|

|

| Brand Name: | bimetal SAE-797 SAE 48 SAE-799 bushings |

| Model Number: | JF800 JF720 JF700 Bimetal Lead-Free Plain Bearings |

| MOQ: | 800 Piece/Pieces (Min. Order) |

| Price: | $0.20 - $2.00 / Pieces ,Negotiable |

| Payment Terms: | TT IN ADVANCE Western Union |

| Supply Ability: | casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing |

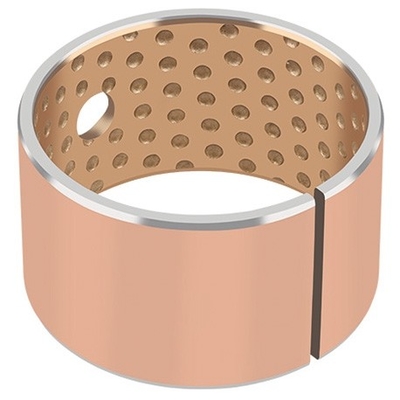

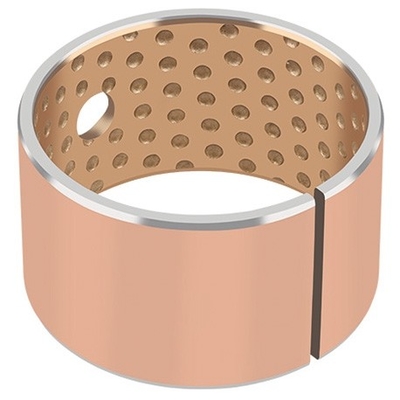

The hydraulic cargo forklift arm shaft bush and the bimetal bearing wheel groove are critical components in the operation of forklift trucks. The arm shaft bush is responsible for guiding and supporting the movement of the forklift's lifting arms, while the bimetal bearing wheel groove provides a smooth and durable surface for the wheels to rotate on.

The arm shaft bush is typically made of a wear-resistant material that can withstand the constant friction and impact caused by the lifting and lowering of heavy loads. It is designed to fit precisely into the shaft of the forklift arm, ensuring smooth and reliable movement.

The bimetal bearing wheel groove, on the other hand, is composed of two layers of metal. The outer layer is made of a harder, more wear-resistant material, while the inner layer is softer and provides a cushioning effect. This combination of materials allows the wheel groove to withstand the high loads and frequent movement of the forklift wheels while also minimizing wear and tear.

Both the arm shaft bush and the bimetal bearing wheel groove are essential for the safe and efficient operation of forklift trucks. Regular inspection and maintenance of these components are crucial to ensure their continued performance and reliability.

This type sliding bearing including engine bearing, con rod bushing truck roller bearing and other type oilless bearing.We are leading Manufacturers of Bimetal Bearing, Bronze Bearing, Sliding Bearing,Sleeve Bush Bearing, Linear Bearing. Our Manufacturing Unit is located in China.

| Bronze alloy | CuSn6.5P0.1 | Temperature Max | 200℃ |

| Load capacity | 65N/mm² | Harderness alloy | HB70~100 |

If you need help in selecting the best bimetal bearing and bushing for your particular application, Such as Material,Tolerances and Precision,Internal Clearance,Lubrication,Fitting and Mounting,Load and Life Calculation Information Shaft Dia.Shaft Size,Housing Bore Dia. Bearing Outside Diameter,Bearing Bore after Mounting Clearance,Wall Thickness ,Bearing Length Tolerance.please remember that design engineering and application assistance are available from VIIPLUS CHINA as part of our value-added services designed to make your job easier.

Sinter bronze powder: good wear resistance and excellent load carrying capacity.

Steel backing: gives exceptionally high load carrying capacity, excellent heat dissipation.

Copper plating 0.002mm, good corrosion resistance.

This bimetal bearing must be lubricated in the application.

Please review the technical information on the requirements for the mating shaft.

The Bimetal Series Bushings feature steel backed lead bronze lined material specially developed for lubricated applications, high load capacity, excellent heat dissipation, and good fatigue properties. They have been widely used in automotive industry, and general industrial applications including steering gears, power steering, pedal bushes, king-pin bushes, tailgate pivots, mechanical handling, lifting equipment, hydraulic motors, agricultural machines etc.

Bimetal bushing for trunion shaft,king pin,poston pin,connecting rod,rocker arm,leaf spring,cam shaft,crank shaft,track roller,carrier roller,idler etc.

Metal and Bimetal Bearings to standard SAE 792 & SAE 794

Hydraulic cargo lift Bushings & Sliding Bearings is safe and has a large load capacity, and convenient repair, making this special industry some faster development.Hydraulic elevator freight elevator installation of oil-free wear-resistant bearings benefits of hydraulic elevator is divided into movable and fixed type, in the shear fork type hydraulic elevator freight elevator bracket connection hole in the installation of oil-free wear-resistant bearings, this is our company's products have been used in a kind of accessories, what is the benefit of the installation? Let me just say a few words about that.

