-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

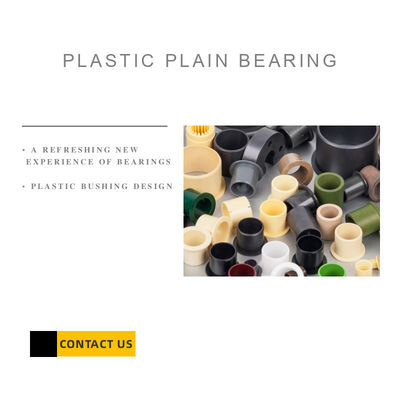

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Thermoplastic plastic sliding bearing, plastic, Maintenance-free

| Place of Origin | MADE IN CHINA |

|---|---|

| Brand Name | Thermoplastic plastic sliding bearing |

| Certification | CUSN8,CUSN6.5 Bronze |

| Model Number | Plastic Bearings |

| Minimum Order Quantity | 1000 Piece/Pieces (Min. Order) |

| Price | $0.20 - $10.00 / Pieces |

| Packaging Details | Wooden pallets for standard export packing cartons |

| Delivery Time | 10~15 work days |

| Payment Terms | T/T PREPARD, T/T, L/C, D/A, D/P |

| Supply Ability | 2000000 Piece/Pieces |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Thermoplastic Plastic | Application | Packaging Machinery |

|---|---|---|---|

| Size | Customized | Type | Plastic Plain Bearings |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | plastic flanged sleeve bearings,igus plastic bushings |

||

Maintenance-free Plastic Plain Bearings, Plastic Bushings Solution

Plastic bushings have already replaced bronze in thousands of applications from a variety of industries, including agricultural machinery, lawn mowers, medical equipment, food processing machines, fitness equipment, pumps and valves.

Learn how self-lubricating plastic bushings have been proven to deliver a longer service life than oil-impregnated sintered bronze bearings.

EP series of high performance technical plastic polymer bearings as a base material, through the modification of the technology of polymeric materials in high resistance fibers and a solid improvement of its wear resistance integrated with internal grease; high resistance to the network structure reinforced with material fibers, the special solid composite grease allows EP series plastic bearings with excellent self-lubricating properties and wear resistance. Whether it's high-end requirements in the automotive industry.

Thermoplastic plastic sliding bearing, plastic, Maintenance-free, Compound plastic produced by injection-molding.

Plastic Plain Bearings Metric Cylindrical Bushes & Flange Bearings made to order from china.

Bearings Black Lubricating Bushes h9 H7 tolerances.Such bearings are most widely applied as self-lubricating plastic bearings;

EP plastic bushing integral lubricating material has long service life

Because EP series bearing grease is contained in the whole material, no matter how long the bearing is working, the grease will constantly seep out from the friction surface for long-term lubrication, while traditional powder metallurgy oil-impregnated bearings use the micropores in the process of use. Lubricating oil has a self-lubricating effect. When the lubricating oil is exhausted or volatilized, bearing wear will increase rapidly, and the effective service life of the bearing will be announced at this time.

Plastic Bushings Characteristics

VIIPLUS bearings series material is a thermal mould character plastic processed by crystal engineering plastic as basic material with proper intensifier and lubricant. The rigidity and high temperature engineer capability is greatly improved because of the use of intensifier, at the same time, the coefficient of thermal expansion, moulding shrinking rate and wriggle capability decreases, consequently, the size stability is improved, and series material range is enlarged and keeps the intrinsic anti-wear capability and anti-drug capability.

![]()

Plastic Bushings Typical Applications

·Office Machinery

·Electronic Products

·Textile Machinery

·Fitness Machinery

·Agricultural Machinery

·Packaging Machinery

·Automotive Industry

Solid-lubricating and Maintenance-free Sliding Bearings

Plastic bearing has longe service vs Metal bearing lubricating oil is life easy to be failed

Engineers are dedicated on the performance improvement on the self- lubricating materials derives the result that EP Series Materials are with excellent self- lubricating features and wear resistance Features. High- strength fibers used in the engineering plastics fantastically improve the material load (Graphl). Special grease immersion in the plastic can decrease the friction coefficient of the material therefore to proiong the bearing sevice life. High-performance engineering plastics body material mainly service as wear- resistant vector. The reinfoced fiber improves the load and impact resistant capacity of the beaing. Special grease decreases the fiction coefficient for a better selflubricating performance.

