-

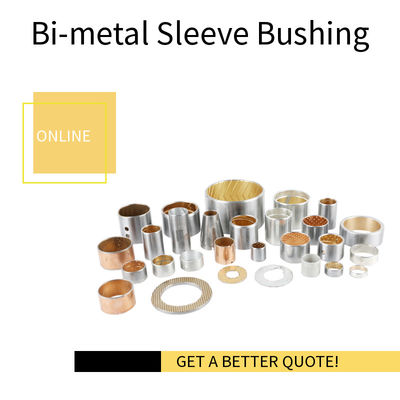

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Bimetal Lead-Free Plain Thin Walled Bearing Imperial & Metric Sizes Bush With Grooves

| Place of Origin | Bimetal Bearing Manufacturers |

|---|---|

| Brand Name | bimetal SAE-797 SAE 48 SAE-799 bushings |

| Certification | Bimetal Bush Material CuPb10Sn10、CuPb6Sn6Zn3 CuPb24Sn4... |

| Model Number | JF800 JF720 JF700 Bimetal Lead-Free Plain Bearings |

| Minimum Order Quantity | 800 Piece/Pieces (Min. Order) |

| Price | $0.20 - $2.00 / Pieces ,Negotiable |

| Packaging Details | export & import bimetal bushings International carton standard |

| Delivery Time | Manufacture Bimetal Bushing In Stock, Delivered Within Days. |

| Payment Terms | TT IN ADVANCE Western Union |

| Supply Ability | casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Meterial | Bimetal ,Bronze/Steel Bushing,is Available With Stainless Steel, Carbon Steel Or Bronze Backing. | Characteristic | Thin Walled Bearing,Low-maintenance And Maintenance-free Plain Bearings |

|---|---|---|---|

| Size | IMPERIAL & METRIC SIZES,Standard Size Available | Type | Cylindrical Bushes Thrust Washers, Strips Or Special Designs |

| Bearing | Bimetal Bronze Steel Bearing | Bushing Sample | Available Imetal Bushing Bearing Manufacturer | Cylindrical Steel Bronze Bushing Series |

| Bimetal Bearings Application | Is Used In Track Rollers, Truck Brakes And Agriculture Machinery, Agricultural, Mechanical Handling And Lifting Applications | Bimetal Bushings | With Non-standard Dimensions, RoHS Customized Bearing Designs |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Steel Backed Bronze Bushing, Bimetallic Bushes | Bimetallic Bearing Bushing | Bimetal Bearing With Steel Backing And Bronze Overlay • Particularly Suitable For High ... Bimetal Plain Bearings To Standard SAE 792 |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | bimetal bush,bimetal bearings,Lead Free Bimetal Bearing Bushes |

||

Bushing Manufacturer & Exporter - Bimetal Bearings Manufacturer & Exporter

The bimetal bushing is backed with high-quality low carbon steel with tin-lead-bronze alloy(CuSn10Pb10) sintered on its surface.

Wear-resistant special additive dispersed sintered bronze bearings with back metals

We believe that by being creative and constantly striving to challenge ourselves we provide the highest-quality bimetal bearing from china.

Bi metal strips Length 1000mm Width 250mm thickness 1.55mm

The bimetal bushing is steel backed with high-quality with tin-

Bimetal Bushing are widely used in various past of automobile industries such as engine, transmission cases, vehicle

Support wheel Bushings, guide wheel bushing, bushing replacement parts

- Con Rod Bearing Bush

- Sleeve Bush for Rocker Arm

- Cam Shaft Bearing Bush

Bimetal Lead-Free Plain Bearings

Bushings Selection

Bimetal bearing bushes have high-performance environmentally friendly dual metal bearings that are customer-specified products. bimetal bearing bushes use low-carbon steel plate as supporting base and powder metallurgy sintering and rolling processes to form a leadless CuSn8Ni steel-copper alloy product. The materials in this product meet RoHS directory/regulation/rule, under certain circumstances can substitute for JF800 products. bimetal bearing bushes have a high load-bearing capacity and good wear-resistance. Its shortcoming is that it cannot be used without oil lubrication. In places where oil lubrication is sufficient, bimetal bearing bushes have superior performance.

Our sales assistant team will provide bronze bushings service for each of your needs.

