-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Slide Paths PAS Bronze Bushing Material Metric Sleeve Bearings Strips Plate

| Place of Origin | Plain Bearing Material |

|---|---|

| Brand Name | China Plain-Bearing |

| Certification | DIN 1494/ISO 3547 |

| Model Number | Wrapped composite sliding bearing |

| Minimum Order Quantity | 500 Piece/Pieces |

| Price | flat strip material inch sizes Manufacturers,Factory Price |

| Packaging Details | Shipment Bushing Packing: Cartons per Wooden Case or Pallet. |

| Delivery Time | 15~20 Days |

| Payment Terms | TT IN ADVANCE |

| Supply Ability | 1000000 Piece/Pieces per Month Plain-Bearing Bushing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Low-maintenance, Lubricated Applications | Meterial | Steel + Porous Bronze + PTFE Strips |

|---|---|---|---|

| Plating | Tin Or Copper | Type | Wrapped Bushes, Flanged Bearing, Thrust Washer |

| Finishing | Tin Plated, Brass Plated | Special Use | High-strength Steel Plate |

| Application | Printing And Dyeing Machines, And Machines Used In The Ocean Industry, Etc. | Lubricating | Oilless |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | du strip,self lubricating bearing strip,PAS Bronze Bushing Material |

||

Self-lubricating steel backed du bushing bearings combine the advantages of many conventional lubricated metal plain bearings - especially high load capacities and dimensional stiffness - with the design freedom of self-lubricating materials, including the ability to perform well beyond conventional lubricants.

Custom Solutions for Demanding Technical Requirements

We work closely with our customers to develop new self-lubricating bronze bushings solutions that are then added to our list of catalog bronze bushing products.

Self-Lubricating Bronze Bushing, Steel Backed DU Plain Bearing

Garlock Bearings Replacement sleeve

Discovery DU bushing bearing, relating to plain bearings and self-lubricating bushings material and bushing price ...

Plain-Bearing - Bore size, OD size, Length size, PTFE Material

80160/ DU Plain Bearing - ID=242, OD=247, Length=100mm

80161/ DU Plain Bearing - ID=300, OD=305, Length=100mm

![]()

VIIPLUS SLIDING BEARING Our range offered SME includes Metal Bushing, Steel Sleeve BushingThrust Washer, Bronze Graphite Plate, Valve Gearbox Bushings, and more. Besides these, we are also rendering Metal Coating Self-lubricating bearing Strips, Material Export Service and more.

Plain bearing materials Plain bearing Strips, Slide paths PAS Strips Material in detail DU Strip Metric Streifen, Gleitbahnen | VSB-10

Impregnated with our own proprietary lubricant, these bushings are composed of PTFE and special material uniformly dispersed within polyacetal plastic resin, a plastic material offering excellent bearing characteristics.

VSB-10 Strips, Slide paths PAS

For all the global industry

Provide high-quality self-lubricating products

Characteristics

VSB-10 Streifen, Gleitbahnen PAS

of shapes.

Table of Contents

Material information

Plain bearing production

Characteristics: maintenance-free and robust

Material composition

Models and tables of dimensions

More information

Plain bearing Bearing Material DU production

Standard designs are:

-

Cylindrical bushes

-

Collar bushes

Thrust washers PAW..

-

Thrust washers

-

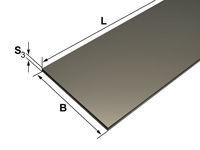

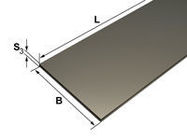

Strips

Characteristics of VSB-10 strips material

-

Very low stick-slip tendency

-

Low wear

-

Good chemical resistance

-

Low friction value

-

No tendency to weld to metal

-

Extremely swell-resistant

-

Does not absorb water

Preferred areas of application

-

Maintenance-free operation under dry-running conditions

-

Rotating or oscillating movements

-

Up to a velocity of 2 m/s

-

Linear movements

-

Temperature range -200 °C to 280 °C

Material composition

Strips Material composition

-

1. Running-in layer

PTFE matrix with bulking agent¹

Layer thickness [mm]:

max. 0.03

2. Sliding layer

Tin-lead-bronze

Layer thickness [mm]:

