|

|

| Brand Name: | VIIPLUS |

| Model Number: | Graphite Bronze Bearings |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

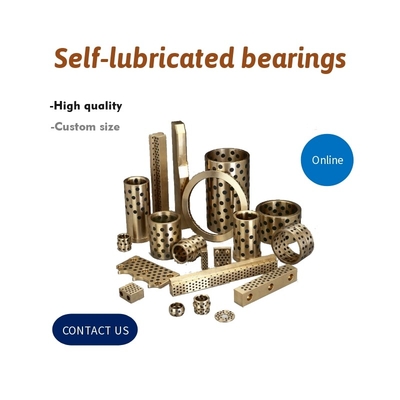

| Supply Ability: | plug graphite bearings, China, manufacturers, suppliers, factory, wholesale, Metal Journal Bearing, DU Self Lubricating Bearing, Composite Thrust Bearing, Composite Self Lubricating Bushings, Graphite Alloy Bearing, Flange Cast Iron Bearing |

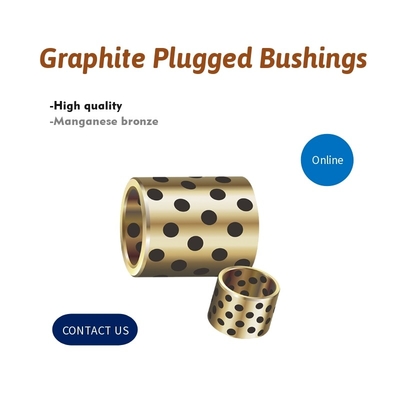

Self-lubricating graphite plugged oilless brass bushings are precision-engineered components that offer exceptional wear resistance and self-lubricating properties without the need for external lubrication. These bushings are commonly used in a wide range of industrial applications, particularly those involving rotating or sliding movements.

The key feature of these bushings is the graphite plugs that are evenly distributed throughout the brass matrix. Graphite is a natural lubricant that provides a continuous source of lubrication as the bushing wears. This ensures smooth operation and reduces friction, wear, and maintenance requirements.

The brass material itself offers excellent strength, durability, and corrosion resistance. It is able to withstand high loads and temperatures, making it suitable for demanding applications. The combination of brass and graphite creates a bushing that is both strong and self-lubricating.

The oilless design of these bushings eliminates the need for regular lubrication, reducing downtime and maintenance costs. This is especially beneficial in applications where lubrication may be difficult or undesirable, such as in dusty or dirty environments.

Self-lubricating graphite plugged oilless brass bushings are also known for their precision fit and dimensional stability. They are carefully manufactured to ensure tight tolerances and consistent performance. This allows for smooth operation and reliable performance in critical applications.

In summary, self-lubricating graphite plugged oilless brass bushings offer exceptional wear resistance, self-lubricating properties, strength, and durability. They are suitable for a wide range of industrial applications and can significantly reduce maintenance requirements and operating costs.

All graphite plugged oilless bushings are self-lubricating and maintenance-free. These bushings are made of continuously cast bronze and plugged with grease plugs. The bushing and its mating surface should always be separated by a layer of grease.

The high-strength copper alloy provides the mechanical load-carrying capacity of the graphite plugged oilless bushing, and the lubricant can provide a continuous source of lubrication for the bearing surface to form a better friction pair; it is suitable for medium and high load, frequent start-up, and it is difficult to form an oil film.

Typical applications include: plastic machinery toggle bearings, Green column guide bushes, port machinery, hydraulic engineering gates, mining equipment, etc.

1. Total Self-Lubricating: No oil or grease required![]()

The self-lubricating properties allow the use of bearings where lubrication is difficult, expensive to manufacture and where grease / oil cannot be used. Excellent lubrication is achieved even under heavy loads at low speeds.

2. Excellent Wear Resistance:

Excellent wear resistance is achieved under severe operating conditions such as heavy loads, low speed, reciprocating, oscillating and intermittent motion where film formation is difficult.

3. Low Coefficient of Friction: 0.04 to 0.2 typical:

Self-lubrication with specially embedded solid lubricants reduces friction.

4. Wide Operating Temperature Ranges: -415° ° to 1,100° °F

Superior performance is exhibited under high and low temperature conditions.

