cylinders and pivot joints of excavator booms, arms and bucket joints.

Hardened steel bushings made of high quality low carbon steel or stainless steel with special technology. The surface can be cemented to improve hardness.

Hardened steel bushings are available in cylindrical, flanged and special configurations that are designed for a variety of applications, including earth moving equipment such as excavators and loaders; Drilling equipment; agricultural machines including harrows, plows and backhoes; Construction machines including grabs, buckets and grabs; and hydraulic cylinders, where they protect against wear from floors and eyes. Other applications include industrial washing machines, slide guides for industrial presses and components for suction pumps, machine tools and automatic machines.

With the advantages of low weight, low noise level and self-lubricating properties, VIIPLUS bearings are often used in the automotive industry.

Currently, over 50 sockets are used in every car. More and more traditional sintered bearings with needle bearings are being replaced by self-lubricating bearings. In addition to the bushings, the self-lubricating materials are applied to the other non-load-bearing parts such as the new resin-coated swash plate for the air conditioning and other components already developed by VIIPLUS.

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 35*45*30 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 40*48*35 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 40*50*45 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 40*50*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*55*44 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*55*55 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*56*46 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*62.2*42.2 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 50*60*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 50*60*60 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*70*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*70*60 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*70*80 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*72*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*75*40 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*80*35 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 65*80*63 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*85*70 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*85*74 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*85*85 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*85*91 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 75*90*79 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*70 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*120 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 85*100*67 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 85*100*84 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 90*105*92 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 100*115*74 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 100*115*95 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 100*115*120 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 100*115*131 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 110*125*124 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 110*130*123 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*70*40 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*80*85 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 71*86*85 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*100*67 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 40*50*40 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*55*35 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*55*40 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*55*49 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*55*60 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 45*60*35 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 50*60*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 50*60*59 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 50*60*70 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 50*65*47 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*65*40 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*65*49 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*65*60 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*65*74 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*70*42 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 55*70*54 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*70*80 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*75*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*75*59 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 60*75*65 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 65*80*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 65*80*55 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 65*80*74 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 65*80*90 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*80*79 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 70*85*78 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 71*86*75 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 75*92*60 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*90*90 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*50 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*66 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*78 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*80 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*85 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 80*95*90 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 90*105*96 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 100*115*105 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 110*130*85 |

| METRIC CYLIDRICAL BUSHINGS | STEEL BUSHING | 90*105*130 |

Sizes of hardened steel bushings with an inner diameter of 25 to 140 mm in various lengths. Suitable for excavators and other harsh environments with low wear resistance. Comes with internal and external grooves for oil lubrication.

In addition to the standard products shown in the catalog, non-standard products can be offered or ordered upon request.

-Hardened steel - S45C

·Hardened steel bearings offer increased wear resistance, while the interior remains ductile and crack resistant

·Suitable for heavy equipment, hydraulic damping and rotational applications

·Special alloy contains manganese and vanadium for greater strength and toughness, higher hardening rate and greater wear resistance

Industrial

Earth moving machines, excavators, drilling machines, agricultural machines, various equipment buckets, buckets, pliers, hydraulic cylinder

·Steel bushings, ideally suited for lubricated applications

· With smooth or grooved sliding layer

· Suitable for grease lubrication

·Low speed at high specific pressure

· Bearing shapes available in standard dimensions: Smooth cylindrical bushings

· Customized bearing shapes: Bearings with multiple lubrication grooves, non-standard parts

| Max. load | Static | 250N/mm² | |

| Dynamic | 100N/mm² | ||

| Max.speed | Lubricated | 10m/s | |

| Max. PV | Lubricated | 1.5N/mm²*m/s | |

| Density | 7.8g/cm³ | ||

| Hardness | HRC≥40 | ||

| Coefficient of thermal expansion | 1.1x10-5℃ | ||

| Friction coefficient | Lubricated | 0.1-0.25 | |

| Operation Temperature range | -40°C~+120°C | ||

| Alloy Bonding Strength | Roughness | Ra<0.8 | |

| Hardness | HRC 58-62 | ||

| Grease lubricating recommended for every 8 hours | |||

| Static | 250N/mm² | ||

| Dynamic | 100N/mm² | ||

| Max.speed | Lubricated | 10m/s | |

| Max. PV | Lubricated | 1.5N/mm²*m/s | |

MATING HOUSING : H7

MATING SHAFT : E7 / F7

| OPERATING PERFORMANCE | |||

| Dry | Poor | ||

| Oil lubricated | Good | ||

| Grease lubricated | Very Good | ||

| Water lubricated | Not recommended | ||

| Process fluid lubricated | Depending on fluid |

||

Typical applications of this material include harbor machinery, forestry machinery, civil engineering machinery, truck axles and handling machinery as well as the rod eyelets of hydraulic cylinders and connection bearings.

Hardened Steel Bushing are available in cylindrical, flanged and special configurations designed for a wide range of applications, including earth moving, such as excavators and loaders; drilling equipment; agricultural machinery, including harrows, plows and excavators; construction equipment including grippers, spoons and grippers; and hydraulic cylinders in which they protect against wear of pants and eyelets. Other applications include industrial washing machines, sliding guides for industrial presses, and components for suction pumps, machine tools and automatics.

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the gleitlagerbuchsen products for you once every two days, until you get the gleitlagerbuchsen products.

When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

WE ARE A PROFESSIONAL

SELF-LUBRICATING BEARING MANUFACTURER & SUPPLIER

![]()

If you have any questions, please feel free to contact us,you are always welcome, thank you!