Plastic Bushings Material property sheet

|

Common Capability |

Unit |

EPT |

EPG |

EPH |

EPX |

EPJ |

EPS |

|

Density |

g/cm³ |

1.46 |

1.46 |

1.65 |

|

1.49 |

1.24 |

|

Color |

|

Black gray |

Dark grey |

Grey |

Black |

Yellow |

Beige |

|

Max.water absorption,23℃/ 50% |

[% weight] |

0.2 |

0.7 |

0.1 |

|

0.3 |

2.02 |

|

Max.water absorption |

[% weight] |

<1.2 |

<4 |

<0.3 |

<0.5 |

<1.3 |

<0.1 |

|

Dynamic friction /steel |

μ |

0.05-0.15 |

0.08-0.18 |

0.07-0.20 |

0.09-0.27 |

0.06-0.18 |

0.05-0.15 |

|

Max.PV(dry) |

MPa•m/s |

0.4 |

0.5 |

1.37 |

1.32 |

0.34 |

0.4 |

|

Mechanical behavior |

|||||||

|

E-module |

MPa |

2,300 |

7,800 |

12,500 |

8,100 |

2,400 |

830 |

|

Tensile strength,20℃ |

MPa |

80 |

200 |

175 |

170 |

73 |

18 |

|

Compressive strength |

MPa |

65 |

80 |

90 |

150 |

35 |

10 |

|

Max.static pressure of the surface,20℃ |

MPa |

35 |

80 |

150 |

90 |

20 |

10 |

|

Shore D hardness |

|

70 |

112 |

87 |

85 |

74 |

73 |

|

Physical and thermal properties |

|||||||

|

Continuous work tempreature |

℃ |

+80 |

+130 |

+200 |

+250 |

+90 |

+260 |

|

short-time work tempreature |

℃ |

+120 |

+220 |

+240 |

+315 |

+120 |

+310 |

|

Minimum operating temperature |

℃ |

-40 |

-40 |

-40 |

-100 |

-50 |

-200 |

|

Thermal conductivity |

W/m•K |

0.2 |

0.25 |

0.60 |

0.60 |

0.25 |

0.24 |

|

Max.water absorption,23℃ |

K-1•10-5 |

7 |

9 |

4 |

5 |

10 |

12 |

|

Conductivity |

|||||||

|

Volume resisticity |

Ωcm |

>1012 |

>1013 |

<104 |

<105 |

>1013 |

>1015 |

|

Surface resisticity |

Ω |

>1015 |

>1011 |

<105 |

<103 |

>1012 |

>1015 |

![]()

EP PALSTIC BUSHING Series Specification Table

Metric Cylindrical Bushes

| Size and Specification table of straight sleeve series (for all sizes of different materials) | ||||