0.20–0.35

Pore volume [%]:

approx. 30

3. Bearing back

Steel

Steel thickness [mm]:

Variable

Steel hardness [HB]:

100–180

1 The pores of the sliding layer are also filled with this lubricant mass.

Models and tables of dimensions

with steel back, maintenance-free

If these material sections are used to create slide paths, they have the following main functions:

-

Absorbing and transferring forces acting vertically to the running surface

-

Fixing moving components to each other

-

Ensuring guidance accuracy for axial movements over the entire service life

Strips are available in two material groups:

-

Material group P1 for maintenance-free, dry-running applications

-

Material group P2 for low-maintenance, lubricated applications

VSB-10 Steel + Bronze Powder + PTFE/Fibre(DU) Bushings

· Bushing material suitable for lubricated applications

· self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

· Anti-friction bearing suitable for linear, oscillating and rotating movements

Material is designed to operate without supplemental lubrication and will perform excellent when lubrication is present. Low friction, low wear rate, good sliding characteristics and very low absorption are a few of the features of this material. VSB-10 bushings will support rotary, linear and oscillating motion.

Strusture

1. PTFE/Fibre mixture thickness 0.01~0.03mm. It is the contact surface for the rotating shaft. Minute partides of the PTFE layer and the sintered bronze material combine to create a solid lubricant film, which coats the shaft.

2. Sintered bronze powder thickness 0.20*0.35mm,A special composition of powdered copper is thermally fused to the steel backing. This contact layer acts as an anchor for the PTFE layer and conducts the thermal build up away from the bearing surfaces.

3. Low-carbon steel backing. Setting the foundation of the bushings, the steel back provides exceptional stability, load carrying and heat dissipation characteristics.

Technical Data

Structure And Composition

· Metal-Polymer Composite Self-lubricating Bushing Material

· Steel Back + Porous Bronze Sinter +

· PTFE + Lead

Microsection

|

|

Sliding layer |

|

OPERATING PERFORMANCE |

|

|

Dry |

Very Good |

|

Oil lubricated |

Good |

|

Grease lubricated |

Fair |

|

Water lubricated |

Fair |

|

Process fluid lubricated |

Fai |

Bearing Properties

|

GENERAL |

|

Unit |

Value |

|---|---|---|---|

|

Maximum load, p |

Static |

N/mm2 |

250 |

|

Operating temperature |

Min |

°C |

- 195 |

|

Coefficient of linear thermal expansion |

Parallel to the surface |

10-6/K |

11 |

|

Normal to the surface |

10-6/K |

30 |

|

DRY |

|

|

|

|

Maximum sliding speed, U |

|

m/s |

|

|

Coefficient of friction |

|

|

0.03 - 0.20 * |

|

OIL LUBRICATED |

|

|

|

|

Maximum sliding speed, U |

|

m/s |

|

* Depending on operating conditions

Technical data

|

Max. load |

Static |

250N/mm2 |

|

Dynamic |

140N/mm2 |

|

|

Max. speed |

Dry |

2m/s |

|

Lubrication |

>2m/s |

|

|

Max. PV (Dry) |

Short-time |

3.6N/mm2*·m/s |

|

Continuous |

1.8N/mm2*·m/s |

|

|

Temp. |

-195℃~+280℃ |

|

|

Friction coefficient |

0.03~0.20 |

|

|

Thermal conductivity |

42W (m·k)-1 |

|

|

Coefficient of thermal expansion |

11*10-6k-1 |

|

Availability

Bearing forms available in standard dimensions

- Cylindrical bushes

- Flanged bushes

- Thrust washers

- Flanged washers

- Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping or deep drawing, customized bushing designs

Typical Applications

This material meets the demanding criteria for long life and maintenance free performance with or without lubrication.

Automotive: tractors, combines, crop sprayers, earth-movers, graders and other construction, auto machines, specific uses in power steering cylinders, steering gear thrust washers, disc brakes, calipers and pistons, shock absorbers, governor linkage, windshield wiper motor, tilt gear assemblies...

Business machines: photocopy machines, typewriters, mail sorters, postage meter systems, computer terminal printers and peripheral equipment, automatic printing devices, mail processing machinery...

