-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

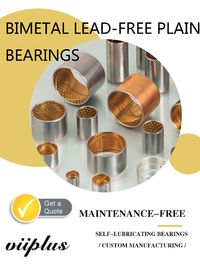

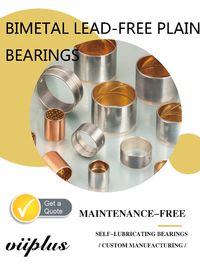

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

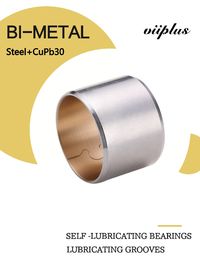

Connecting Rod Bimetal Sleeve Bushes Steel CuPb30 with Lubricating Grooves 700

| Place of Origin | Bimetal Bearing Manufacturers |

|---|---|

| Brand Name | bimetal SAE-797 SAE 48 SAE-799 bushings |

| Certification | Bimetal Bush Material CuPb10Sn10、CuPb6Sn6Zn3 CuPb24Sn4... |

| Model Number | JF800 JF720 JF700 Bimetal Lead-Free Plain Bearings |

| Minimum Order Quantity | 800 Piece/Pieces (Min. Order) |

| Price | $0.20 - $2.00 / Pieces ,Negotiable |

| Packaging Details | export & import bimetal bushings International carton standard |

| Delivery Time | Manufacture Bimetal Bushing In Stock, Delivered Within Days. |

| Payment Terms | TT IN ADVANCE Western Union |

| Supply Ability | casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Long Life, Dry, Low Resistance, Maintenance Free | Meterial | Low Carbon Steel Wth Tin-Lead-Bronze Alloy (CuSn10Pb10) |

|---|---|---|---|

| Finishing | Tin Plating, Cooper Plating | Type | Sleeve Bushing,Wrapped Bushes With Flange,Strips |

| Application | Bi-metallic Composite Bearings,Engine, Bearing, Trailer Pump, Automobile, Auto Engine Parts | Standard | SAE 797, SAE 799, SAE 783, SAE 48, SAE 49 Bronze Alloy Bearing |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Steel Backed Bronze Bushing, Bimetallic Bushes | Bimetallic Bearing Bushing | Bimetal Bearing With Steel Backing And Bronze Overlay • Particularly Suitable For High ... Bimetal Plain Bearings To Standard SAE 792 |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | bimetal bush,bimetal bearings |

||

Bimetal Bearing Bushes

About VIIPLUS We Are Supplier Of Bimetal Bushing Parts For Connecting Rod & Camshaft Bushes With High Quality Unebatable Pricing And Customer Value.Bi-metal Bearings_SAE 797, SAE 799, SAE 783, SAE 48, SAE 49 Bi-metallic composite bearings to high-quality low-carbon steel substrate, the surface of the sintered copper alloy with low friction characteristics (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as bearing wear layer ......The sleeve steel bronze bushings & bearings-700 bearings made to order from china are bimetal sliding bearings with a steel strip and sintered CuPb30 as the surface sliding layer. These sliding bearings have good anti-locking protection and a high proportion of lead, meaning that they can bind more dirt particles and impurities, thereby preventing a seize-up.

bimetal bearing is made of steel sintered with CuPb10Sn10 or CuSn6Zn6Pb3 as a lining layer.This type of bushing show its best performance among bushings made of Cu-lead alloy material in this product range.It suits most for middle speed and high impact conditions.Its application including balance suspensions of heavy-duty trucks, track roller of bulldozers,auto chassis etc.

| Lead bronze alloy | CuPb10Sn10 or CuSn6Zn6Pb3 | ||

| Load capacity | 65N/mm² | Harderness alloy | HB70~100 |

| Temperature Max | 260℃ | ||

Bimetal Sleeve Bushing consists of a high quality low carbon steel backing carring a sintered tin-lead-bronze alloy (CuPb30) as a sliding layer. In order to improve tribological behavior the sliding layer can be machined with lubricating grooves for oil- or grease storage and distribution. In case of corrosive environment the backing can be copper plated. bimetal sleeve bushings is used for wrapped bushes, thrust washers and bushes in connecting rods of gas engines, etc.

