| Brand Name: | CHINA wrapped bushing, Bronze CuSn8P, DIN 1494 / ISO 3547, Low-maintenance |

| Model Number: | Bronze Bearings and Bronze Sleeve Bushings made of CuSn8 |

| MOQ: | phosphor bronze bush,tin bronze bearings,brass bushes |

| Price: | Precision Tolerance, Factory Price |

| Payment Terms: | TT IN ADVANCE |

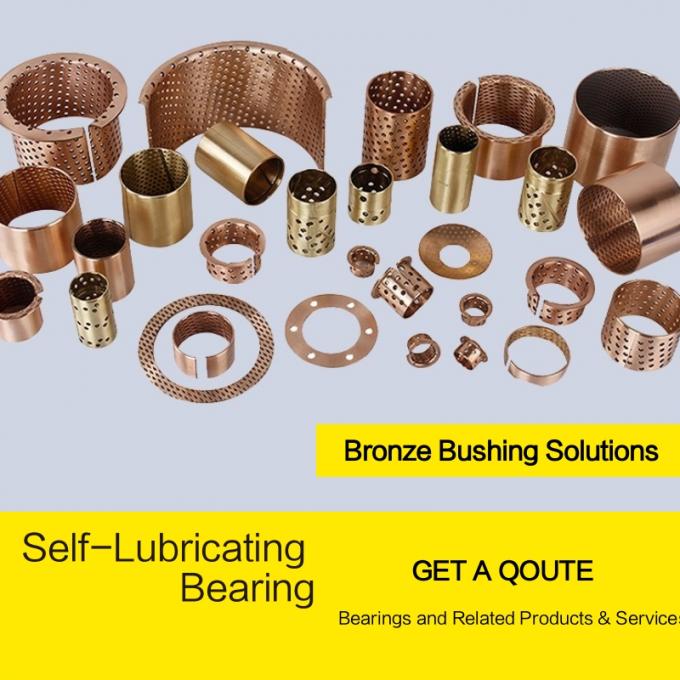

| Supply Ability: | Perforated Bronze Bearing,Plain Bronze Wrapped Bearings |

CuSn8 Bronze Bearings – Flanged, Metric, and Built for Industrial Excellence

Meta Title: CuSn8 Bronze Bearings | VIIPLUS – Flanged, Self-Lubricating Solutions for Heavy-Duty Machinery

Meta Description: Discover VIIPLUS’s CuSn8 Lubrication Bundbuchse Bronze Bearings – DIN 17662 compliant, flanged design, and metric precision. Ideal for construction, agriculture, and automotive industries. Request a quote today!

VIIPLUS sets the standard for industrial reliability with CuSn8 Lubrication Bundbuchse Bronze Bearings, engineered to deliver unmatched durability and performance. Crafted from CW453K bronze alloy (CuSn8) and compliant with DIN 17662 standards, these flanged, metric bearings combine self-lubricating technology, corrosion resistance, and heavy-load capacity. Whether for construction machinery, agricultural equipment, or automotive systems, VIIPLUS bearings ensure smooth operation in the harshest environments.

| Parameter | Details |

|---|---|

| Material | CuSn8 (CW453K) |

| Tensile Strength | ≥290 MPa |

| Elongation | ≥40% |

| Hardness | 90–120 HB |

| Temperature Range | -50°C to +200°C |

| Load Capacity | Static: 120 N/mm² |

| Tolerances | Housing H7 |

VIIPLUS CuSn8 Bronze Bearings redefine industrial durability, offering precision, self-lubrication, and heavy-load performance for the most demanding applications. From construction sites to agricultural fields, these bearings deliver reduced downtime, lower costs, and long-term efficiency.

Request Your Custom Solution Today!

[Contact VIIPLUS] for pricing, CAD models, or tailored designs. Explore our catalog of 2,000+ bronze bearings and optimize your machinery’s performance.

Keywords: CuSn8 bronze bearings, flanged wrapped bearings, metric bronze bushings, DIN 17662 compliant, VIIPLUS industrial solutions

VIIPLUS made-to-order from china bronze Cusn8 bronze sleeve bearing material is known by various names such as MBZ, B09 or MBZ B09. Buying a bronze sleeve bearing from chinese or its authorized distributors guarantees that you do not receive a counterfeit product.CuSn80.3 tin bronze is a bronze with tin as the main alloy element.Tin content is generally 3 ~ 14%, mainly used for making elastic bronze sleeve bushing and flanged bearings components and wear-resistant parts.CuSn8P0.3 CW453K US standard C52100 C5210 wear resistant tin bronze sleeve bushing and bearing.The Cusn8 or Cusn6.5 092 bronze sliding bearings are equivalent to the FB092 bearings, but with evenly distributed lubrication holes. The lubricant is dispensed into the holes during assembly. The sleeve bronze bushing sliding bearings are characterised by their good lubricant capacity and simple assembly.

