|

|

| Brand Name: | BRAND CHINA REPLACMENT OILES 500 GUIDE BUSHINGS |

| Model Number: | Bronze Graphite plug Bushings met the tolerances |

| MOQ: | 300 Piece/Pieces (Min. Order) |

| Price: | $0.10 - $3.00 / Pieces |

| Payment Terms: | TT IN ADVANCE,L/C,Western Union |

| Supply Ability: | plug graphite bearings, China, manufacturers, suppliers, factory, wholesale, Metal Journal Bearing, DU Self Lubricating Bearing, Composite Thrust Bearing, Composite Self Lubricating Bushings, Graphite Alloy Bearing, Flange Cast Iron Bearing |

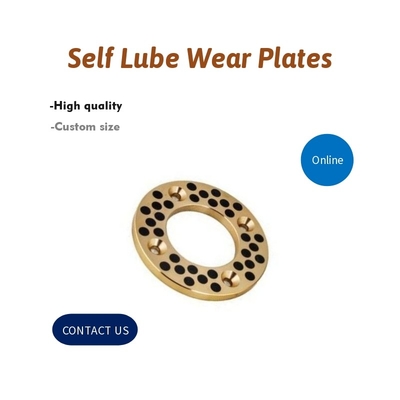

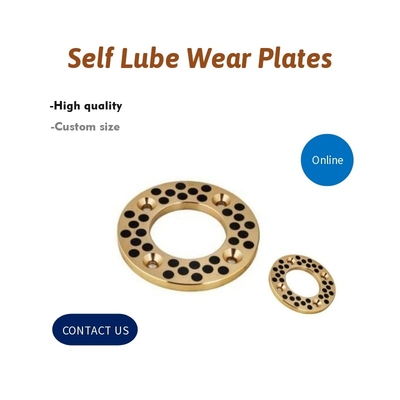

The Bronze Thrust Bearing 954 Bronze with Graphite Plugs is a highly specialized component designed to provide superior wear resistance and durability in thrust bearing applications. The combination of 954 bronze and graphite plugs offers a unique blend of properties that ensure smooth and reliable operation.

The 954 bronze, often referred to as tin-based bronze, is chosen for its excellent strength, corrosion resistance, and thermal conductivity. This material is well-suited for demanding applications that require a bearing material that can withstand high loads and temperatures.

The graphite plugs, evenly distributed within the bronze matrix, provide a continuous source of lubrication. Graphite is a natural lubricant that reduces friction and wear, ensuring smooth operation of the thrust bearing. The plugs act as reservoirs of graphite lubricant, releasing it as needed to maintain the desired level of lubrication.

The incorporation of graphite plugs into the 954 bronze matrix results in a thrust bearing that is both strong and self-lubricating. This eliminates the need for external lubrication, reducing maintenance requirements and downtime. The self-lubricating properties also ensure consistent performance and longer bearing life.

The Bronze Thrust Bearing 954 Bronze with Graphite Plugs is suitable for a wide range of industrial applications, including heavy machinery, presses, punches, and other equipment that involves thrust loads. It is particularly well-suited for applications where lubrication may be difficult or undesirable due to dust, dirt, or other contaminants.

In summary, the Bronze Thrust Bearing 954 Bronze with Graphite Plugs offers superior wear resistance, durability, and self-lubricating properties. It is an excellent choice for thrust bearing applications that require a reliable and long-lasting bearing solution.

Replace OILES #500 SPW Oilless Thrust Washer with Graphite Plugs Material Bronze alloy CuZn25Al5Mn4Fe3 + Graphite plugs.

The oilless bronze thrust washer were developed for high load, low speed applications and are manufactured from high strength rotational molded bronze using a specially formed graphite plug as a lubricant.

Our oilless bronze thrust washers are available in metric and imperial sizes. Our in-house machining service can produce non-standard sizes to suit specific customer requirements.

1. Heavy duty tractor and farm implement equipment

2. Mining equipment

3. Forestry equipment

4. Mixing tank bladeshaft support

5. Foundry, furnace and steel production equipment

6. HVAC applications

7. Heavy duty caster and wheel support bearings

8. Kiln kart veneer dryer applications, and possiblely other applications

PODKŁADKA ŚLIZGOWA SOBW , SOBW- maintenance-free - sliding washer is made of very hard bronze (base material) and specially placed solid grease (graphite).

Set the graphite to match the direction of travel.

