|

|

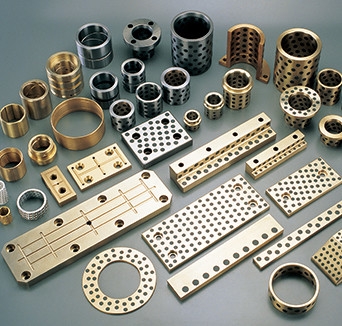

| Brand Name: | bushing |

| Model Number: | Solid bushing, Phosphor Bronze Bearings |

| MOQ: | NEGOTIABLE |

| Price: | Price Graphite Bushing Parts Factory Price |

| Payment Terms: | TT IN ADVANCE |

| Supply Ability: | Bronze Bushings Online • Sliding Bearings Manufacturers • Self-lubricating Bushing Suppliers |

ASTM B505 C83600 bronze oilless bearings are specifically designed for use in pump parts and valve bodies, offering exceptional performance and durability in various industrial applications. This bronze alloy, also known as C83600, exhibits superior mechanical properties, corrosion resistance, and wear resistance, making it an ideal material for bearings that require lubrication-free operation.

The oilless bearings, made from ASTM B505 C83600 bronze, eliminate the need for regular lubrication, reducing maintenance requirements and operational costs. They are able to operate smoothly and reliably even in harsh environments with high temperatures, pressures, and corrosive media.

In pump parts, these bearings provide stable and efficient rotation, ensuring the smooth flow of fluids and gases. For valve bodies, the bearings offer precise control and durability, ensuring reliable performance and long service life.

The use of ASTM B505 C83600 bronze oilless bearings in pump parts and valve bodies not only enhances the overall performance of the equipment but also contributes to energy efficiency and environmental sustainability. Their robust design and material properties make them a cost-effective solution for a wide range of industrial applications.

This kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection molding machines

![]()

CuSn5ZnPb5-C Bronze Graphite Plugged Bushings Cast Bronze Bearings Material

| % min | % máx | |

|---|---|---|

| Cu | 84.0 | 86.0 |

| Pb | 4.0 | 6.0 |

| Sn | 4.0 | 6.0 |

| Zn | 4.0 | 6.0 |

| Fe | 0.30 | |

| Ni | 1.0 | |

| Al | 0.005 | |

| Sb | 0.25 | |

| S | 0.08 | |

| P | 0.05 | |

| Si | 0.005 |

| Bearings | Corrosion Resistance | Corrosion Resistance |

| Bearings | Friction & Wear Properties | Wear Resistance |

| Bearings | Machining Properties | Machinability, Good |

| Bearings | Mechanical Properties | Moderate Strength |

| Bushings | Corrosion Resistance | Corrosion Resistance |

| Bushings | Friction & Wear Properties | Wear Resistance |

| Bushings | Mechanical Properties | Moderate Strength |

ZCuZn25Al6Fe3Mn3 Brass Bearing Graphite,HBsC4C Cast Brass Bush,C86300 plugged Oiles Bushing.

| Material | CuZn25Al5 | CuSn5Pb5Zn5 | CuAl10Ni5Fe5 | CuSn12 | CuZn32Al5Ni3 |

| Density | 8 | 8.9 | 7.8 | 8.9 | 8 |

| HB hardness | >210 | >70 | >150 | >95 | >280 |

| Tensile strength N/mm2 | >750 | >200 | >600 | >260 | >540 |

| Yeild strength N/mm2 | >450 | >90 | >260 | >150 | >450 |

| Elongation % | >12 | >15 | >10 | >8 | >0.3 |

| Coefficient of linear expansion |

1.9x10-5/°C | 1.8x10-5/°C | 1.6x10-5/°C | 1.8x10-5/°C | 1.8x10-5/°C |

| Max. temp. | -40~+300 | -40~+400 | -40~+400 | -40~+400 | -40~+150 |

| Max. load N/mm2 | 100 | 60 | 50 | 70 | 150 |

| Max. speed (Dry) m/min | 15 | 10 | 20 | 10 | 15 |

| Max. PV N/mm2*m/min (Lubrication) |

200 | 60 | 60 | 80 | 200 |

| Compression deformation 300N/mm2 |

<0.01mm | <0.05mm | <0.04mm | <0.05mm | <0.005mm |

![]()

Advantages

1.One stop service ( no more difficulties orders from China directly).

2.Over 10 years experience, solving all problem advanced save time and cost.

3.Best price based on our smart solution and supply chains management.

4.Strict quality control through our QC team.

5.Share with ideas for marketing products and consulting for production.

6.Good work team to win the market in your country, can be good sourcing agent in China.

7.Big discount for shipping based on our large export.

![]()