|

|

| Brand Name: | CHINA CUSTOM THERMOPLASTIC BUSHING SELF-LUBRICATING BEARINGS |

| Model Number: | CUSTOM THERMOPLASTIC AND TEX FABRIC WEAVE / GLASS FIBERS STAINLESS-STEEL 316 BEARINGS |

| MOQ: | >=500 Pieces |

| Price: | negotiate |

| Payment Terms: | TT IN ADVANCE |

| Supply Ability: | Stainless Steel Bushing Manufacturers Self Lubricating Plain Bearings Suppliers |

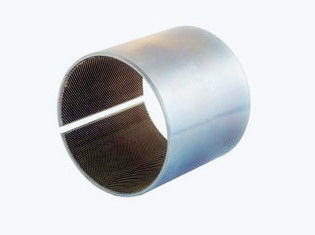

Stainless steel /Woven Fabric lined split 316 composite bearings with flanged bushes are high-performance mechanical components designed for applications requiring exceptional wear resistance, corrosion resistance, and dimensional stability. These bearings incorporate a unique combination of materials to achieve optimal performance in a wide range of industrial and commercial applications.

The stainless steel outer shell of these bearings provides excellent corrosion resistance and durability, ensuring long-lasting performance in harsh environments. The /Woven Fabric lining offers superior wear resistance and low friction properties, reducing friction and wear between moving parts. The Woven Fabric reinforcement further enhances the lining's strength and durability, making it ideal for high-load and high-speed applications.

The split design of these bearings allows for easy installation and removal, reducing downtime and maintenance costs. The 316 composite material, which is composed of stainless steel and other alloys, provides additional strength and corrosion resistance. The flanged bushes are specifically designed to fit securely within the bearing housing, preventing any unwanted movement or leakage.

Applications for stainless steel /Woven Fabric lined split 316 composite bearings with flanged bushes include industrial machinery, pumps, motors, compressors, and other rotating equipment. These bearings are ideal for applications where high temperatures, chemicals, or other corrosive environments are present. The combination of stainless steel, /Woven Fabric lining, and 316 composite material ensures that these bearings can withstand extreme conditions while maintaining superior performance.

Overall, stainless steel /Woven Fabric lined split 316 composite bearings with flanged bushes offer a reliable and durable solution for applications requiring high-performance bearings. The unique combination of materials and design ensures optimal performance in a wide range of industrial and commercial applications.