Quick Response

Once we receive your request, we will contact you, and the sliding bushings qualified type will be recommended to you within 24 hours.

| The designing of oil indentations | ||||||

| In order to fully lubricate the bush when in the performance, the indentations with size as following are recommended. They should be manufactured according to the standard below if without special requirements. | ||||||

| Bush O.D | More than to | 14~22 | 22!44 | 40~50 | 50~100 | 100~180 |

| Lubricating hole | 3 | 3 | 3 | 6 | 7 | |

| The lubricating hole should be away from the butt joint and loading area and designed to be easy-oil-feeding as well. | ||||||

| Normal thickness of the JF bimetal and their tolerances | ||||||||

| Tolerance Thickness | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 | 5 |

| Thickness of steel backing |

0.6 | 1 | 1.4 | 1.9 | 2.3 | 2.8 | 3.2 | 4 |

| Thickness of bronze layer |

0.4 | 0.5 | 0.6 | 0.6 | 0.7 | 0.7 | 0.8 | 1.0 |

| Manufacturable wall thickness |

1+0.25 +0.15 |

1.5+0.25 +0.15 |

2+0.25 +0.15 |

2.5+0.25 +0.15 |

3+0.25 +0.15 |

3.5+0.25 +0.15 |

4+0.25 +0.15 |

4+0.25 +0.15 |

| Manufactured wall thickness |

1-0.025 | 1.5-0.03 | 2-0.035 | 2.5-0.04 | 3-0.045 | 3.5-0.05 | 4-0.055 | 4-0.06 |

| JF JF Bimetal Bushing chemical composition | ||||

| Tolerance Thickness | JF-800 | JF-720 | JF-700 | JF-20 |

| Cu | Remainder | Remainder | Remainder | 0.7~1.3 |

| Pb | 9.0~11.0 | 21.0~27.0 | 26.0~33.0 | - |

| Sn | 9.0~11.0 | 3.0~4.5 | 0.5 | 17.5~22.5 |

| Zn | 0.5 | 0.5 | 0.5 | - |

| P | 0.1 | 0.1 | 0.1 | |

| Fe | 0.7 | 0.7 | 0.7 | 0.7 |

| Ni | 0.5 | 0.5 | 0.5 | 0.1 |

| Sb | 0.2 | 0.2 | 0.2 | - |

| Ai | - | - | - | |

| Si | - | - | - | 0.7 |

| Mn | - | - | - | 0.7 |

| Ti | - | - | - | 0.2 |

| Other | 0.5 | 0.5 | 0.5 | 0.5 |

| JFBimetel Bushing Physical properties | |||||

| Physical properties | JF-800 | JF-720 | JF-700 | JF-20 | |

| Max. static load pressure N/mm2 |

150 | 130 | 120 | 100 | |

| Tensile strength N/mm2 |

150 | 150 | 200 | 200 | |

| Max. speed(oil) m/s | 5 | 10 | 15 | 25 | |

| Friction coef(Oill) | 0.06~0.14 | 0.06~0.16 | 0.08~0.16 | 0.08~0.17 | |

| PV limit N/mm2 m/s |

Grease | 2.8 | 2.8 | 2.5 | - |

| Oil | 10 | 10 | 8 | 6 | |

| “Sapphire Fatigue Calss Mpa | 125 | 115 | 105 | 85 | |

![]()

Type:-Flanged

-Solid Bronze

-Welded Joint

-Split Joint

-Clench Lock

-Sintered / Powder Metal

-Graphite Impregnated

Application

The bimetal bushing will most notably benefit transmissions and truck brakes as well as agricultural, mechanical handling and lifting applications. They boast a high load capacity and very good resistance to fatigue strength at high temperatures.

Bimetal bearings are able to handle heavy loads and shock-loading conditions. Our bimetal bearings have anti-corrosion capabilities and are easy to install, making them ideal for emergency replacements.VIIPLUS is available with stainless steel, carbon steel, or bronze backing.

Bushings are made of Steel backed lead bronze lined bushings and have the following layers:

-

Sinter bronze powder: good wear resistance and excellent load-carrying capacity.

-

Steel backing gives exceptionally high load carrying capacity, excellent heat dissipation.

-

Copper plating 0.002mm, good corrosion resistance.