5. Corrosion and Chemical Resistance:

Performance is not affected by water and caustic chemicals.

6. Designed to Exceed Your Requirements:

High precision products with close tolerances.

7. Cost Competitive:

Reduced maintenance, replacement and downtime cost of the final item due to its exceptional service life compared to similar self-lubricating products.

Self Lubricating Graphite Plugged Oilless Bushings are customer-specified products. By impregnating graphite in certain designed pattern into working surface of the bearing, the product can operate in dry conditions through the mechanism of solid lubrication. Self Lubricating Graphite Plugged Oilless Bushings can be used in high temperature environments, such as hot steam rolling equipment, paper making machineries, etc.

| Basic material | CuZn25A16Fe3Mn3 | Dynanic load | 120N/mm² |

| Base hardness | HB210~275 | Friction Coef | <0.16 |

| Temperature Max | 300℃ | Speed limit | dry 0.4m/s oil 5m/s |

Custom Made Parts| One Pc, 2 Pc, Half Bearings, Flanged Units, Wear Plates, Strips, Liners, Thrust Washers, Special Size

Custom Made Parts| One pc, 2 pc, Half bearings, Flanged units, Wear plates, Strips, Liners, Thrust Washers, Special Sizes and Shapes-Imperial line bushings (dimensions in inches)

Custom Design Self Lubricating Parts

Recognizing that these are essentially conventional components, to which lubricant in the form of graphite is added, helps the mold maker to realize their significant advantages.

Graphite bronze bearings are made of continuous cast bronze bars. They are then milled and capped with graphite caps of solid lubricant. Connected graphite bushings are perfect for applications where maintenance is difficult and where normal greases and oil-based lubricants can burn due to high temperatures. The cast bronze base material offers these graphite bronze bearings a greater bearing capacity than other self-lubricating bronze bushings.

Graphite bronze bearings are a substrate of carbon steel, bronze powder, , fiber and other materials through a special process to produce self-lubricating graphite bronze bearings products, with the characteristics of environmental protection.

Solid Bronze bushings and plates are made entirely of tin copper, CuSn10P, which has a very good machine capacity. All surfaces of solid bronze bushings are machined.

Solid iron bushings and sheets are manufactured in the same way as bronze material, but are much lower costs if you do not have high performance requirements.

|

REPLACEMENT OILES 500SP1-SL1 SERIES Self Lubricating Parts Thrust Washer |

I.D.: Φd | O.D.: ΦD | Thickness: T | Position of Mounting hole: P.C.D | Number of Hole | Countersunk Screw |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-0603 | 6.2 | 25 | 3 | 15 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-0803 | 8.2 | 28 | 3 | 18 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1003 | 10.2 | 30 | 3 | 20 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1203 | 12.2 | 40 | 3 | 28 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1203N | 12.2 | 40 | 3 | - | - | - |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1303 | 13.2 | 40 | 3 | 28 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1403 | 14.2 | 40 | 3 | 28 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1503 | 15.2 | 50 | 3 | 35 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1603 | 16.2 | 50 | 3 | 35 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1603N | 16.2 | 50 | 3 | - | - | - |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-1803 | 18.2 | 50 | 3 | 35 | 2 | M3 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-2005 | 20.2 | 50 | 5 | 35 | 2 | M5 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-2505 | 25.2 | 55 | 5 | 40 | 2 | M5 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-2505N | 25.2 | 55 | 5 | - | - | - |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-3005 | 30.2 | 60 | 5 | 45 | 2 | M5 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-3005N | 30.2 | 60 | 5 | - | - | - |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-3505 | 35.2 | 70 | 5 | 50 | 2 | M5 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-4007 | 40.2 | 80 | 7 | 60 | 2 | M6 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-4507 | 45.2 | 90 | 7 | 70 | 2 | M6 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-5008 | 50.3 | 100 | 8 | 75 | 4 | M6 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-5508 | 55.3 | 110 | 8 | 85 | 4 | M6 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-6008 | 60.3 | 120 | 8 | 90 | 4 | M8 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-6508 | 65.3 | 125 | 8 | 95 | 4 | M8 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-7010 | 70.3 | 130 | 10 | 100 | 4 | M8 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-7510 | 75.3 | 140 | 10 | 110 | 4 | M8 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-8010 | 80.3 | 150 | 10 | 120 | 4 | M8 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-9010 | 90.5 | 170 | 10 | 140 | 4 | M10 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-10010 | 100.5 | 190 | 10 | 160 | 4 | M10 |

| graphite bronze bushing Self Lubricating Parts Thrust Washer-12010 | 120.5 | 200 | 10 | 175 | 4 | M10 |

