|

|

| Brand Name: | Straight Sleeve Bore Bushings |

| Model Number: | sleeve Bushing Applications include valves, commercial fire sprinkler systems, mixers, blenders, swivels, and extruders. |

| MOQ: | 100 Piece/Pieces (Min. Order) |

| Price: | Negotiable |

| Payment Terms: | TT IN ADVANCE |

| Supply Ability: | Valve Split Steel Bushings Shaft Bearings Suppliers |

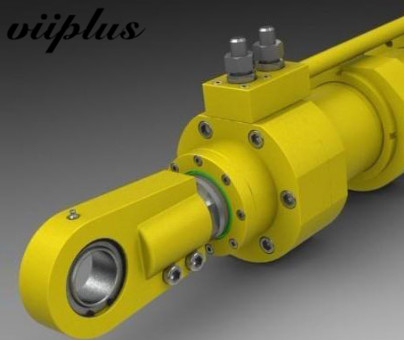

Self-lubricating bushings are a crucial element in the hydraulics industry, playing a vital role in ensuring the smooth and efficient operation of hydraulic systems. These bushings are designed to provide long-lasting lubrication, reducing friction and wear, which can lead to increased system performance and durability.

The self-lubricating feature of these bushings eliminates the need for regular lubrication, making maintenance easier and reducing operational costs. This feature is achieved through the use of special materials or coatings that naturally release lubricant as they operate.

The hydraulics industry relies heavily on precision components to handle high-pressure fluids, and self-lubricating bushings are an excellent choice for such applications. They can be found in various hydraulic systems, including pumps, valves, cylinders, and other critical components.

By focusing on hydraulics industry needs, manufacturers of self-lubricating bushings can provide customized solutions that meet specific performance requirements. This ensures that the bushings integrate seamlessly into the hydraulic system, delivering optimal performance and reliability.

In summary, self-lubricating bushings are an essential component in the hydraulics industry, enabling efficient and durable fluid handling while reducing maintenance requirements. By focusing on industry needs, manufacturers can provide tailored solutions that meet the unique challenges of hydraulic systems.

VSB-40 Metal-Polymer Low Friction Plain Bearings

· Metal-Polymer Composite Bushing Material

· Steel back + Porous Bronze Sinter +

· + Fillers

|

Sliding layer |

Tech. Data

| Max. load | Static | 250N/mm2 | Max.speed | Dry running | 0.08~0.20 |

| Very low speed | 140N/mm2 | Hydrodynamicoperation | 0.02~0.08 | ||

| Rotatingoscillating | 60N/mm2 | Frictioncoefficient | Dry | 2m/s | |

| Hydrodynamic | >2m/s | ||||

| Max. PVdryrunning) | Short-termoperation | 3.6N/mm2*m/3 | Thermal conductivity | 42W(m*K)-1 | |

| Continuousoperation | 1.8N/mm2*m/3 | ||||

| PV max. hydrodynamic | -195℃~+280℃ | Coefficient of thermalexpansion | 11*10-6*K-1 | ||

| OPERATING PERFORMANCE | |

| Dry | Good |

| Oil lubricated | Very Good |

| Grease lubricated | Good |

| Water lubricated | Fair |

| Process fluid lubricated | Good |

|

GENERAL |

|

Unit |

Value |

|---|---|---|---|

| Maximum load, p |

Static |

N/mm2 |

250 |

| Operating temperature |

Min |

°C |

- 195 |

| DRY | |||

| Maximum sliding speed, U | m/s | 2.0 | |

| Coefficient of friction | 0.03 - 0.20 * |

| OIL LUBRICATED | |||

| Maximum sliding speed, U | m/s | >2.0 | |

* Depending on operating conditions

| Max. load | Static | 250N/mm2 |

| Dynamic | 140N/mm2 | |

| Max. speed | Dry | 2m/s |

| Lubrication | >2m/s | |

| Max. PV (Dry) | Short-time | 3.6N/mm2*·m/s |

| Continuous | 1.8N/mm2*·m/s | |

| PV | Hydrodynamic | 30N/mm2*·m/s |

| Temp. | -195℃~+280℃ | |

| Friction coefficient | 0.03~0.20 | |

| Thermal conductivity | 42W (m·k)-1 | |

| Coefficient of thermal expansion | 11*10-6k-1 |

|

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

· Thrust washers

· Flanged washers

![]()

![]()

![]()

![]()

![]()

Metric bearings and imperial bushings made to order: Standard bushing forms in special sizes, half-bushings, stamped/deep drawn shapes, bearings with locating notches, lubricant holes and grooves, customized designs

VSB-40 is developed for high duty, oil lubricated, hydraulic applications...Automotivesuspensionstruts,absorbers guide bushing, hydraulic cylinders, gear pumps, motors, axial and radial piston pumps & motors.VSB-40 is designed mainly for using under lubricated conditions and it performs excellent wear resistance and low static/dynamic shockfriction coefficient.

![]()

START YOUR

PROJECTWITH AN APPLICATION ENGINEER

![]()