|

|

| Brand Name: | bushing |

| Model Number: | Die Setting Components |

| MOQ: | 100 Piece/Pieces (Min. Order) |

| Price: | Price Graphite Bushing Parts, (SAE 660) Leaded Tin Bronze Bearings,863 (SAE 430B) 862 (SAE 430A)Manganese Bronze |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | Bronze Bushings Online • Sliding Bearings Manufacturers • Self-lubricating Bushing Suppliers |

The die guide bushing, in its universal straight type configuration, is a crucial component in various machinery and tooling applications. This type of bushing is designed to provide precision guidance and stability, enabling accurate alignment and smooth operation.

The bushing itself, without a bolt hole, offers flexibility in installation and can be used in a wide range of applications. The washer, which accompanies the bushing, also plays a vital role in ensuring the stability and smooth functioning of the system.

Both the bushing and washer are precision-manufactured from high-quality materials that are chosen for their durability, strength, and corrosion resistance. This ensures that the components can withstand the rigorous demands of heavy-duty industrial applications.

The universal straight design of the bushing allows for easy installation and adjustment, making it a versatile choice for various machine tool setups. The washer, without a bolt hole, provides additional support and stability, ensuring that the bushing remains securely in place during operation.

Overall, the die guide bushing, in its universal straight type configuration, along with the accompanying washer without a bolt hole, offers a reliable and dependable solution for precision guidance and stability in various industrial applications.

Die guide sleeve is also known as a high-strength copper substrate (die guide sleeve, high-strength brass bearing). Graphite or high performance solid lubricated molybdenum disulfide solid lubricant products. It breaks through the limitations of general bearing film lubrication. During use, heat of friction causes solid lubrication and shaft friction, forming excellent conditions for powder and oil lubrication, protective shaft wear, and eternal solid lubrication characteristics. It is twice as high as the usual copper sleeve and twice as resistant to wear.

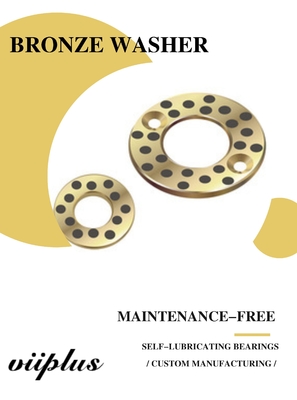

Washer, self-lubricating, "SOBW" Series Washer, self-lubricating,

Price and delivery time on request.

"SOBW" Brass Washer, self-lubricating bearing parts

Maintenance-free bearing and guide bushes, bronze with solid lubricant

Custom-made washer products

Find bronze brass parts washer products faster and inquire online!

Properties: "SOBW" bronze brass washer

| Base Material: | Special Brass (SO#50SP2) |

| Self-lubricating: | Yes |

| Lubricant: | Graphite |

| Surface Pressure P: | 100 N/mm² |

| Sliding speed v: | 30 m/min |

| P*v-value: | 200 N/mm² x m/min |

| Operating temperature: | -50°C / +200°C (max. 300°C) |

| Friction coefficient: | 0,07 |

Our Bronze Thrust Washers are available in (3) types: Plain Thrust Washer, Graphite Plugged Thrust Washer and Oil / Grease Grooved Thrust Washer.

Thrust washers can be found in almost every appliance, machine, transportation conveyance, power tool, and recreational device that has moving parts, axles, bolts, pins, bearings, and rotating components. In their simplest form, thrust washers are long-wearing flat bearings in the shape of a washer that transmit and resolve axial forces in rotating mechanisms to keep components aligned along a shaft. Thrust washers are an economical alternative to rolling thrust bearings whenever forces velocities are moderate.

They are manufactured from a variety of Bronze Alloys, including: C95400 Aluminum Bronze, C93200 Bearing Bronze and C86300 Manganese Bronze. We provide your desired Thrust Washers according to the specifications you require.

Die Guide Bushing Universal Straight Type Components Guide Bushing. Material: Bronze with Graphite, machining tolerance H7

recommended hole f7: High precision e7 general use light load d8 high load mating post tolerance, bronze washer type without bolt holes.

Guide Bushing Flange Type

The bronze graphite sleeve bushing & bearings are used for labor-saving in various production lines. Products of VIIPLUS Oilless Industry are developing the world standard. In addition to standard product series, tailor-made products to customers' requirements are available.

Standard Components for Press Die

Standard Components for Plastic Moulds

Standard Components for Sliding Material

Standard part for the main Die Setting components as follows

Die Setting Components

Die Guide Components

Slide Components

Cam Slide Components

Blanking Die Components

Die Materials

Cam Units

NAAMS Standard

European Standard

Standard Components for Plastic Moulds

Standard Components for Plastic Moulds

For the sliding parts of current plastic molding, steel hardened products are mainly used. This is a concern of complicated mold structure and environmental pollution due to the use of grease. VIIPLUS CHINA standard parts for plastic molds can eliminate oil from all sliding parts in the molds. In addition to standard product series, made products to customers' requirements are available.

part for the main Standard Components for Plastic Molds.