1.no oil supply device, oil hole, oil groove

The cost of the fuel supply system, the cost of processing, assembling, and so on, can greatly reduce the cost of manufacturing.

2.Operation cost reduction

Greatly reduce the use of lubricating oil and equipment maintenance costs, but also exempt from the risk caused by the shortage of oil.

3.design time shortened

No oil can make the design, structure is greatly simplified, reduce costs, save design time. In addition, using self-lubricating bearings can also improve the mechanical properties and prolong get remarkable results using life and improve the reliability.

4.recovery and environmental protection of lubricant

No need to waste oil recycling, is conducive to environmental protection.

The main function of a self-lubricating mold component is to guide and control movement.

This mold is usually made of aluminum bronze, an excellent carrier material, with integrated graphite plugs. The adapted part of the mold (guide) is usually made of hardened steel. When the two parts move relative to each other, very slippery graphite sheets with a thickness of one atom exfoliate and break down on the wearing surface. With each cycle, a little more graphite breaks, so the process is constantly replenished. Graphite does not evaporate and is relatively inert, so the lubrication it provides is almost constant.

1.In the possible case, the design uses the standard specification as far as possible;

2.Please note that there is no foreign body in the assembly;

3.After using the sliding surface, formed by solid lubricant oil film in surface with black or gray black phenomenon, please do not scrub, as usual.

4.Before the assembly, if the lubricating oil applied to the grinding parts, can shorten the running in period, conducive to the operation of machinery, operation;

5.When the assembly should be slowly pressed into, it is strictly forbidden to beat, so as to avoid damage to the bearing and deformation;

6.Design, different parts should be selected with appropriate material, in order to improve the mechanical performance, to extend the service life of the bearing;

7.In the high load, reciprocating motion, the proposed use of screw fixation;

8.In fresh water, sea water and in the sea, on the use of stainless steel or surface plating.

1. Flexible, simple, convenient design with wide applications

2. FunctionaI in absence of oiI

3. Cost efficiency

4. Excellent performance under high load and low speed circumstances

5. In circumstances where it is difficult to generate hi-films, such as reciprocating movements, rotating movements and frequent on-off, Graphite Bronze Bearings highlights its excellent abrasion resistance.

6. Excellent chemical resistance and corrosion resistance

| Service range | ||

|---|---|---|

| Lubrication conditions | Dry | Periodic lubrication |

| Service temperature range (℃) |

-40~+300 | -40~+150 |

| allowable max. contact pressure : P (N/mm2) |

29 | 29 |

| allowable max. velocity : V (m/s) |

0.50 | 1.00 |

| Allowable max. PV value (N/mm2・m/s) |

1.65 | 3.25 |

1.Construction machinery

2.Transport equipment

3.Pulp and papermaking machinery

4.Off-shore equipment

All kinds of sliding elements can be supplied or produced on request.

Such as:Custom Thrust Washers , Custom Sleeve Bearings, Custom Flange Bushing, Cutom Shoulder Bushing, Custom Sleeve Bearing, Custom V-Channel,Half Bearings, Flanged Units, Wear Plates, Strips, Liners, Self-lubricating parts...

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the gleitlagerbuchsen graphite bronze bearings products for you once every two days, until you get the gleitlagerbuchsen graphite bronze bearings products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

WE ARE A PROFESSIONAL

SELF-LUBRICATING BEARING MANUFACTURER & SUPPLIER

![]()

All graphite plugged oilless bushings are self-lubricating and maintenance-free. These bushings are made of continuously cast bronze and plugged with grease plugs. The bushing and its mating surface should always be separated by a layer of grease.