|

|

| Brand Name: | Straight Sleeve Bore Bushings |

| Model Number: | sleeve Bushing Applications include valves, commercial fire sprinkler systems, mixers, blenders, swivels, and extruders. |

| MOQ: | 100 Piece/Pieces (Min. Order) |

| Price: | Negotiable |

| Payment Terms: | TT IN ADVANCE |

| Supply Ability: | Valve Split Steel Bushings Shaft Bearings Suppliers |

Cylinder bronze components valve bushings are crucial elements in the hydraulic industry pumps. They serve as a vital connection point between the cylinder and the valve, ensuring smooth and efficient operation. Made from high-quality bronze, these bushings exhibit excellent wear resistance and durability, making them suitable for use in high-pressure and high-temperature environments.

The precision manufacturing process ensures that these bushings fit perfectly into the cylinder and valve, minimizing leakage and maximizing performance. Their reliability and durability contribute to the overall efficiency and longevity of the hydraulic pumps, reducing maintenance costs and downtime.

In addition, the bronze material offers excellent corrosion resistance, making these bushings suitable for use in a wide range of hydraulic applications, including water pumps, oil pumps, and other fluid handling systems.

Overall, cylinder bronze components valve bushings are an essential component of hydraulic industry pumps, providing a reliable and durable solution for efficient fluid handling.

Sleeve Bushings Manufacturer,Plain Bearings Price,made-to-order online Precision Industrial Sliding Bearings: Supply Plain Bearings and self-lubricating Bronze Bushings.

Offer self-lubricating bearings & cast bronze bushings for solutions across industries.

VIIPLUS INTERNATIONAL CHINA Committed to the production and development of hydraulic components, hydraulic systems and hydraulic machinery shaft sleeve, constantly improve the quality of sliding bearings, improve the performance of products.For metallurgical machinery, engineering machinery and coal machinery and other industries to provide hydraulic system and hydraulic components of self-lubrication bearing solutions.

Hydraulic element sliding bearing

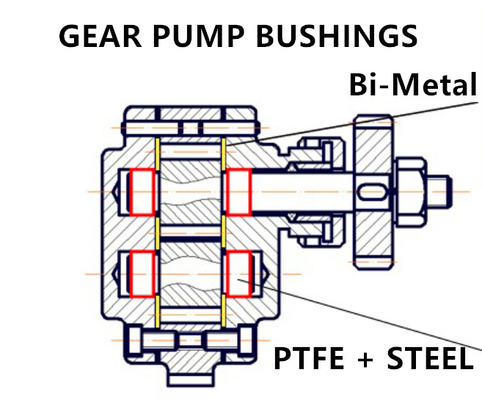

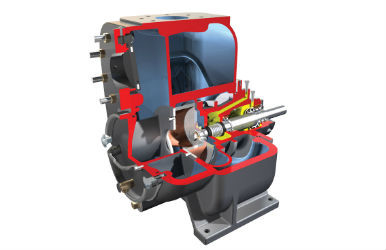

The company has developed metal and plastic self-lubricating rolling bearings suitable for high load and high speed under the condition of fluid lubrication, which are widely used in gear pump, plunger pump, vane pump, compressor, cylinder and other industries.

Bronze Sleeve Bushing Components for the Hydraulic Industry

Power and reliability, coupled with low operating costs make hydraulic cylinders plain bearings in such as metal stamping and forming and heavy mobile equipment applications.

CONSTRUCTION MACHINERY | Self-Lubricating Bearings Hydraulic plunger pump bushing | VSB-40

VIIPLUS Metal bearings are used in the engines and hydraulic systems of excavators and other construction machinery.

Auto transmission parts automobile steering system flange bushing and bearings for sale

VIIPLUS Self-Lubricating Bearings Material provides high-end casting to our valve divisions including materials like (low temperature) carbon steel/ stainless steel/ Bushing POM Bushes and high bronze alloy steels bearings.All analyses regarding the mold and pattern designs are being performed in our own premises in order to guarantee a constant casting level and quality.

VIIPLUS offers a variety of services to our global customer base that will enhance the experience of purchasing valves Bushing & Bearings from VIIPLUS and add value to your investment from pre-sales consultancy to continuous aftersales service

VSB-40 Metal-Polymer Low Friction Plain Bearings

viiplus provides a complete set of sliding bearing solutions for hydraulic system users. The supplied products include: gear pump aluminum seat assembly, axle sleeve, side plate; Blade pump and plunger pump with oil plate, return disk, axle sleeve; Cylinder liner and so on.