| model | d | tolerance | D | L |

| EP PLASTIC BUSHING-0304-03 | 3 | +0.014/+0.054 | 4.5 | 3 |

| EP PLASTIC BUSHING-0304-06 | 3 | +0.014/+0.054 | 4.5 | 6 |

| EP PLASTIC BUSHING-0305-05 | 3 | +0.014/+0.054 | 5.5 | 5 |

| EP PLASTIC BUSHING-0405-06 | 4 | +0.020/+0.068 | 5.5 | 6 |

| EP PLASTIC BUSHING-0406-06 | 4 | +0.020/+0.068 | 6 | 6 |

| EP PLASTIC BUSHING-0507-05 | 5 | +0.020/+0.068 | 7 | 5 |

| EP PLASTIC BUSHING-0507-08 | 5 | +0.020/+0.068 | 7 | 8 |

| EP PLASTIC BUSHING-0507-10 | 5 | +0.020/+0.068 | 7 | 10 |

| EP PLASTIC BUSHING-0507-18 | 5 | +0.020/+0.068 | 7 | 18 |

| EP PLASTIC BUSHING-0608-04 | 6 | +0.020/+0.068 | 8 | 4 |

| EP PLASTIC BUSHING-0608-06 | 6 | +0.020/+0.068 | 8 | 6 |

| EP PLASTIC BUSHING-0608-08 | 6 | +0.020/+0.068 | 8 | 8 |

| EP PLASTIC BUSHING-0608-10 | 6 | +0.020/+0.068 | 8 | 10 |

| EP PLASTIC BUSHING-0608-11 | 6 | +0.020/4-0.068 | 8 | 11 |

| EP PLASTIC BUSHING-0810-05 | 8 | +0.025/+0.083 | 10 | 5 |

| EP PLASTIC BUSHING-0810-06 | 8 | +0.025/4-0.083 | 10 | 6 |

| EP PLASTIC BUSHING-0810-08 | 8 | +0.025/+0.083 | 10 | 8 |

| EP PLASTIC BUSHING-0810-10 | 8 | +0.025/4-0.083 | 10 | 10 |

| EP PLASTIC BUSHING-0810-11 | 8 | +0.025/+0.083 | 10 | 11 |

| EP PLASTIC BUSHING-0810-12 | 8 | +0.025/+0.083 | 10 | 12 |

| EP PLASTIC BUSHING-0810-15 | 8 | +0.025/+0.083 | 10 | 15 |

| EP PLASTIC BUSHING-0811-10 | 8 | +0.025/+0.083 | 11 | 10 |

| EP PLASTIC BUSHING-0812-10 | 8 | +0.025/+0.083 | 12 | 10 |

| EP PLASTIC BUSHING-0911-06 | 9 | +0.025/4-0.083 | 11 | 6 |

| EP PLASTIC BUSHING-1012-04 | 10 | +0.025/+0.083 | 12 | 4 |

| EP PLASTIC BUSHING-1012-05 | 10 | +0.025/+0.083 | 12 | 5 |

| EP PLASTIC BUSHING-1012-06 | 10 | +0.025/+0.083 | 12 | 6 |

| EP PLASTIC BUSHING-1012-08 | 10 | +0.025/+0.083 | 12 | 8 |

| EP PLASTIC BUSHING-1012-10 | 10 | +0.025/+0.083 | 12 | 10 |

| EP PLASTIC BUSHING-1012-12 | 10 | +0.025/+0.083 | 12 | 12 |

| EP PLASTIC BUSHING-1012-15 | 10 | +0.025/+0.083 | 12 | 15 |

| EP PLASTIC BUSHING-1014-10 | 10 | +0.013/+0.071 | 14 | 10 |

| EP PLASTIC BUSHING-1014-16 | 10 | +0.025/+0.083 | 14 | 16 |

| EP PLASTIC BUSHING-1012-18 | 10 | +0.025/+0.083 | 12 | 18 |

| EP PLASTIC BUSHING-1012-20 | 10 | +0.025/+0.083 | 12 | 20 |

| EP PLASTIC BUSHING-1214-06 | 12 | +0.032/+0.102 | 14 | 6 |

| EP PLASTIC BUSHING-1214-08 | 12 | +0.032/+0.102 | 14 | 8 |

| EP PLASTIC BUSHING-1214-10 | 12 | +0.032/+0.102 | 14 | 10 |

| EP PLASTIC BUSHING-1214-12 | 12 | +0.032/+0.102 | 14 | 12 |

| EP PLASTIC BUSHING-1214-15 | 12 | +0.032/+0.102 | 14 | 15 |

| EP PLASTIC BUSHING-1214-20 | 12 | +0.032/+0.102 | 14 | 20 |

| Size and Specification table of straight sleeve series (for all sizes of different materials) | ||||