| Part Size | Part Description |

| 12-14-20 | SS Backed 316 BACKED PTFE Type Bush |

| 16-18-20 | SS Backed 316 BACKED PTFE Type Bush |

| 20-23-25 | SS Backed 316 BACKED PTFE Type Bush |

| 30-34-40 | SS Backed 316 BACKED PTFE Type Bush |

| 40-44-50 | SS Backed 316 BACKED PTFE Type Bush |

| 50-55-60 | SS Backed 316 BACKED PTFE Type Bush |

| 60-65-70 | SS Backed 316 BACKED PTFE Type Bush |

| 60-65-30 | SS Backed 316 BACKED PTFE Type Bush |

| 80-85-80 | SS Backed 316 BACKED PTFE Type Bush |

| 90-95-60 | SS Backed 316 BACKED PTFE Type Bush |

| 10-12-20 | SS Backed 316 BACKED PTFE Type Bush |

| 70-75-50 | SS Backed 316 BACKED PTFE Type Bush |

| 25-28-30 | SS Backed 316 BACKED PTFE Type Bush |

| 35-39-40 | SS Backed 316 BACKED PTFE Type Bush |

| 80-85-60 | SS Backed 316 BACKED PTFE Type Bush |

| 90-95-50 | SS Backed 316 BACKED PTFE Type Bush |

| 100-105-70 | SS Backed 316 BACKED PTFE Type Bush |

| 22-25-25 | SS Backed 316 BACKED PTFE Type Bush |

| 40-44-25 | SS Backed 316 BACKED PTFE Type Bush |

| 100-105-50 | SS Backed 316 BACKED PTFE Type Bush |

| 130-135-100 | SS Backed 316 BACKED PTFE Type Bush |

| 140-145-100 | SS Backed 316 BACKED PTFE Type Bush |

| 165-170-100 | SS Backed 316 BACKED PTFE Type Bush |

| 30-34-30 | SS Backed 316 BACKED PTFE Type Bush |

| 14-16-20 | SS Backed 316 BACKED PTFE Type Bush |

| 50-55-30 | SS Backed 316 BACKED PTFE Type Bush |

| 16-18-15 | SS Backed 316 BACKED PTFE Type Bush |

| 25-28-20 | SS Backed 316 BACKED PTFE Type Bush |

| 30-34-20 | SS Backed 316 BACKED PTFE Type Bush |

| 35-39-25 | SS Backed 316 BACKED PTFE Type Bush |

| 45-50-50 | SS Backed 316 BACKED PTFE Type Bush |

| 45-50-30 | SS Backed 316 BACKED PTFE Type Bush |

| 65-70-70 | SS Backed 316 BACKED PTFE Type Bush |

| 20-23-30 | SS Backed 316 BACKED PTFE Type Bush |

| 115-120-100 | SS Backed 316 BACKED PTFE Type Bush |

| 115-120-70 | SS Backed 316 BACKED PTFE Type Bush |

| 90-95-100 | SS Backed 316 BACKED PTFE Type Bush |

| 100-105-100 | SS Backed 316 BACKED PTFE Type Bush |

| 95-100-100 | SS Backed 316 BACKED PTFE Type Bush |

| 95-100-50 | SS Backed 316 BACKED PTFE Type Bush |

| 14-16-25 | SS Backed 316 BACKED PTFE Type Bush |

| 16-18-25 | SS Backed 316 BACKED PTFE Type Bush |

| 110-115-100 | SS Backed 316 BACKED PTFE Type Bush |

| 180-185-100 | SS Backed 316 BACKED PTFE Type Bush |

| 80-85-100 | SS Backed 316 BACKED PTFE Type Bush |

| 95-100-60 | SS Backed 316 BACKED PTFE Type Bush |

| 105-110-60 | SS Backed 316 BACKED PTFE Type Bush |

| 105-110-100 | SS Backed 316 BACKED PTFE Type Bush |

| 105-110-115 | SS Backed 316 BACKED PTFE Type Bush |

| 130-135-60 | SS Backed 316 BACKED PTFE Type Bush |

| 150-155-60 | SS Backed 316 BACKED PTFE Type Bush |

| 60-65-60 | SS Backed 316 BACKED PTFE Type Bush |

| 60-65-50 | SS Backed 316 BACKED PTFE Type Bush |

| 115-120-80 | SS Backed 316 BACKED PTFE Type Bush |

| 210-215-180 | SS Backed 316 BACKED PTFE Type Bush |

| 210-215-100 | SS Backed 316 BACKED PTFE Type Bush |

| 255-260-100 | SS Backed 316 BACKED PTFE Type Bush |

| 255-260-160 | SS Backed 316 BACKED PTFE Type Bush |

| 255-260-200 | SS Backed 316 BACKED PTFE Type Bush |

| 105-110-50 | SS Backed 316 BACKED PTFE Type Bush |

| 200-205-150 | SS Backed 316 BACKED PTFE Type Bush |

| 200-205-80 | SS Backed 316 BACKED PTFE Type Bush |

| 240-245-100 | SS Backed 316 BACKED PTFE Type Bush |

| 240-245-180 | SS Backed 316 BACKED PTFE Type Bush |

| 240-245-200 | SS Backed 316 BACKED PTFE Type Bush |

| 95-100-80 | SS Backed 316 BACKED PTFE Type Bush |

| 35-39-50 | SS Backed 316 BACKED PTFE Type Bush |

| 35-39-30 | SS Backed 316 BACKED PTFE Type Bush |

| New -coated lubricating bearings |

| and other new sleeve bushing products |

Glycodur Bushings Replacement

Self Lubricating Flange Bearing With / Woven Fabric sliding Layer, What We Do Manufacturing in China Plant Certifications Design Challenge Industry Solutions.