Hydraulics and valves: pumps including gear, rotary, water, axial piston, and other types, ball, butterfly, poppet steam, and other valves and valve trunnions...

Home appliances: tape recorders, refrigerators, air conditioners, cleaners, polishers, sewing machines, ovens, dishwashers, clothes washing machines...And materials handling, marine engine, packaging, textile equipment, tools...etc.

Self-lubricating Composite Bushing - Metric Size

| Product | Bearing Type | Shaft Dia., Nominal (d) (mm) | Bearing Outside Diameter, Nominal(Do) (mm) | Bearing Length, Nominal (B) (mm) | Wall Thickness (S3) (mm) |

| du bushing 0606 | straight | 6 | 8 | 6 | 1.01 |

| du bushing 0608 | straight | 6 | 8 | 8 | 1.01 |

| du bushing 0610 | straight | 6 | 8 | 10 | 1.01 |

| du bushing 0806 | straight | 8 | 10 | 6 | 1.01 |

| du bushing 0808 | straight | 8 | 10 | 8 | 1.01 |

| du bushing 0810 | straight | 8 | 10 | 10 | 1.01 |

| du bushing 0812 | straight | 8 | 10 | 12 | 1.01 |

| du bushing 0815 | straight | 8 | 10 | 15 | 1.01 |

| du bushing 1006 | straight | 10 | 12 | 6 | 1.01 |

| du bushing 1008 | straight | 10 | 12 | 8 | 1.01 |

| du bushing 1010 | straight | 10 | 12 | 10 | 1.01 |

| du bushing 1012 | straight | 10 | 12 | 12 | 1.01 |

| du bushing 1015 | straight | 10 | 12 | 15 | 1.01 |

| du bushing 1020 | straight | 10 | 12 | 20 | 1.01 |

| du bushing 1206 | straight | 12 | 14 | 6 | 1.01 |

| du bushing 1208 | straight | 12 | 14 | 8 | 1.01 |

| du bushing 1210 | straight | 12 | 14 | 10 | 1.01 |

| du bushing 1212 | straight | 12 | 14 | 12 | 1.01 |

| du bushing 1215 | straight | 12 | 14 | 15 | 1.01 |

| du bushing 1220 | straight | 12 | 14 | 20 | 1.01 |

| du bushing 1225 | straight | 12 | 14 | 25 | 1.01 |

| du bushing 1310 | straight | 13 | 15 | 10 | 1.01 |

| du bushing 1320 | straight | 13 | 15 | 20 | 1.01 |

| du bushing 1410 | straight | 14 | 16 | 10 | 1.01 |

| du bushing 1412 | straight | 14 | 16 | 12 | 1.01 |

| du bushing 1415 | straight | 14 | 16 | 15 | 1.01 |

| du bushing 1420 | straight | 14 | 16 | 20 | 1.01 |

| du bushing 1425 | straight | 14 | 16 | 25 | 1.01 |

| du bushing 1510 | straight | 15 | 17 | 10 | 1.01 |

| du bushing 1512 | straight | 15 | 17 | 12 | 1.01 |

| du bushing 1515 | straight | 15 | 17 | 15 | 1.01 |

| du bushing 1520 | straight | 15 | 17 | 20 | 1.01 |

| du bushing 1525 | straight | 15 | 17 | 25 | 1.01 |

| du bushing 1610 | straight | 16 | 18 | 10 | 1.01 |

| du bushing 1612 | straight | 16 | 18 | 12 | 1.01 |

| du bushing 1615 | straight | 16 | 18 | 15 | 1.01 |

| du bushing 1620 | straight | 16 | 18 | 20 | 1.01 |

| du bushing 1625 | straight | 16 | 18 | 25 | 1.01 |

| du bushing 1710 | straight | 17 | 19 | 10 | 1.01 |

| du bushing 1712 | straight | 17 | 19 | 12 | 1.01 |

| du bushing 1720 | straight | 17 | 19 | 20 | 1.01 |

| du bushing 1810 | straight | 18 | 20 | 10 | 1.01 |