With bronze sleeve products to choose from, the VIIPLUS INTERNATIONAL Series bushings are further sub-categorized by the following:Straight Bushings & Flanged Bushings.Click here BRONZE WRAPPED BUSHING WITH OIL HOLES.pdfto go to our online sliding bearings catalog and bronze bushings product specifier 090 Series Bushings including Assembly /shaft – Bearing play downloads.

This type of sliding bearing is used with medium-sized loads and low speeds, such as in transport rollers, winding equipment, anchor winches and aligning machinery.

|

BASE MATERIAL |

HARDNESS |

TEMPERATURE RANGE |

RESILIENCE |

SLIDING SPEED |

||

|---|---|---|---|---|---|---|

|

CuSn8P0.3 / CuSn6.5P0.1 |

HB90 |

HB120 |

-100°C |

+200°C |

60 N/mm2 × m/s |

2.5 m/s |

Chemical composition

Chemical composition

Sn: 7.0 to 9.0

P: 0.03 to 0.35

Zinc: 0.20 or less

Ni: 0.20 or less

Fe: 0.01 or less

Pb: 0.05 or less

Cu: allowance

Mechanical properties:

Sigma b (MPa) : ≥350

Elongation 10 (%) : ≥55

CuSn6.5P0.1 is phosphor bronze with high strength, elasticity, abrasion resistance and diamagnetization, good pressure workability in hot and cold state, high flame resistance to electric spark, weldability and fiber welding, good workability, corrosion resistance in atmosphere and fresh water.

Except for bearing, copper sleeve bushing and wear-resisting parts, it is mainly used for making wear-resisting copper mesh in papermaking industry and working parts with unit load <981Mpa and circumferential speed <3m/s.

| BASE MATERIAL | HARDNESS | TEMPERATURE RANGE | RESILIENCE | SLIDING SPEED LIMIT |

||

|---|---|---|---|---|---|---|

| CuSn8P0.3 / CuSn6.5P0.1 | HB90 | HB120 | -80°C | +200°C | 75 N/mm2 × m/s | 2.5 m/s |

| Wrapped bushing, Bronze CuSn8P, DIN 1494 / ISO 3547, Low-maintenance | |||

| TECHNICAL DETAILS | |||

| Specific load capacity static | ≤ 120 [N/mm2] | Temperature strain | - 40 [°C] to + 250 [°C] |

| Specific load capacity dynamic | ≤ 40 [N/mm2] | ||

| Sliding speed | ≤ 2.5 [m/s] depending on lubrication | Max. PV-value | 2.8 [N/mm² x m/s] |

| Friction value | 0.05 [µ] to 0.12 [µ] | ||

| MATERIALS | |||

| Support material | CuSn8P (DIN 17662) | alternative CuSn6P available | |

| TOLERANCE DETAILS | |||

| Housing Ø | H7 | Shaft tolerance | f7 to h8 |

| Bushing inner-Ø after mounting | H9 | ||

| SHAFT MATERIAL | |||

| Steel, hardened or untempered | |||

| Surface roughness ≤ Ra 0.8 | |||

| PROPERTIES | |||

| Economic solution for bronze bearing application due to a thin wall thickness. High load capability and good stability with low abrasion. Suitable for rough working conditions, good corrosion resistance. Lubrication holes for maximum grease storage and the lowest maintenance intervals. | |||

| RANGE OF APPLICATION | |||

| Agriculture machinery, truck cranes & construction machinery, suitable for impact loads | |||

| MAINTENANCE | |||

| It is a low maintenance bushing material. An initial greasing during installation is necessary, after that periodic greasing with oil or grease is mandatory. The lubrication holes are an excellent lubrication depot and keeping maintenance to a minimum. | |||

| MOUNTING ADVISE | |||

| Housing | Chamfer min. 1.5 mm x 15-45°, for easy bushing alignment | ||

| Shaft | Chamfer 5 mm x 15°, for easy insertion of the shaft | ||

| We advises to use a force fitting mandrel for the installation of the bushing. It might be necessary to apply some grease on the outer surface of the bushing when press fitting it into the housing. | |||

Bicycles, motorcycles, tools, steam Yarn Machine, reciprocating saw, Gerong machine, textile machine, knitting machine, button machine, packaging system, nailing machinery equipment, glass manufacturing equipment.