Oilless bearing is a new type of bearing with the characteristics of metal bearing and oil - free bearing. As a supplier of plain bearings, the oil-free bearings also become the industry benchmark.

The high-performance dry friction bearing in China can run without oil or less oil through the low friction packing in the sliding layer. Lubrication has always been a headache for industrial designers. It is expensive and brings a lot of pollution, which is very unfriendly to the environment. This article will introduce the knowledge of lubrication and the specific application of VIIPLUS oil-free bearing.

You have access to the latest downloads here. Click on the Wrapped Composite Sliding Bearing.pdf catalog symbol to display the file, and download the self-lubricating bushing bearings catalog file.

1:increase the cost; Processing oil lines or oil lines in the shaft or housing, purchasing lubricating oil, reducing operating efficiency during maintenance due to machine downtime, additional sealing to maintain lubricant, recycling of machines, and so on all cost you a lot.

2.: reduce the oil seal and shaft between the contact energy efficiency.

3: add lubrication and use in the process of environmental pollution risk.

Self-lubricating Bushing & Bearing Tin Plating and Copper Plating, If you have an application that calls for your part to be altered, we can meet your needs. From Composite Bearings Material, boring the I.D., turning the O.D., self-lubricating bearings holes, or flange, chamfering, thrust washer, or any other drawings custom bushing work… we have the technology to do it all.We are able to offer lined wrapped bearings in metric plain, imperial plain, metric flanged, metric washers, imperial washers, metric strip, and imperial strip. Special sizes can be produced to customer requirements.

VIIPLUS offers a broad range of sizes, forms, and materials in Stainless Steel Composite Bearings and Bushings offer corrosion resistance excellent corrosion resistance in industrial outdoor applications and in water, marine and offshore environments.

Bushes are suitable for Chemical valve, chemical pump, flow meter, food industry, medicine industry in the corrosion environment.transmission, rotational and oscillating movements. Rod guide for pneumatic and hydraulic cylinders.Attachment lugs of pneumatic and hydraulic cylinders.Conveyor-belt systems, textile machinery, automobiles.

Low friction and high wear resistance with no lubrication.

Stainless steel bearing uses the or fibers fabric and aramid fiber overlay on metal backings, the fabric has very high load capacity and high accuracy good run with low speed and heavy friction superior performance, widely used in heavy equipment like construction machinery, agriculture machinery.

Note: the products in the figure can also choose different matrix materials according to different working conditions, such as a bronze substrate (VSB-1b), stainless steel substrate (VSB-1s), and lead-free (VSB-1w) formula products

| Performance indicators | Date | |

| Maximum load P | Static load | 250N/mm² |

| Dynamic load | 140N/mm² | |

| Maximum linear velocity V | Dry friction | 2.5m/s |

| Oil lubrication | 5.0m/s | |

| High PV value | Dry friction | 3.8N/mm²・m/s |

| Oil lubrication | 50N/mm²・m/s | |

| Coefficient of frictionμ | 0.04~0.20 | |

| The use of temperature | -195℃~+280℃ |

|

| Coefficient of thermal conductivity | 50W/m・K |

|

Wrapped composite sliding bearing Stainless steel 316 / fibers fabric

Stainless Steel 316 Bearings + Fabric stainless steel-based non-oil lubricated

Viiplus Is A Professional Production Of Stainless Steel Bushing Manufacturers. Bearings and shafts made of stainless steel and are maintenance-free.

Stainless Steel Bushings That Can Withstand Moisture And A Number Of Corrosion Caused By Other Media. We produce bearing made of stainless steel 304&316. Characteristics of high strength, wear resistance, corrosion resistance, and corrosion resistance, etc. Stainless steel backing sintered with bronze powder overlaid with fibers fabric Suitable for dry running, low coefficient of friction, lower wear.