| du bushing 1812 | straight | 18 | 20 | 12 | 1.01 |

| du bushing 1815 | straight | 18 | 20 | 15 | 1.01 |

| du bushing 1820 | straight | 18 | 20 | 20 | 1.01 |

| du bushing 1825 | straight | 18 | 20 | 25 | 1.01 |

| du bushing 2010 | straight | 20 | 23 | 10 | 1.51 |

| du bushing 2012 | straight | 20 | 23 | 12 | 1.51 |

| du bushing 2015 | straight | 20 | 23 | 15 | 1.51 |

| du bushing 2020 | straight | 20 | 23 | 20 | 1.51 |

| du bushing 2025 | straight | 20 | 23 | 25 | 1.51 |

| du bushing 2030 | straight | 20 | 23 | 30 | 1.51 |

| du bushing 2210 | straight | 22 | 25 | 10 | 1.51 |

| du bushing 2212 | straight | 22 | 25 | 12 | 1.51 |

| du bushing 2215 | straight | 22 | 25 | 15 | 1.51 |

| du bushing 2220 | straight | 22 | 25 | 20 | 1.51 |

| du bushing 2225 | straight | 22 | 25 | 25 | 1.51 |

| du bushing 2230 | straight | 22 | 25 | 30 | 1.51 |

| du bushing 2415 | straight | 24 | 27 | 15 | 1.51 |

| du bushing 2420 | straight | 24 | 27 | 20 | 1.51 |

| du bushing 2425 | straight | 24 | 27 | 25 | 1.51 |

| du bushing 2430 | straight | 24 | 27 | 30 | 1.51 |

| du bushing 2510 | straight | 25 | 28 | 10 | 1.51 |

| du bushing 2512 | straight | 25 | 28 | 12 | 1.51 |

| du bushing 2515 | straight | 25 | 28 | 15 | 1.51 |

| du bushing 2520 | straight | 25 | 28 | 20 | 1.51 |

| du bushing 2525 | straight | 25 | 28 | 25 | 1.51 |

| du bushing 2530 | straight | 25 | 28 | 30 | 1.51 |

| du bushing 2540 | straight | 25 | 28 | 40 | 1.51 |

| du bushing 2550 | straight | 25 | 28 | 50 | 1.51 |

| du bushing 2815 | straight | 28 | 32 | 15 | 2.01 |

| du bushing 2820 | straight | 28 | 32 | 20 | 2.01 |

| du bushing 2825 | straight | 28 | 32 | 25 | 2.01 |

| du bushing 2830 | straight | 28 | 32 | 30 | 2.01 |

| du bushing 2840 | straight | 28 | 32 | 40 | 2.01 |

| du bushing 3012 | straight | 30 | 34 | 12 | 2.01 |

| du bushing 3015 | straight | 30 | 34 | 15 | 2.01 |

| du bushing 3020 | straight | 30 | 34 | 20 | 2.01 |

| du bushing 3025 | straight | 30 | 34 | 25 | 2.01 |

| du bushing 3030 | straight | 30 | 34 | 30 | 2.01 |

| du bushing 3040 | straight | 30 | 34 | 40 | 2.01 |

| du bushing 3220 | straight | 32 | 36 | 20 | 2.01 |

| du bushing 3230 | straight | 32 | 36 | 30 | 2.01 |

| du bushing 3240 | straight | 32 | 36 | 40 | 2.01 |

| du bushing 3512 | straight | 35 | 39 | 12 | 2.01 |

| du bushing 3515 | straight | 35 | 39 | 15 | 2.01 |

| du bushing 3520 | straight | 35 | 39 | 20 | 2.01 |

| du bushing 3525 | straight | 35 | 39 | 25 | 2.01 |

| du bushing 3530 | straight | 35 | 39 | 30 | 2.01 |

| du bushing 3540 | straight | 35 | 39 | 40 | 2.01 |

| du bushing 3550 | straight | 35 | 39 | 50 | 2.01 |

| du bushing 3815 | straight | 38 | 42 | 15 | 2.01 |

| du bushing 3830 | straight | 38 | 42 | 30 | 2.01 |

| du bushing 3840 | straight | 38 | 42 | 40 | 2.01 |

| du bushing 4012 | straight | 40 | 44 | 12 | 2.01 |

| du bushing 4020 | straight | 40 | 44 | 20 | 2.01 |

