-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

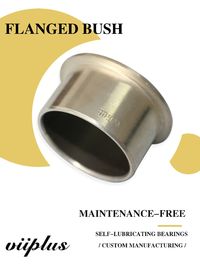

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

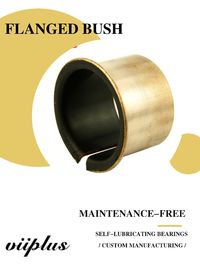

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Custom Metal Backed Bearing Split Bushings Copper Plating, Flanged, High Quality

| Place of Origin | Self Lubricating Bearings Manufacturers |

|---|---|

| Brand Name | VIIPLUS |

| Certification | DIN 1494, ISO 3547 |

| Model Number | Flange bushing |

| Minimum Order Quantity | negotiable |

| Price | Competitively Priced vs DU DX, Provides Lubricating Bush |

| Packaging Details | EXPORT CARTONS |

| Delivery Time | 7-20 work days |

| Payment Terms | Western Union, T/T |

| Supply Ability | Flanged Bronze Bushings, Bronze Thrust Washers, Self Lubricating Bronze Bushings |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Low Price Custom Metal Sleeve Flange Bearing Du Sf1 Bush Bushing | Material | Steel,bronze,ptfe |

|---|---|---|---|

| Size | Customized | Quality | Free Maintenance |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | PTFE Coated Self Lubricating Plain Bearing, Teflon Self Lubricating Plain Bearing, Steel Backed Self Lubricating Plain Bearing | Characteristic | Втулки скольжения (биметаллические подшипники скольжения) |

| Dry Slide Bearing | Self Lubricating Plain Bearing Work In High Temp & Submerged Applications Where Grease, Oil & Plastics Fail. Reduced Costs & Downtime. Non-galling. Increased Reliability. Run Dry & Keeps Running. | Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ |

| High Light | self lubricating bearing,sintered self lubricating bushes |

||

Self Lubricating Plain Bearing

Oilless Flange Sleeve Bearing Bushing wholesaler and supplier,Advantages of oilless sliding materials.Achieving oil-free lubrication, Solving friction problems, Reducing maintenance and longer component life, Eliminating oil contamination, Achieving total cost reduction.

Compound PTFE Flange Bushing Composite plain bearings, oil-free sliding sleeve, find complete information about composite sliding bearings, oil-free sliding sleeve, Dx bearing, oil-free sliding bearing, POM bearing from Chinese sliding bearings supplier or manufacturer

Advantage of the bushing

The self-lubricating metal bushing used a high quality low-carbon steel plate as a base, sintered porous bronze as an intermediate layer and the -lead compound as a surface. It offers the property of a good self-lubrication, low wear, low friction, good sliding characteristics, low noise.

It has been widely applied to various mechanical sliding positions, such as textile machines, printing machines, hydraulic pressure transit vehicles, tobacco machines, gymnastic tools and agricultural machines, etc.

Application

Overseas companies have successively discovered the benefits of oil-free bushings. They are used in large projects. For different areas: from resources to energy.

|

Product Name |

Flange Bushing |

|

Max Load Capacity |

Static load 250N/mm2 ; Dynamic load 140N/mm2 |

|

Max Load Speed |

Dry friction 2.5m/s ; Oil lubrication 5.0m/s |

|

Max PV Value Limit |

Dry friction 3.6N/mm2 m/s ; Oil lubrication 50N/mm2 m/s |

|

Friction Coefficient |

Dry friction 0.08~0.20 ; Oil lubrication 0.02~0.07 |

|

Work Temperature |

-195℃~+280℃ |

|

Thermal Conductivity |

42w/m k |

|

Production Process |

Material cutting~Bronze sintering~PTFE sintering~Sizing~Coiling~Surface finish~Packing |

|

Application Feature |

Self lubrication, Low wear, Low friction, Low noise, Good sliding characteristic, Pb free |