| model | id | tolerance | D | L |

| EP PLASTIC BUSHING-1820-20 | 18 | +0.032/+0.102 | 20 | 20 |

| EP PLASTIC BUSHING-1820-25 | 18 | +0.032/+0.102 | 20 | 25 |

| EP PLASTIC BUSHING-2022-12 | 20 | +0.040/+0.124 | 22 | 12 |

| EP PLASTIC BUSHING-2022-15 | 20 | +0.040/+0.124 | 22 | 15 |

| EP PLASTIC BUSHING-2022-28 | 20 | +0.040/+0.124 | 22 | 28 |

| EP PLASTIC BUSHING-2023-10 | 20 | +0.040/+0.124 | 23 | 10 |

| EP PLASTIC BUSHING-2023-15 | 20 | +0.040/+0J24 | 23 | 15 |

| EP PLASTIC BUSHING-2023-20 | 20 | +0.040/+0.124 | 23 | 20 |

| EP PLASTIC BUSHING-2023-23 | 20 | +0.040/+0.124 | 23 | 23 |

| EP PLASTIC BUSHING-2023-25 | 20 | +0.040/+0.124 | 23 | 25 |

| EP PLASTIC BUSHING-2023-30 | 20 | +0.040/+0.124 | 23 | 30 |

| EP PLASTIC BUSHING-2025-15S | 20 | +0.020/+0.104 | 25 | 15 |

| EP PLASTIC BUSHING-2125-32 | 21 | +0.040/+0.124 | 25 | 32 |

| EP PLASTIC BUSHING-2225-15 | 22 | +0.040/+0.124 | 25 | 15 |

| EP PLASTIC BUSHING-2225-20 | 22 | +0.040/+0.124 | 25 | 20 |

| EP PLASTIC BUSHING-2225-25 | 22 | +0.040/+0.124 | 25 | 25 |

| EP PLASTIC BUSHING-2225-30 | 22 | +0.040/+0J24 | 25 | 30 |

| EP PLASTIC BUSHING-2528-10 | 25 | +0.040/+0.124 | 28 | 10 |

| EP PLASTIC BUSHING-2528-12 | 25 | +0.040/+0.124 | 28 | 12 |

| EP PLASTIC BUSHING-2528-15 | 25 | +0.040/+0.124 | 28 | 15 |

| EP PLASTIC BUSHING-2528-20 | 25 | +0.040/+0.124 | 28 | 20 |

| EP PLASTIC BUSHING-2528-25 | 25 | +0.040/+0.124 | 28 | 25 |

| EP PLASTIC BUSHING-2528-30 | 25 | +0.040/+0.124 | 28 | 30 |

| EP PLASTIC BUSHING-2529-25 | 25 | +0.040/+0.124 | 29 | 25 |

| EP PLASTIC BUSHING-2530-25S | 25 | +0.020/+0.104 | 30 | 25 |

| EP PLASTIC BUSHING-2832-20 | 28 | +0.040/+0.124 | 32 | 20 |

| EP PLASTIC BUSHING-2832-25 | 28 | +0.040/+0J24 | 32 | 25 |

| EP PLASTIC BUSHING-2832-30 | 28 | +0.040/+0.124 | 32 | 30 |

| EP PLASTIC BUSHING-3034-20 | 30 | +0.040/+0.124 | 34 | 20 |

| EP PLASTIC BUSHING-3034-25 | 30 | +0.040/+0.124 | 34 | 25 |

| EP PLASTIC BUSHING-3034-30 | 30 | +0.040/+0.124 | 34 | 30 |

| EP PLASTIC BUSHING-3034-40 | 32 | +0.040/+0.124 | 34 | 40 |

| EP PLASTIC BUSHING 3236-20 | 32 | +0.050/+0.150 | 36 | 20 |

| EP PLASTIC BUSHING-3236-23 | 32 | +0.050/+0.150 | 36 | 23 |

| EP PLASTIC BUSHING-3236-25 | 32 | +0.050/+0.150 | 36 | 25 |

| EP PLASTIC BUSHING-3236-30 | 32 | +0.050/+0.150 | 36 | 30 |

| EP PLASTIC BUSHING-3236-40 | 32 | +0.050/+0J50 | 36 | 40 |

| EP PLASTIC BUSHING-3539-15 | 35 | +0.050/+0.150 | 39 | 15 |

| EP PLASTIC BUSHING-3539-20 | 35 | +0.050/+0.150 | 39 | 20 |

| EP PLASTIC BUSHING-3539-25 | 35 | +0.050/+0.150 | 39 | 25 |

| EP PLASTIC BUSHING-3539-30 | 35 | +0.050/+0.150 | 39 | 30 |

SELF-LUBRICATING BEARING

| Size and Specification table of straight sleeve series (for all sizes of different materials) | ||||