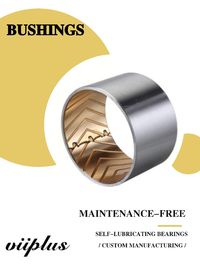

Bimetal bearings thin-walled bushings are available with stainless steel, carbon steel, or bronze backing. Bimetal Bushings are able to handle heavy loads and shock-loading conditions. Our bimetal bearings have anti-corrosion capabilities and are easy to install, making them ideal for emergency replacements.

This is a bimetal bearing material in which aluminum alloy and copper alloy comprise a two- or three-layer structure with a steel backing. This structure, whose mechanical strength is high, can be used under lubricated conditions and high-speed/high-load operation.

It can be made from a variety of different materials, depending on the application, use conditions, and lubrication.

Load capability can be improved by oil holes, grooves, etc., depending on lubrication conditions. In some cases, a dry bearing can also be used under lubricated conditions.

Carrier Roller Bushings

Viiplus offers a broad range of sizes, forms, and materials in monometallic and bimetallic bearings. Bimetal and metal bearings offer excellent corrosion resistance in industrial outdoor applications and in water, marine, and offshore environments.

What is Bimetal Bearings & Bushings?

Bimetallic bearing is one of the bearing lubrication systems, the product is high-quality low carbon steel back as substrate, the bronze alloy on the surface, through several high-temperature sintering and density and rolled copper and steel bimetallic strip coiling, suitable for medium and high impact load under bush and thrust washer and so on many kinds of USES.

Bimetal Bearing Bushings are composed of two metal strips, in two different materials; The first is normally in steel/bronze / stainless steel backed with low friction and excellent wear resistance.

-

JF800 Oilless Bimetal Sliding Self Lubricating Bearing Bushing

-

JF800 Steel + Lead Bronze Powder Conventional lubricating

Characteristic

Oilless Bimetal Bronze Steel Bearing Bushes, Split Bush Bearing VSB-80 Standard Size Custom composite CuPb10Sn10 bimetal bush high-quality oilless JF800 Bimetal Metal Bushing

-

Wrapped composite sliding bearing

-

Copper-plated or tin-plated steel/bronze

-

Low-maintenance

-

With lubrication pockets

Steel backing gives exceptionally high load carrying capacity, excellent heat dissipation. Sintered bronze powder gives good wear resistance and excellent load-carrying capacity. Copper plating has good corrosion resistance.

Bimetal bearing with steel backing and bronze overlay

Lead-free bearing composition with indents as reservoir for the grease, also available without indents

High load capacity, very good resistance to fatigue strength at high temperatures

Suited to harsh operating conditions

Particularly suitable for high specific loads with oscillating motion and low frequency

Fine turned shafts suitable

![]()

Typical Application

This material is recommended to be used under the medium speed and medium load condition with oil or grease lubricating. It is widely used for motor rod ends, Kingpin bushing, undercarriage rollers, hydraulic cylinder rod eyes of construction machines, and spherical joint bearings of agricultural machines. Because this material is with lead, the specific parts are not allowed to be used according to certain laws or regulations. Widely used in the automotive, common industrial-like steering gear, power steering, pedal bushes, king-pin bushes, tailgate pivots, mechanical handling, lifting equipment, hydraulic motors, agricultural machines, etc.

-

Forklifts bushing

-

Pallet Trucks bushing

-

Cranes bronze bushes

-

Excavators bearing bronze

Technical Data

|

Dynamic load limit |

60N/mm² |

|

Static Load |

120N/mm² |

|

frictional coefficient |

0.08~0.2 |

|

PV limit |

2.8N/mm²*m/s |

|

Max Speed |

>2m/s |

|

Temp.limit |

-40°C~+250°C |

![]()

Properties

-

For high load capacity and oscillating movement, as well as for rough operation and temperature load. Long-run lubrication because of lubricant storage.

Materials

-

Support material Steel copper-plated / tin-plated

-

Sliding layerCuPb10Sn10

Tolerance Details

-

Housing ØH7

-

Bushing inner-Ø after mountingH9

-

Shaft tolerancef7 to h8

Maintenance

-

is a low-maintenance composite sliding bearing, but primary lubrication is necessary. Oil or grease lubrication is possible. Due to solid lubricant storages, lubrication clearances are reduced to a minimum!

![]()

Bimetal Bushings Size

|

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Caption

Special dimensions are available on request

Get in touch ...

You can use our “Enquiry Form” to get in touch with us. One of our sales team will contact you immediately.