|

|

| Brand Name: | bronzelube.com |

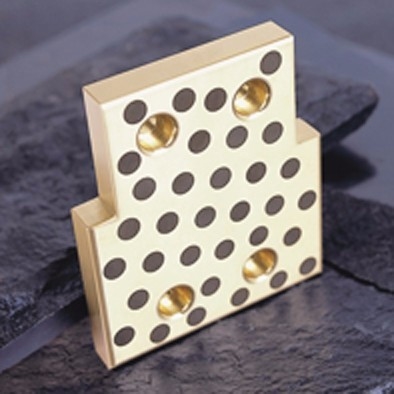

| Model Number: | Straight Bushing:Bronze with Embedded Solid Lubricant Material,Lead Free |

| MOQ: | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price: | US$0.11 - US$21.11 / Pieces,NEGOTIABLE |

| Payment Terms: | TT IN ADVANCE,L/C,Western Union |

| Supply Ability: | Self Lube Bearing Manufacturing Dimensions Tolerance Assembly |

When it comes to the precision and durability requirements of robotic systems, lubrication-free components play a crucial role. Among these, solid bronze bushings with graphite lubrication, specifically those made of C86300 bronze alloy, offer a unique combination of strength, wear resistance, and self-lubricating properties.

The solid bronze sleeve lube guide, also known as an oilless bushing, is designed to provide a maintenance-free solution for robotic applications. The C86300 bronze alloy, which is a high-tin bronze alloy, exhibits excellent corrosion resistance and wear properties, making it ideal for use in demanding environments.

The graphite lubrication incorporated into the bushing provides a continuous and effective lubricating film between the moving surfaces, reducing friction and wear. This eliminates the need for periodic lubrication, simplifying maintenance and reducing downtime.

The inch-sized dimensions of these bushings allow for easy integration into existing robotic systems. Whether it's for precision positioning, heavy-duty lifting, or any other robotic application, the solid bronze sleeve lube guide with graphite bushing offers a reliable and long-lasting solution.

In summary, the oilless, solid bronze C86300 graphite bushing is an excellent choice for robotic applications requiring precision, durability, and low maintenance.

VIIPLUS established itself as an industry leader in self-lubricating bearings exported from China.The U.S. 's , oilless and DAIDO are the world's top three makers of self-lubricated bearings, with strong positions in aerospace, automotive and transportation.

| Chemical Requirements | ||||||||||||

| Copper Alloy UNS No. |

Composition, % max, except as indicated | |||||||||||

| Nickel | ||||||||||||

| Copper | Tin | Lead | Zinc | Iron | Including | Aluminum | Manganese | Antimony | Sulfur | Phosphorus | Silicon | |

| Cobalt | ||||||||||||

| C86300 | 60.0–66.0 | 0.20 | 0.20 | 22.0–28.0 | 2.0–4.0 | 1.0A | 5.0–7.5 | 2.5–5.0 | ... | ... | ... | ... |

| C90500 | 86.0–89.0 | 9.0–11.0 | 0.30 | 1.0–3.0 | 0.20 | 1.0A | 0.005 | ... | 0.20 | 0.05 | 0.05B | 0.005 |

| C91100 | 82.0–85.0 | 15.0–17.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C91300 | 79.0–82.0 | 18.0–20.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C93700 | 78.0–82.0 | 9.0–11.0 | 8.0–11.0 | 0.8 | 0.7C | 0.50A | 0.005 | ... | 0.50 | 0.08 | 0.10B | 0.005 |

| A In determining copper minimum, copper may be calculated as copper plus nickel. | ||||||||||||

| B For continuous castings, phosphorus shall be 1.5 % max. | ||||||||||||

| C Iron shall be 0.35 % max. when used for steel-backed. | ||||||||||||

With the rapid process of industrialization in China, the application of industrial robots in industry is becoming more and more popular. Sliding Bearing & Bushings,the main part of industrial robot, has been paid more and more attention.

Robotics is especially important because the possibilities for applications are nearly endless; as a result, robots have become far more commonplace in many different industries over the years. Viiplus offer quality precision bushings products for robot.

![]()

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Product NO. |

Chemical Compositions |

||||||||

VSB-50 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

![]()

START YOUR

PROJECTWITH AN APPLICATION ENGINEER