|

|

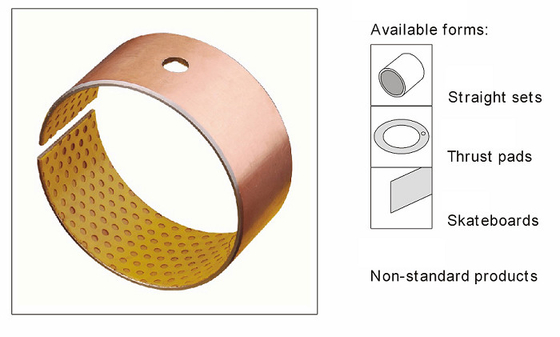

| Brand Name: | Straight Sleeve Bore Bushings |

| Model Number: | sleeve Bushing Applications include valves, commercial fire sprinkler systems, mixers, blenders, swivels, and extruders. |

| MOQ: | 100 Piece/Pieces (Min. Order) |

| Price: | Negotiable |

| Payment Terms: | TT IN ADVANCE |

| Supply Ability: | Valve Split Steel Bushings Shaft Bearings Suppliers |

When specifying sleeve bushings for gate, globe, and check valves, it is crucial to consider the appropriate size and material to ensure optimal performance and durability. (Polytetrafluoroethylene), also known as ptfe, is a commonly used coating material for valve bushings due to its excellent properties such as low friction, chemical resistance, and temperature tolerance.

The sleeve bushing size should be determined based on the specific valve dimensions and operating conditions. It is essential to ensure that the bushing fits tightly within the valve body to prevent leakage and wear. The coating provides an additional layer of protection and lubrication, reducing friction and wear on the bushing surface.

For gate, globe, and check valves, the sleeve bushing size typically corresponds to the valve's seat diameter or valve trim size. Manufacturers often provide standard bushing sizes for different valve sizes and types, but custom sizes can also be fabricated to meet specific requirements.

When selecting a -coated sleeve bushing, it is important to consider the coating thickness and quality. A thicker coating may provide better protection but can also increase the overall size of the bushing. The coating should be evenly applied and free of defects to ensure maximum durability and performance.

In summary, when specifying sleeve bushings for gate, globe, and check valves with coating, it is essential to consider the valve size, operating conditions, and coating requirements to ensure a reliable and long-lasting solution.

Max. load |

Static |

250N/mm2 |

Dynamic |

140N/mm2 |

|

Max. speed |

Dry |

2m/s |

Lubrication |

>2m/s |

|

Max. PV (Dry) |

Short-time |

3.6N/mm2*·m/s |

Continuous |

1.8N/mm2*·m/s |

|

Temp. |

-195℃~+280℃ |

|

Friction coefficient |

0.03~0.20 |

|

Thermal conductivity |

42W (m·k)-1 |

|

Coefficient of thermal expansion |

11*10-6k-1 |

|

![]()