The base material bears the load, and the solid grease ensures the lubrication of the bearing throughout its service life.

The graphite composition must be able to lubricate the sliding surface of bronze.As the bearing rotates, the grease film diffuses to brown.

This means that there is always a gap between the two sliding surfaces in order for the bronze and graphite to work effectively.

Recommended maximum operating temperature: 300°C (bearing manufactured at 1000°C) greater clearance shall be provided to compensate for thermal expansion at operating temperatures above 100°C.

![]()

| Standard No | d | D | T | 0 | Bolt | |||

| -0.1 | D1 | Q'ty | size | d1 | ||||

| SPW-10 | 10.2 | 40 | 3 | .... | ..... | .... | .... | |

| SPW-12 | 12.2 | 40 | 28 | 2 | M3 | 3.5 | ||

| SPW-13 | 13.2 | |||||||

| SPW-14 | 14.2 | |||||||

| SPW-15 | 15.2 | 50 | 35 | |||||

| SPW-16 | 16.2 | |||||||

| SPW-16N | .... | .... | .... | .... | ||||

| SPW-18 | 18.2 | 35 | 2 | M3 | 3.5 | |||

| SPW-20 | 20.2 | 5 | M5 | 6 | ||||

| SPW-20N | .... | .... | .... | .... | ||||

| SPW-25 | 25.2 | 55 | 40 | 2 | M5 | 6 | ||

| SPW-25N | .... | .... | .... | .... | ||||

| SPW-30 | 30.2 | 60 | 45 | 2 | M5 | 6 | ||

| SPW-35 | 35.2 | 70 | 50 | |||||

| SPW-40 | 40.2 | 80 | 7 | 60 | M6 | 7 | ||

| SPW-45 | 45.3 | 90 | 67.5 | |||||

| SPW-50 | 50.3 | 100 | 8 | 75 | 4 | |||

| SPW-55 | 55.3 | 110 | 85 | |||||

| SPW-60 | 60.3 | 120 | 90 | M8 | 9 | |||

| SPW-65 | 65.3 | 125 | 95 | |||||

| SPW-70 | 70.3 | 130 | 10 | 100 | ||||

| SPW-75 | 75.3 | 140 | 110 | |||||

| SPW-80 | 80.3 | 150 | 120 | |||||

| SPW-90 | 90.5 | 170 | 140 | M10 | 11 | |||

| SPW-100 | 100.5 | 190 | 160 | |||||

| SPW-120 | 120.5 | 200 |

175 |

|||||

Bronze Thrust Bearing enhance the hardness of high hardness brass, giving rise to higher load bearing capacity and better wear-resistant property. The products are widely used in continuous casting rolling machine, mining equipment, engineering equipment, injection-molding machines, etc. Because of its high hardness, it's difficult to machining and finish, it's recommended only for really high load applications.

|

Basic material |

CuZn25A16Fe3Mn3 |

Dynanic load |

120N/mm² |

|

Base hardness |

HB210~275 |

Friction Coef |

<0.16 |

|

Temperature Max |

300℃ |

Speed limit |

dry 0.4m/s oil 5m/s |

Necessary maintenance usually involves checking consumption every six months to two years, depending on usage time and load.It is recommended that the parts be re-lubricated each time they are removed.Do not remove the existing solid grease layer.Continuous lubrication is not required, as the part does not require maintenance if all requirements for the use of bronze with solid grease are complied with.Machining: bronze is easy to process.

Basically, there is not much difference between our products and ordinary steel processing.No special tools are required, but remember to use sharp tools, preferably new ones.

It is recommended to use the grease for HSS or carbide tools.As with ordinary steel, the distance of the machine is about 0.3 mm during rough milling.When milling/roughing, use low feed rate and low cutting depth.Operating temperature: -50°C / + 200°C (Max. 300°C)

Jdb-1 is a universal basic product, regardless of high pressure, low pressure, high temperature, low temperature, oil lubrication, oil free lubrication or water lubrication.They all apply.

The matrix of the product is high-strength brass, which is twice as hard as the general copper cover.Wear resistance increased more than twice.

Therefore, the continuous casting machine, rolling mill, conveyor in the metallurgical industry can be used.Also used for plastic injection molding machine locking mechanism, extrusion mechanism.Automatic switch of high voltage, lifting support of construction machinery, and arc door support of water conservancy project.Pulley and drive wheel parts.There are also paper dryer, automobile mold, ship anchor sliding parts and so on.