| EP PLASTIC BUSHING-1214-25 | 12 | +0.032/+0.102 | 14 | 25 |

| EP PLASTIC BUSHING-1215-20 | 12 | +0.032/+0.102 | 15 | 20 |

| EP PLASTIC BUSHING-1315-07 | 13 | +0.032/+0.102 | 15 | 7 |

| EP PLASTIC BUSHING-1315-10 | 13 | +0.032/+0.102 | 15 | 10 |

| EP PLASTIC BUSHING-1416-08 | 14 | +0.032/+0.102 | 16 | 8 |

| EP PLASTIC BUSHING-1416-10 | 14 | +0.032/+0.102 | 16 | 10 |

| EP PLASTIC BUSHING-1416-15 | 14 | +0.032/+0.102 | 16 | 15 |

| EP PLASTIC BUSHING-1416-20 | 14 | +0.032/+0.102 | 16 | 20 |

| EP PLASTIC BUSHING-1416-25 | 14 | +0.032/+0.102 | 16 | 25 |

| EP PLASTIC BUSHING-1517-10 | 15 | +0.032/+0.102 | 17 | 10 |

| EP PLASTIC BUSHING-1517-15 | 15 | +0.032/+0.102 | 17 | 15 |

| EP PLASTIC BUSHING-1517-17 | 15 | +0.032/+0.102 | 17 | 17 |

| EP PLASTIC BUSHING-1517-20 | 15 | +0.032/+0.102 | 17 | 20 |

| EP PLASTIC BUSHING-1517-25 | 15 | +0.032/+0.102 | 17 | 25 |

| EP PLASTIC BUSHING-1618-10 | 16 | +0.032/+0.102 | 18 | 10 |

| EP PLASTIC BUSHING-1618-12 | 16 | +0.032/+0.102 | 18 | 12 |

| EP PLASTIC BUSHING-1618-15 | 16 | +0.032/+0.102 | 18 | 15 |

| EP PLASTIC BUSHING-1618-20 | 16 | +0.032/+0.102 | 18 | 20 |

| EP PLASTIC BUSHING-1616-25 | 16 | +0.032/+0.102 | 18 | 25 |

| EP PLASTIC BUSHING-1620-16S | 16 | +0.016/+0.086 | 20 | 16 |

| EP PLASTIC BUSHING-1820-15 | 18 | +0.032/+0.102 | 20 | 15 |

| Size and Specification table of straight sleeve series (for all sizes of different materials) | ||||

| EP PLASTIC BUSHING-3539-40 | 35 | +0.050/+0.150 | 39 | 40 |

| EP PLASTIC BUSHING-359-50 | 35 | +0.050/+0.150 | 39 | 50 |

| EP PLASTIC BUSHING-4044-20 | 40 | +0.050/+0.150 | 44 | 20 |

| EP PLASTIC BUSHING-4044-30 | 40 | +0.050/+0.150 | 44 | 30 |

| EP PLASTIC BUSHING-4044-40 | 40 | +0.050/+0.150 | 44 | 40 |

| EP PLASTIC BUSHING-4044-50 | 40 | +0.050/+0.150 | 44 | 50 |

| EP PLASTIC BUSHING-4550-30 | 45 | +0.050/+0.150 | 50 | 30 |

| EP PLASTIC BUSHING-4550-40 | 45 | +0.025/+0.125 | 50 | 40 |

| EP PLASTIC BUSHING-4550-50 | 45 | +0.050/+0.150 | 50 | 50 |

| EP PLASTIC BUSHING-5055-20 | 50 | +0.050/+0.150 | 55 | 20 |

| EP PLASTIC BUSHING-5055-30 | 50 | +0.050/+0.150 | 55 | 30 |

| EP PLASTIC BUSHING-5055-40 | 50 | +0.050/+0.150 | 55 | 40 |

| EP PLASTIC BUSHING-5055-50 | 50 | +0.050/+0.150 | 55 | 50 |

| EP PLASTIC BUSHING-8590-40 | 85 | +0.036/+0.176 | 90 | 40 |

•Tolerance drafter being pressed into housing H7(ISO3547-1)

Recommend fitting tolerance

Housing: H7

Shaft: H9