Plain Bimetal Bearings Typically Used In Truck Trunnon Shaft, King Pin Kit, Connection Rod, Rocker Arm, Leaf Spring, Cam Shaft, Crankshaft, Bulldozer And Excavator Track Roller, Carrier Roller, Idler Etc.

Bi-metallic composite bearings lead bronze or lead-free Bimetal wrapped cylindrical bushings ( DIN 1494 )

Sliding layer can be machined with lubricating grooves and/or with grease indents

Steel backing can be copper plated

Steel+CuPb30

Bimetal self-lubricating bearings reduce noise and stickiness.In addition, its matching shaft material reduces wear and extends service life.The VIIPLUS solution is the same size as copper bearings, but reduces the need for expensive improvements and retrofits.

Bimetal Bushing & Bearings Services. Description: sliding bearings. Bimetal wrapped cylindrical bushings ( DIN 1494 )

VIIPLUS bimetal bearings take steel backing as base The

bearings are sintered with CuPb10Sn10, CuPb24Sn4,CuPb30, CuSn6Zn6Pb3 or AlSn20Cu after press. It can insure the bearings O.D. Precision against the friction between O.D. And housing after pressing it into housing because of mild steel as its base. The chemical changes of inner alloy layer can make the bearings work well under various load presses, different working temperatures and sliding speeds. Different structures of oil grooves and oil Indentations can satisfy different adding oil ways andprevent the bearings from gripping shaft.

The structural characteristics

Bimetal composite bearings with high quality low carbon steel as substrate, the surface of the sinter with low friction properties of copper alloy (CuPb10Sn10 CuPb6Sn6Zn3 CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as wear-resisting layer of bearing, can need according to the operating conditions of copper alloy surface processing of various types of oil tank, oil hole, hole, etc., in order to suit to cannot continue to go hard or go occasion.Good joint strength and optimum bearing capacity can be obtained by the secondary sintering and extrusion.

Description

Bimetallic self-lubricating bearing (foreign says deva. Bm) is a high quality low carbon steel, bronze sheet or stainless steel plate as substrate, spherical bronze powder as middle transition layer on the surface, at the same time to sintering rolling with solid lubricant (graphite) copper alloy as friction surface layer of a kind of self-lubricating composite bearing material, the rolling and sliding bearing.The material has the advantages of self-lubrication, high bearing capacity, good anti-friction and wear-resisting performance, applicable temperature, wide range of medium, simple structure, compact size, and can work in the condition of non-oil lubrication for a long time.

Bi-metallic composite bearing material consists of steel backing with lead bronze or lead-free copper alloy

Structure Characteristics

Bronze Gleitlager Viiplus Bearing Bi-metallic composite bearing material consists of steel backing with lead bronze or lead-free copper alloy(CuPb10Sn10,CuPb6Sn6Zn3,CuPb24Sn4,CuPb30,AlSn20Cu)lining, bearing material for oil/grease lubricatedapplications. The copper alloy forms a continuously frame for thermal conductivity. These bearing structures are with high load capacity and good fatigue property. Higher tolerance can be achieved after re-machined from the customers. Lead-freebronze lining bearing material conforms to the European RoHS directive.

Application

Angineering machine: underpan, thrust wheel, Towing wheel, Steering knuckle,tension pulley...Automotive:trunnion shaft, connecting rod, valve rocker, camshaft, gear box, internal-combustion engine,And Plunger pump friction plate, gear pump friction plate...