| du bushing 4025 | straight | 40 | 44 | 25 | 2.01 |

| du bushing 4030 | straight | 40 | 44 | 30 | 2.01 |

| du bushing 4040 | straight | 40 | 44 | 40 | 2.01 |

| du bushing 4050 | straight | 40 | 44 | 50 | 2.01 |

| du bushing 4520 | straight | 45 | 50 | 20 | 2.51 |

| du bushing 4525 | straight | 45 | 50 | 25 | 2.51 |

| du bushing 4530 | straight | 45 | 50 | 30 | 2.51 |

| du bushing 4540 | straight | 45 | 50 | 40 | 2.51 |

| du bushing 4550 | straight | 45 | 50 | 50 | 2.51 |

| du bushing 5020 | straight | 50 | 55 | 20 | 2.51 |

| du bushing 5030 | straight | 50 | 55 | 30 | 2.51 |

| du bushing 5040 | straight | 50 | 55 | 40 | 2.51 |

| du bushing 5050 | straight | 50 | 55 | 50 | 2.51 |

| du bushing 5060 | straight | 50 | 55 | 60 | 2.51 |

| du bushing 5530 | straight | 55 | 60 | 30 | 2.51 |

| du bushing 5540 | straight | 55 | 60 | 40 | 2.51 |

| du bushing 5550 | straight | 55 | 60 | 50 | 2.51 |

| du bushing 5560 | straight | 55 | 60 | 60 | 2.51 |

| du bushing 6030 | straight | 60 | 65 | 30 | 2.51 |

| du bushing 6040 | straight | 60 | 65 | 40 | 2.51 |

| du bushing 6050 | straight | 60 | 65 | 50 | 2.51 |

| du bushing 6060 | straight | 60 | 65 | 60 | 2.51 |

| du bushing 6070 | straight | 60 | 65 | 70 | 2.51 |

| du bushing 6530 | straight | 65 | 70 | 30 | 2.51 |

| du bushing 6540 | straight | 65 | 70 | 40 | 2.51 |

| du bushing 6550 | straight | 65 | 70 | 50 | 2.51 |

| du bushing 6560 | straight | 65 | 70 | 60 | 2.51 |

| du bushing 6570 | straight | 65 | 70 | 70 | 2.51 |

| du bushing 7040 | straight | 70 | 75 | 40 | 2.51 |

| du bushing 7050 | straight | 70 | 75 | 50 | 2.51 |

| du bushing 7060 | straight | 70 | 75 | 60 | 2.51 |

| du bushing 7070 | straight | 70 | 75 | 70 | 2.51 |

| du bushing 7080 | straight | 70 | 75 | 80 | 2.51 |

| du bushing 7530 | straight | 75 | 80 | 30 | 2.51 |

| du bushing 7540 | straight | 75 | 80 | 40 | 2.51 |

| du bushing 7550 | straight | 75 | 80 | 50 | 2.51 |

| du bushing 7560 | straight | 75 | 80 | 60 | 2.51 |

| du bushing 7570 | straight | 75 | 80 | 70 | 2.51 |

| du bushing 7580 | straight | 75 | 80 | 80 | 2.51 |

| du bushing 8040 | straight | 80 | 85 | 40 | 2.49 |

| du bushing 8050 | straight | 80 | 85 | 50 | 2.49 |

| du bushing 8060 | straight | 80 | 85 | 60 | 2.49 |

| du bushing 8070 | straight | 80 | 85 | 70 | 2.49 |

| du bushing 8080 | straight | 80 | 85 | 80 | 2.49 |

| du bushing 80100 | straight | 80 | 85 | 100 | 2.49 |

| du bushing 8540 | straight | 85 | 90 | 40 | 2.49 |

| du bushing 8560 | straight | 85 | 90 | 60 | 2.49 |

| du bushing 8580 | straight | 85 | 90 | 80 | 2.49 |

| du bushing 85100 | straight | 85 | 90 | 100 | 2.49 |

| du bushing 9040 | straight | 90 | 95 | 40 | 2.49 |

| du bushing 9050 | straight | 90 | 95 | 50 | 2.49 |

| du bushing 9060 | straight | 90 | 95 | 60 | 2.49 |

| du bushing 9080 | straight | 90 | 95 | 80 | 2.49 |