VIIPLUS offers a broad range of sizes, forms and materials in monometallic and bimetallic bearings.

|

Material

|

Steel + CuPb10Sn10

|

|

Typical Application

|

con-rod of automobile engines, engineering and agriculture machinery, heavy duty construction machinery, etc.

|

|

Max Dynamic Load

|

140N/mm²

|

|

Max Line Speed (Grease)

|

2.5m/s

|

|

Max PV Value Limit (Grease)

|

2.8N/mm².m/s

|

|

Friction Coefficient (Grease)

|

0.05~0.15

|

|

Max Line Speed (Oil)

|

5m/s

|

|

Max PV Value (Oil)

|

10N/mm².m/s

|

|

Friction Coefficient (Oil)

|

0.04~0.12

|

|

Max Working Temperature

|

Grease 150ºC, Oil 250ºC

|

|

Mating Axis

|

Hardness ≥53HB, Roughness Ra=0.32~0.63

|

|

Alloy Layer Hardness

|

60-90HB

|

|

Thermal Conductivity

|

47W/mk

|

|

Coefficient Of Linear Expansion

|

18×10-6/K

|

|

We can also develop according to customers special request while out of this table

|

|

Bimetal bearings are able to handle heavy loads and shock loading conditions. Our bimetal bearings have anti-corrosion capabilities and are easy to install, making them ideal for emergency replacements. VSB-80 Series bearing is available with stainless steel, carbon steel or bronze backing.Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments. VIIPLUS bearings can be made in many sizes and forms, including thin-walled, thick-walled, flanged, cylindrical, sintered and oil-impregnated, and more.

Cargo transportation is usually the use of automatic hydraulic lifting platform, automatic Huoti and forklifts, are widely used in various fields.

Shear fork type hydraulic elevator is the ideal equipment for vertical transport of goods, but must be properly used in order to ensure safety.

1. after the delivery of butter, there is no need to add butter in the use process, which saves your time and avoids damage to the equipment caused by forgetting maintenance.

2. the installation of oil-free wear-resisting bearing can reduce the gap of bracket connection and avoid the phenomenon of side deviation on the platform with large clearance after multiple uses.

3. increase the service life of the connecting bearings and avoid the phenomenon of fracture or propping of the connecting shaft after too many times of use.

4. enhanced the stability of the lifting and lifting of the equipment to avoid left and right sway after increasing the gap.This also shows that the installation of oil-free wear-resistant bearings to the benefits of our company equipment are installed oil-free wear-resistant bearings, so that you use more assured.

![]()

Construction site, high-rise buildings and other manned or lift mechanical equipment. the utility model is composed of a power machine and a box device, a skip car or a platform suspended by a steel wire rope. Some are also called elevators lifting operation platform is a kind of multi-functional lifting equipment, which can be divided into fixed and mobile type, guide rail type, curved arm type, shear fork type, chain type, loading and unloading platform.

Bimetal bushing & sliding bearings for aerial work platform (e.g. cherry picker or scissor lift); lift; elevator

This bearing is the kind of Flange bush with the steel backing sintered with bronze powder through the friction welding. The surface may be incorporated with various kinds of oil grooves, pockets to meet different necessities of various lubricating

conditions.

Bimetal composite bearings with high quality low carbon steel as substrate, the surface of the sinter with low friction properties of copper alloy (CuPb10Sn10 CuPb6Sn6Zn3 CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as wear-resisting layer of bearing, can need according to the operating conditions of copper alloy surface processing of various types of oil tank, oil hole, hole, etc., in order to suit to cannot continue to go hard or go occasion.Good joint strength and optimum bearing capacity can be obtained by the secondary sintering and extrusion.

VIIPLUS is mainly produce bimetallic bearing material strips and bimetal bushings technology.

![]()

This product is widely applied in various automobile engines, Aerial liftvehicle, motorcycle clutches, rubbing plate of gear pumps and other hoist machines.

Construction machinery: chassis travelling mechanism supporting wheel shaft sleeve, towing wheel shaft sleeve, tensioning wheel shaft sleeve;

Automobile industry: balance shaft bushing, steel plate pin bushing, steering knuckle main shaw shaft sleeve, connecting rod shaft sleeve, valve rocker shaft sleeve, camshaft shaft sleeve, differential shaft sleeve, transmission shaft sleeve, internal combustion engine spindle bush, thrust washer;And piston pump side piece, gear pump side piece and so on.

In practice, different grades of alloy can be sintered on the surface according to different working conditions.

| Dynamic load limit | 60N/mm² |

| Static Load | 120N/mm² |

| frictional coefficient | 0.08~0.2 |

| PV limit | 2.8N/mm²*m/s |

| Max Speed | >2m/s |

| Temp.limit |

-40°C~+250°C |

Wrapped composite sliding bearing

Copper-plated or tin-plated steel / bronze

Low-maintenance

With lubrication pockets

For high load capacity and oscillating movement, as well as for rough operation and temperature load. Long-run lubrication because of lubricant storage.

Support materialSteel copper-plated / tin-plated

Sliding layerCuPb10Sn10

Housing ØH7

Bushing inner-Ø after mountingH9

Shaft tolerancef7 to h8

is a low-maintenance composite sliding bearing, but primary lubrication is necessary. Oil or grease lubrication is possible. Due to solid lubricant storages, lubrication clearances are reduced to a minimum!

Special dimensions are available on request

You can use our “Enquiry Form” to get in touch with us. One of our sales team will contact you immediately.

FOLLOW US ON

![]()

http://www.bronzegleitlager.com