JDB 1 2 is mainly suitable for low load, high temperature and medium speed applications, such as fireplace door hinges, oven raceway, light industrial machinery, machine tool industry, etc.

The internal material of jdb-3 is the same as that of jdb-2. In addition to the function of jdb-2, it also reflects the functions of saving cost, improving compressive strength and welding and installation of end face and matrix.

It is suitable for non-oil lubricating parts in construction machinery, metallurgical machinery and conveying machinery.

Jdb-4 is a typical material - saving product where mechanical properties are not required.It can be used as a substitute material for jdb-2.Can greatly reduce the cost, to meet the use of requirements, such as: mold guide sleeve, injection molding machine mold frame.

Jdb-5 is an enhanced product.It has very high compressive performance, especially suitable for supporting parts of the crane, such as excavator support, winch support, crane support, etc.But because the matrix is steel.So should not be used in water or acid, alkali occasion.

|

code |

JDB-1 |

JDB-2 |

JDB-3 |

JDB-4 |

JDB-5 |

||

|---|---|---|---|---|---|---|---|

|

|

ZCuZn25 |

ZCuSn6Zn6Pb3 |

ZCuAI10Fe3 |

ZCuSu10P1 |

ZCuSn6Zn6Pb3 |

HT250 |

GCr15 |

|

|

GCuZn25 |

GCuSn6Zn6Pb3 |

GCuAI10Fe3 |

- |

CuSn6Zn6Pb3 |

- |

B1 |

|

|

G-CuZn25 |

GB-CuSn5Zn5Pb5 |

GB-CuAI10Ni |

GB-CuSn10 |

CuSn6Zn6Pb3 |

- |

100Cr6 |

|

|

HBsC4 |

BC6 |

AIBC3 |

BC3 |

BC6 |

FC250 |

SUJ2 |

|

|

C86300 |

C83600 |

C95500 |

C90800 |

C83600 |

Class40 |

52100 |

|

|

HTB2 |

LG2 |

AB1 |

PB4 |

LG2 |

- |

- |

|

chemical element |

JDB-1 |

JDB-2 |

JDB-3 |

JDB-4 |

JDB-5 |

||

|---|---|---|---|---|---|---|---|

|

Cu ( % ) |

Rest |

Rest |

Rest |

- |

- |

||

|

Sn ( % ) |

- |

6 |

- |

10 |

6 |

- |

- |

|

Zn ( % ) |

25 |

6 |

- |

- |

6 |

- |

- |

|

Ni ( % ) |

- |

- |

- |

- |

- |

- |

- |

|

AI ( % ) |

6 |

- |

10 |

- |

- |

- |

- |

|

Fe ( % ) |

3 |

- |

3 |

- |

- |

Rest |

Rest |

|

Mn ( % ) |

3 |

- |

- |

- |

- |

0.905 - 1.3 |

0.20 - 0.40 |

|

Cr ( % ) |

- |

- |

- |

- |

- |

- |

1.30 - 1.65 |

|

C ( % ) |

- |

- |

- |

- |

- |

2.5 - 4 |

0.95 - 1.05 |

|

Si ( % ) |

- |

- |

- |

- |

- |

1.0 - 1.3 |

0.15 -0.35 |

|

Pb ( % ) |

- |

3 |

- |

- |

3 |

- |

- |

|

performance |

JDB-1 |

JDB-2 |

JDB-3 |

JDB-4 |

JDB-5 |

|---|---|---|---|---|---|

|

P ( N/mm2 ) |

100 |

60 |

70 |

60 |

250 |

|

MAX V ( m/s ) |

Dry0.4 oil5 |

2 |

2 |

0.5 |

0.1 |

|

MAX PV( N/mm2·m/s ) |

3.8 |

0.5 |

0.6 |

0.8 |

2.5 |

|

ρ( g/cm3 ) |

8.0 |

8.0 |

7.6 |

7.3 |

7.8 |

|

( N/mm2 ) |

> 600 |

> 250 |

> 500 |

> 250 |

> 1500 |

|

( % ) |

> 10 |

> 4 |

> 10 |

- |

- |

|

( HB ) |

> 210 |

> 80 |

> 80 |

> 160 |

HRC> 55 |

|

( ℃ ) |

300 |

350 |

300 |

400 |

350 |

|

( μ ) |

OIL: 0.03 |

DRY: 0.16 |

|||