| du bushing 90100 | straight | 90 | 95 | 100 | 2.49 |

| du bushing 9550 | straight | 95 | 100 | 50 | 2.49 |

| du bushing 9560 | straight | 95 | 100 | 60 | 2.49 |

| du bushing 9580 | straight | 95 | 100 | 80 | 2.49 |

| du bushing 95100 | straight | 95 | 100 | 100 | 2.49 |

| du bushing 10050 | straight | 100 | 105 | 50 | 2.49 |

| du bushing 10060 | straight | 100 | 105 | 60 | 2.49 |

| du bushing 10080 | straight | 100 | 105 | 80 | 2.49 |

| du bushing 100115 | straight | 100 | 105 | 115 | 2.49 |

| du bushing 10560 | straight | 105 | 110 | 60 | 2.49 |

| du bushing 10580 | straight | 105 | 110 | 80 | 2.49 |

| du bushing 105115 | straight | 105 | 110 | 115 | 2.49 |

| du bushing 11060 | straight | 110 | 115 | 60 | 2.49 |

| du bushing 11080 | straight | 110 | 115 | 80 | 2.49 |

| du bushing 110115 | straight | 110 | 115 | 115 | 2.49 |

| du bushing 12060 | straight | 120 | 125 | 60 | 2.47 |

| du bushing 12080 | straight | 120 | 125 | 80 | 2.47 |

| du bushing 120100 | straight | 120 | 125 | 100 | 2.47 |

| du bushing 12560 | straight | 125 | 130 | 60 | 2.47 |

| du bushing 125100 | straight | 125 | 130 | 2.47 | |

| du bushing 125115 | straight | 125 | 130 | 115 | 2.47 |

| du bushing 13060 | straight | 130 | 135 | 60 | 2.47 |

| du bushing 13080 | straight | 130 | 135 | 80 | 2.47 |

| du bushing 130100 | straight | 130 | 135 | 100 | 2.47 |

| du bushing 14060 | straight | 140 | 145 | 60 | 2.47 |

| du bushing 14080 | straight | 140 | 145 | 80 | 2.47 |

| du bushing 140100 | straight | 140 | 145 | 100 | 2.47 |

| du bushing 15060 | straight | 150 | 155 | 60 | 2.47 |

| du bushing 15080 | straight | 150 | 155 | 80 | 2.47 |

| du bushing 150100 | straight | 150 | 155 | 100 | 2.47 |

| du bushing 16060 | straight | 160 | 165 | 60 | 2.47 |

| du bushing 16080 | straight | 160 | 165 | 80 | 2.47 |

| du bushing 160100 | straight | 160 | 165 | 100 | 2.47 |

| du bushing 160115 | straight | 160 | 165 | 115 | 2.47 |

| du bushing 18080 | straight | 180 | 185 | 80 | 2.47 |

| du bushing 180100 | straight | 180 | 185 | 100 | 2.47 |

| du bushing 19080 | straight | 190 | 195 | 80 | 2.47 |

| du bushing 190100 | straight | 190 | 195 | 100 | 2.47 |

| du bushing 20060 | straight | 200 | 205 | 60 | 2.47 |

| du bushing 20080 | straight | 200 | 205 | 80 | 2.47 |

| du bushing 200100 | straight | 200 | 205 | 100 | 2.47 |

| du bushing 22080 | straight | 220 | 225 | 80 | 2.47 |

| du bushing 220100 | straight | 220 | 225 | 100 | 2.47 |

| du bushing 25080 | straight | 250 | 255 | 80 | 2.47 |

| du bushing 250100 | straight | 250 | 255 | 100 | 2.47 |

| du bushing 26080 | straight | 260 | 265 | 80 | 2.47 |

| du bushing 260100 | straight | 260 | 265 | 100 | 2.47 |

| du bushing 28080 | straight | 280 | 285 | 80 | 2.47 |

| du bushing 280100 | straight | 280 | 285 | 100 | 2.47 |

START YOUR

a project with an Application Engineer