According to the different working conditions, different alloy material (CuPb10Sn10,CuPb6Sn6Zn3,CuPb24Sn4,CuPb30,AlSn20Cu,CuSn8Ni)can be sintered on steel backing.-

Bimetal Bearings Strips, Slide paths Sliding Plate Bimetallic strip Materials

Bimetal Bearings

Low Carbon Steel Bi Metal Bearings Tin - Lead - Bronze Alloy For Transmission Gear Box

Steel shell backed with a lead bronze lining bearing material for oil lubricated applications. This material has high load capacity and good fatigue properties, it is widely used in automotive applications such as compressors

For Transmission Gear Box

Characteristics

VSB-80 Bimetallic composite bearings

Steel shell backed with a lead bronze lining bearing material for oil lubricated applications. This material has high load capacity and good fatigue properties. It is widely used in automotive applications such as compressors, steering gear, power steering, pedal bearings, king-pin bushes, tailgate pivots, mechanical handling and lifting equipment, hydraulic motors, agricultural machinery etc.

· Bimetal bearing with steel backing and bronze overlay

· Particularly suitable for high specific loads with oscillating motion and low frequency

· Applicable in rough operation conditions

· High load capacity, very good resistance to fatigue strength at higher temperatures

Strusture

1.Sintered bronze lazer: God wear resistance and excellent load carrying capacity.

2.Steel backing:Setting the foundation of the bushings,the steel back provides exceptional stability, load carrying and heat dissipation characteristics.

Technical Data

Structure And Composition

Steel Backing and Leaded Bronze Overlay

Steel + CuPb10Sn10 with indents

MICROSECTION

|

|

Sliding layer with |

|

OPERATING PERFORMANCE |

|

|

Dry |

Poor |

|

Oil lubricated |

Good |

|

Grease lubricated |

Very Good |

|

Water lubricated |

Poor |

|

Process fluid lubricated |

Poor |

Alloy Chemical Compositions

|

Content |

Cu |

Pb |

Sn |

Zn |

P |

Fe |

Ni |

Sb |

Others |

|

Remainder |

9-11 |

9-11 |

0.5 |

0.1 |

0.7 |

0.5 |

0.2 |

0.5 |

Availability

Bearing forms available in standard dimensions

· Cylindrical bushes

· Thrust washers

Bearing forms made to order: cylindrical bushes and thrust washers with non-standard dimensions, sliding plates, customized bearing designs

Typical Applications

Construction machinery: chassis travelling mechanism supporting wheel shaft sleeve, towing wheel shaft sleeve, tensioning wheel shaft sleeve;

Automobile industry: balance shaft bushing, steel plate pin bushing, steering knuckle main shaw shaft sleeve, connecting rod shaft sleeve, valve rocker shaft sleeve, camshaft shaft sleeve, differential shaft sleeve, transmission shaft sleeve, internal combustion engine spindle bush, thrust washer;And piston pump side piece, gear pump side piece and so on.

In practical application, different grades of alloy can be sintered on the surface according to different working conditions.

This material is recommended to be used under the medium speed and medium load condition with oil or grease lubricating. It is widely used for motor rod ends, Kingpin bushing, undercarriage rollers, hydraulic cylinder rod eyes of construction machines and spherical joint bearings of agricultural machines. Because this material is with lead, the specific parts are not allowed to be used according to certain laws or regulations.

Bimetal Bushings Size

START YOUR PROJECT WITH AN APPLICATION ENGINEER

Sliding Bearing, Bimetal Bush, Wrapped Bronze Bushing, Oiles Bush, Oiles Bearing, Supplier China, High Quality

Bushings,Lubricated Bearings,Composite Bearings,Metal Bearings,Compressor Bearings,Metal-polymer,Filament Wound,Plain Bearings,Flange Bearings,Polymer Bearings,Flange Bushings,Pump Bearings,Flanged Bushes,Thrust Plates,Industrial Bearings.![]()

FOLLOW US ON

![]()

HTTP://WWW.BRONZEGLEITLAGER.COM