-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

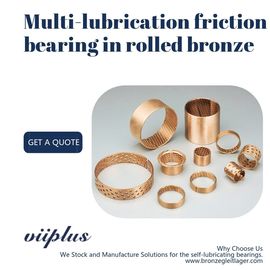

Multi Lubrication Friction Type Bearing In Rolled Bronze Material CuSn8 Bronze For Hydraulics

| Place of Origin | Bushing Manufacturer |

|---|---|

| Brand Name | REPLACEMENT PLAIN BEARINGS |

| Certification | DIN 1494, ISO 3547 |

| Model Number | FB090 BRONZE BUSHINGS |

| Minimum Order Quantity | MATE-TO-ORDER CUSTOM BUSHINGS |

| Price | Negotiable |

| Packaging Details | EXPORT CARTON WOOD PALLET WOODEN CASE |

| Delivery Time | 7-25 work days |

| Payment Terms | T/T, Western Union |

| Supply Ability | STANDARD TOLERANCE BUSHINGS |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Bushings Material | CuSn8 Bronze | Bushing Standard | BK-090, BRM10, COB-090, MBZ-B09, PRM, PRMF, SERIE SBA, SERIE SBB, WB700, WF-WB 700 |

|---|---|---|---|

| Feature | Lubrication Pockets | Bushings Applications | : • Fixing Eyes For Hydraulic Cylinders • Forestry Equipment • Agricultural Equipment • Conveyors And Elevators • Excavators, Etc. |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Self-Lubricating Sintered Bronze Bushing | Characteristic | Bronze Bushings With Grease Reservoirs ( BRO-MET, FB090, BRM10, WB800) |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | wrapped bronze bushings,graphite sleeve bearings |

||

Multi Lubrication Friction Type Bearing In Rolled Bronze Material CuSn8 Bronze For Hydraulics

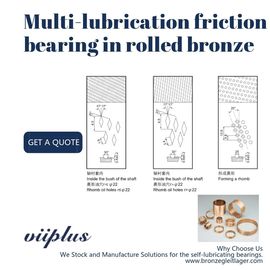

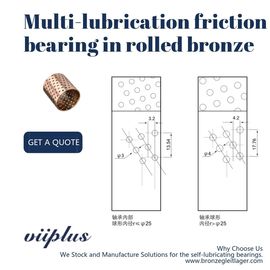

DIN ISO/3547 Multi-Lubrication Friction Bearing In Rolled Bronze Material CuSn8P(Qsn8-0.3) bronze Lubrication pockets For Hydraulics.

competitively priced vs Bronze bushes type BK-090 BK 090-F BK-080,Provides Custom Sliding Bearing & Thrust Washers Solutions.

The bushes CUSN8/CUSN6 are suitable for rotary and oscillatory motions. Initial lubrication with grease is advisable, and a continuous lubricant feed substantially lengthens the service life of the slide bearing.

Available Bushing Type

straight sleeve, thrust gasket, flanged bushing, bearing bush, skateboard, steel sleeve combination.

Description

FB090 bronze rolling bearing, with special formulation of high density copper alloy strip as matrix, can be rolled on the surface of the user's requirements diamond or hemispherical oil holes, oil groove.It has the advantages of high density, large bearing capacity, good wear-resisting performance and long service life.

Bushings Materials

High density bronze roll forming or spherical oil bag, oil hole special synthesis of internal surface to reduce wear and extend the service time and good anti-corrosion function.

DIN ISO/3547 Tolerance

Straight bushings - Dimensions,operating clearance data Shaft F7 and housing tolerances H7 Design of bushing

| diameter | Outer diameter dimension of bushing | Housing | Inner diameter dimensions of bushing | shaft Bushing |

| 10~18 | +0.065 +0.030 |

+0.018 0 |

+0.046 0 |

- 0.016 - 0.043 |

| 18~30 | +0.075 +0.035 |

+0.021 0 |

+0.052 0 |

- 0.020 - 0.020 |

| 30~50 | +0.085 +0.045 |

+0.025 0 |

+0.062 0 |

- 0.025 - 0.064 |

| 50~80 | +0.100 +0.055 |

+0.030 0 |

+0.074 0 |

- 0.030 - 0.076 |

| 80~120 | +0.120 +0.070 |

+0.035 0 |

+0.087 0 |

- 0.036 - 0.090 |

| 120~180 | +0.170 +0.100 |

+0.400 0 |

+0.100 0 |

- 0.043 - 0.106 |

| 180~250 | +0.210 +0.130 |

+0.046 0 |

+0.115 0 |

- 0.050 - 0.122 |

| 250~315 | +0.260 +0.170 |

+0.052 0 |

+0.130 0 |

- 0.056 - 0.137 |

Shaft sleeve advantages

• Maintenance-free operation

• Relubricatable

• It is suitable for dirty environments

• Impact and vibration-resistant

• High permissible load

• Good frictional properties

• No water absorption

• Little play during operation

• Minimal space requirement

VIIPLUS sliding bearings With high precision equipment, a high-level management team and high-quality staff, constantly improve the production process and refine the management platform, strictly in accordance with the global quality certification system to do every detail, to provide high-quality self-lubrication bearing products for the world's industry.

Create perfect bushing quality by heart.

![]()

Cause of bearing damage in short - term use

1. Poor lubrication (about 50%)

According to investigation, poor lubrication is one of the main causes of premature bearing damage.The main reasons include: not filling lubricant or lubricating oil in time;The lubricant or lubricating oil is not filled in place;Improper selection of lubricants or lubricants;Incorrect lubrication, etc.

Suggestion: choose the right lubricant or lubricant and use the right lubrication filling method.

2. Fatigue (about 34%)

Fatigue failure is a common form of bearing damage.Common reasons for fatigue failure may be: bearing long-term overload operation;Not timely maintenance;Improper maintenance;Equipment aging, etc.

Suggestion: select proper bearing type and replace fatigue bearing regularly and timely.

3. Improper installation (about 16%)

(1) during installation, use brute force and directly hit the bearing with a hammer, causing the most damage to the bearing;Is the main cause of deformation.

(2) installation is not in place, installation deviation or not installed to the bearing position, resulting in too small bearing clearance.The inner and outer rings are not in the same center of rotation, resulting in different centers.

Suggestion: select appropriate or professional bearing installation tools, installation should be completed with a special instrument detection.

4. Pollution (about 14%)

Pollution can also lead to premature bearing damage, pollution refers to the dust, metal particles into the bearing interior.The main reasons include: premature opening of bearing packaging before use, resulting in pollution;When installation, the working environment is not clean and causes pollution;The working environment of the bearing is not clean and the working medium is polluted.

Suggestion: it is best not to disassemble the bearing packaging before use;Keep the installation environment clean and clean the bearings to be used;The sealing device of the strengthened bearing.

These are the most common causes of early bearing damage, of course, the cause of early bearing damage is multifaceted, sometimes may be comprehensive reasons.But if the bearing in the use of the above four aspects can be completely correct, the bearing can work normally very often.

Application

SLIDING BEARINGS products has been widely used in all industrial areas

Fixing eyes for hydraulic cylinders

Forestry equipment

Agricultural equipment

Conveyors and elevators

Excavators, etc.