![]()

VSB-40 Metal-Polymer Low Friction Plain Bearings low friction bushings offer good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

· Very good performance in lubricated applications

· Good performance in greased applications

· Suitable for linear, oscillating and rotating movements

Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, the transfer film created can protect the mating metal surfaces, suitable for rotating and oscillating movement, high chemical resistance, low absorption of water and swelling. The VSV-40 improved the friction and much good wear resistance over the common CSB-10 range under lubricated operation.

| Wrapped sliding bearing, bronze/ sliding layer, DIN 1494/ISO 3547, Maintenance-free | |||

| TECHNICAL DETAILS | |||

| Specific load capacity static | ≤ 250 [N/mm2] | Temperature strain | -200 [°C] to +280 [°C] |

| Specific load capacity dynamic | ≤ 140 [N/mm2] | ||

| Sliding speed | ≤ 2.5 [m/s] | Max. PV-value | 1.8 [N/mm² x m/s] 3.6 [N/mm² x m/s] for short time |

| Friction value | 0.03 [µ] to 0.25 [µ] | ||

| MATERIALS | |||

| Support material | Bronze | Intermediate layer | Sintered bronze |

| Sliding layer | |||

| TOLERANCE DETAILS | |||

| Housing Ø | H7 | Shaft tolerance | f7 or h8 |

| Bushing inner-Ø after mounting | H9 | ||

| SHAFT MATERIAL | |||

| Steel, hardened or untempered. | |||

| Surface roughness ≤ Ra 0.8 | |||

| PROPERTIES | |||

| It is a maintenance-free material due to the sliding layer. Outstanding sliding and wear performance. High load capacity and very versatile bushing.Extended performance due to the bronze backing. | |||

| RANGE OF APPLICATION | |||

| hydraulic cylinders, cranes and construction machinery, all sorts of production machinery, pumps and medial devices | |||

| MAINTENANCE | |||

| It is maintenance-free with a sliding layer. It is not necessary to lubricate this material, but basically possible! | |||

| MOUNTING ADVISE | |||

| Housing | Chamfer min. 1.5 mm x 15-45°, for easy bushing alignment | ||

| Shaft | Chamfer 5 mm x 15°, for easy insertion of the shaft | ||

| We advises to use a force fitting mandrel for the installation of the bushing. It might be necessary to apply some grease on the outer surface of the bushing when press fitting it into the housing. | |||

| Gluing | Adhesive should not contact the sliding surface! | ||

1. /Polymer fibres mixture thickness 0.01~0.03mm. Lead-free bearing layer provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the mixture.

3. Steel backing, provides high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

5. Steel + Bronze Powder + /Fibre(Metal-Polymer Low Friction Plain Bearings)

· Metal-Polymer Composite Bushing Material

· Steel back + Porous Bronze Sinter +

· + Fillers

|

|

Sliding layer |

|

Max. load |

Static |

250N/mm2 |

Max.speed |

Dry running |

0.08~0.20 |

|

Very low speed |

140N/mm2 |

Hydrodynamicoperation |

0.02~0.08 |

||

|

Rotatingoscillating |

60N/mm2 |

Frictioncoefficient |

Dry |

2m/s |

|

|

Hydrodynamic |

>2m/s |

||||

|

Max. PVdryrunning) |

Short-termoperation |

3.6N/mm2*m/3 |

Thermal conductivity |

42W(m*K)-1 |

|

|

Continuousoperation |

1.8N/mm2*m/3 |

||||

|

PV max. hydrodynamic |

-195℃~+280℃ |

Coefficient of thermalexpansion |

11*10-6*K-1 |

||

|

OPERATING PERFORMANCE |

|

|

Dry |

Good |

|

Oil lubricated |

Very Good |

|

Grease lubricated |

Good |

|

Water lubricated |

Fair |

|

Process fluid lubricated |

Good |

* Depending on operating conditions

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

· Thrust washers

· Flanged washers

![]()

![]()

![]()

![]()

![]()

Metric bearings and imperial bushings made to order: Standard bushing forms in special sizes, half-bushings, stamped/deep drawn shapes, bearings with locating notches, lubricant holes and grooves, customized designs

FOLLOW US ON

![]()

http://www.bronzegleitlager.com