Industrial Steel Bushes 304 Vs 316 Stainless Steel Bushings

304 and 316 stainless steel bearing material is different: corrosion resistance: 316 stainless steel bearing Mo, then 304 stainless steel bearing in the high-temperature environment corrosion resistance is better, so in the high-temperature environment, engineers will generally choose 316 material parts.316 mainly reduced Cr content, increased Ni content, and increased Mo2%~3%. Therefore, its corrosion resistance is stronger than 304, suitable for use in the chemical industry, seawater, and other environments

This material meets the demanding criteria for long life and trouble-free performance with or without lubrication.

Composite dry sliding bearings are primarily used for bearing arrangements where heavy loads have to be supported and where rotational or oscillating movements are relatively slow.

Because of their good sliding properties and compact design, these plain bearings are particularly suitable for bearing arrangements where:

Maintenance-free operation is a prerequisite

There is a risk of lubricant starvation Lubricants cannot be used or are forbidden Space is limited.

Maintenance-free operation

No lubrication required ( composite)

Initial lubrication required (POM composite)

Minimum wall thickness, minimum space requirements

Accommodation of heavy loads

Wide range of temperatures

Good sliding properties

Virtually no stick-slip

High wear resistance

Less sensitive to edge loading (POM composite)

No machining required.

The standard range of composite plain bearings is very comprehensive and covers almost every standard size. This range comprises straight and flanged bushings, thrust washers, and strips.

I.D. = inner diameter O.D. = Outer diameter

| Model No. | Min. I.D. | Min.O.D. | Max.I.D. | Max.O.D. | Max. Length |

| VSB-10,DU,SF-1 | 6mm | 8mm | 300mm | 305mm | 100mm |

| VSB-20,DX,SF-2 | 10mm | 12mm | 300mm | 305mm | 100mm |

| VSB-80,JF800 | 10mm | 12mm | 173mm | 180mm | 100mm |

| VSB-22,FB090 | 10mm | 12mm | 300mm | 305mm | 100mm |

| VSB-22,FB092 | 10mm | 12mm | 300mm | 305mm | 100mm |

| VSB-50,JDB | 8mm | 12mm | 160mm | 180mm |

150mm |

VIIPLUS Sliding bearing solutions for your applications

Wrapped composite sliding bearing

Carbon-steel / fibres fabric

Maintentance-free

Available on request

Excellent sliding and wear behavior, especially in case of rotating and oscillating movement, good shock absorption, very high load capacity, no water absorption

Support material carbon steel bushings

Sliding layer fibers fabric bushing

Support material: Stainless steel and bronze on request

Specific load capacity static≤ 350 [N/mm2]

Specific load capacity dynamic≤ 180 [N/mm2]

Sliding speed< 0.5 [m/s] 1 [m/s] lubricated

Friction value ***0.03 [µ] to 0.20 [µ]

Temperature strain– 50 [°C] to + 250 [°C]

Max. PV-value1.8 [N/mm² x m/s]

The application of an adequate force-fitting mandrel is advisable

Housing ØH7

Bushing inner-Ø after mountingH9

Shaft tolerancef7 to h8

|

Tech.Data |

|||||

|

Max.Load |

Static |

350N/mm2 |

|

Temp. |

-50°C~+250°C |

|

Dynamic |

180N/mm2 |

||||

|

Friction coefficient |

0.03~0.20 |

||||

|

Max.speed |

Dry |

0.5m/s |

|||

|

Thermal conductivity |

42W(m x K) 1 |

||||

|

Grease |

1m/s~3m/s |

||||

|

Max.PV(Dry) |

Short-term |

3.6N/mm2 m/s |

Coefficient of thermal |

11 x 10- 6 x K-1 |

|

|

Continuous |

1.8N/mm2 m/s

|

||||

is a dry sliding bearing with glued fibers fabric overlay? Lubrication is therefore not necessary and not allowed.

Machine and crane construction, apparatus engineering, agricultural machines, fittings, water pumps, chemical industry

This sliding bearing type and special dimensions are only available on request

Get in touch ...Send us an online enquiry.You can use our “Enquiry Form” to get in touch with us. One of our sales team will contact you immediately. pragmatic solutions – high-quality products – premium service – fair prices

steel bearing USA, stainless steel broccoli

![]()

FOLLOW US ON

![]()