|

|

| Brand Name: | VIIPLUS |

| Model Number: | Polymer Plain Bearings Types |

| MOQ: | negotiable |

| Price: | Competitively Priced vs , Provides Lubricating Bush |

| Payment Terms: | T/T |

| Supply Ability: | Flanged Bronze Bushings, Bronze Thrust Washers, Self Lubricating Bronze Bushings |

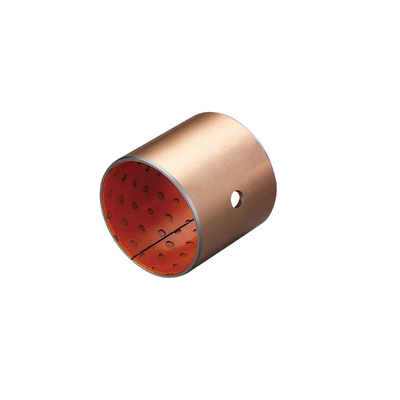

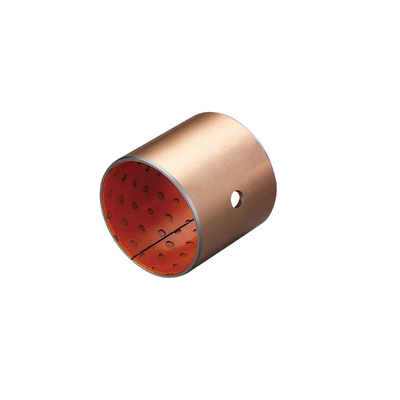

Polymer plain bearings, specifically the composite self-lubricating red bushing without Pb, are a type of bearing that utilizes the unique properties of polymers and (Polytetrafluoroethylene) to provide smooth and efficient movement while minimizing wear and friction. These bearings are designed to operate without the need for external lubricants, making them ideal for applications where lubricant contamination or leakage is unacceptable.

The red composite material used in these bushings offers excellent chemical resistance and low coefficient of friction, resulting in long-lasting and reliable performance. The absence of Pb (lead) in the material ensures compliance with environmental regulations and safety standards.

These polymer plain bearings are commonly used in a wide range of industries, including automotive, aerospace, machinery, and more. Their ability to self-lubricate and operate efficiently under various conditions makes them a valuable addition to any mechanical system requiring smooth and reliable movement.

Metal-Polymer Bearings - Plain Bearings & Self-lubricating made to order from china,Composite bearing structure: Thermoplastic bearings and bearings made of . The superior performance of polymer metal plain bearings lies in their unique composite structure: impregnated anti-friction coating enriched with and fillers or extruded thermoplastic tape; Porous sintered bronze intermediate layer for high wear resistance.

|

Size |

customizable |

|

Certification |

ISO9001 |

|

Processing methods |

Cold-extrusion |

|

Surface treatment |

Tin plating /Copper plating |

|

Operating temperature |

-200~280 |

|

Application field |

Printing machine, Textile machine, Tobacco machine, Gymnastic equipment.etc |

|

Material |

Steel base+ Bronze powder+ (RED) |

Hydraulic special bearing, is combined with the working principle of oil cylinder and shock absorber and design of a new type of material, in the condition of no oil appears to be more wear resistant, the product is especially suitable for the reciprocating frequent large trend force occasions.Suitable for automobile, motorcycle shock absorber and various hydraulic cylinder and other fields

![]()

| Performance indicators | Data | |

| Maximum load(P) | Static load | 250N/mm² |

| Dynamic load | 140N/mm² | |

| The highest line speed(V) | Dry friction | 2.5m/s |

| Oil lubrication | 5.0m/s | |

| High PV value | Dry friction | 3.8N/mm²・m/s |

| Oil lubrication | 50N/mm²・m/s | |

| The coefficient of friction(μ) | 0.04~0.20 | |

| The use of temperature | -195℃~+280℃ |

|

| Coefficient of thermal conductivity | 42W/m・K |

|

Agricultural machinery:tractors, combine harvesters, crop spray YunQi, bulldozer, grader, etc;

Auto industry: the power steering pump,steering thrust pads,brake disc,shock absorber, door hinge, wiper,chairs,illustrates,air valve and solenoid valve, etc.;

Office business machines:photocopiers, fax machines, printers,E-mail processor,etc.;

hydraulic components and valves:gear pump,ram pump,vane pump, ball valve, butterfly valve, cylinder, cylinder and other hydraulic components, etc.

Household appliances: refrigerators, air conditioners, vacuum cleaners, sewing machine,washing machine, microwave oven and fitness equipment, etc.

other logistics machinery:packaging machinery, textile machinery, port machinery, mining machinery, forest machinery and all kinds of engineering machinery and equipment.

Product advantages:

Chemical properties

polymer surface resistance to chemical corrosion, so its corrosion resistance mainly depends on the steel back of plating and appearance. The steel back of tin or copper plated surface, can effectively prevent atmospheric corrosion; If you work in the corrosive medium, the steel back can be galvanized, etc.