Product Description

|

Product Name

|

Bearing PTFE Coated Bronze Steel Bearing Bush Oilless Slide Plain Bushing

|

|

Material

|

Steel+Bronze+PTFE+Pb+Filler

|

|

Size

|

We can develop according to customers' special requirement.

|

|

Standard

|

ISO/TS16949, SGS, CNAS

|

|

Working Temperature

|

-200~+280℃

|

|

Outside Surface

|

Copper/Tin

|

|

Used

|

printing, woven, tobacco and gymnastic machinery, pneumatic cylinder.

|

Features

- self-lubricating bushings offer very good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions

- Bushing material suitable for lubricated applications

- Anti-friction bearing suitable for linear, oscillating and rotating movements

![]()

Inner Packing: 100 Pieces per Anti-rust plastic film, Vacuum Plastic Bags.

Outer Packing: 1000-2000 Pieces per Hard Carton, Wooden Case, Wooden Pallet.

Shipping Packing: 20 Carton per Wooden Case or Pallet

Shipping Term: By Express, By Air, By Land, By Sea.

Delivery Term: FOB, CFR, CIF, EXW

du bushing size chart

| Di (mm) | Do (mm) | Sfl (mm) | Dfl (mm) | B (mm) | bearing | shaft | The largest diameter(mm) | Minimum diameter (mm) | The maximum clearance(mm) | The minimum clearance(mm) | |

| BB0304DU | 3 | 4.5 | 0.75 | 7 | 4 | H6 | h6 | 3.048 | 3 | 0.054 | 0 |

| BB0404DU | 4 | 5.5 | 0.75 | 9 | 4 | H6 | h6 | 4.048 | 4 | 0.056 | 0 |

| BB0505DU | 5 | 7 | 0.925 | 10 | 5 | H7 | f7 | 5.055 | 4.99 | 0.077 | 0 |

| BB0604DU | 6 | 8 | 0.925 | 12 | 4 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| BB0608DU | 6 | 8 | 0.925 | 12 | 8 | H7 | f7 | 6.055 | 5.99 | 0.077 | 0 |

| BB0806DU | 8 | 10 | 0.925 | 15 | 5.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB0808DU | 8 | 10 | 0.925 | 15 | 7.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB0810DU | 8 | 10 | 0.925 | 15 | 9.5 | H7 | f7 | 8.055 | 7.99 | 0.083 | 0.003 |

| BB1007DU | 10 | 12 | 0.925 | 18 | 7 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1009DU | 10 | 12 | 0.925 | 18 | 9 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1012DU | 10 | 12 | 0.925 | 18 | 12 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1017DU | 10 | 12 | 0.925 | 18 | 17 | H7 | f7 | 10.058 | 9.99 | 0.086 | 0.003 |

| BB1207DU | 12 | 14 | 0.925 | 20 | 7 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1209DU | 12 | 14 | 0.925 | 20 | 9 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1212DU | 12 | 14 | 0.925 | 20 | 12 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1217DU | 12 | 14 | 0.925 | 20 | 17 | H7 | f7 | 12.058 | 11.99 | 0.092 | 0.006 |

| BB1412DU | 14 | 16 | 0.925 | 22 | 12 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| BB1417DU | 14 | 16 | 0.925 | 22 | 17 | H7 | f7 | 14.058 | 13.99 | 0.092 | 0.006 |

| BB1509DU | 15 | 17 | 0.925 | 23 | 9 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1512DU | 15 | 17 | 0.925 | 23 | 12 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1517DU | 15 | 17 | 0.925 | 23 | 17 | H7 | f7 | 15.058 | 14.99 | 0.092 | 0.006 |

| BB1612DU | 16 | 18 | 0.925 | 24 | 12 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| BB1617DU | 16 | 18 | 0.925 | 24 | 17 | H7 | f7 | 16.058 | 15.99 | 0.092 | 0.006 |

| BB1812DU | 18 | 20 | 0.925 | 26 | 12 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB1817DU | 18 | 20 | 0.925 | 26 | 17 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB1822DU | 18 | 20 | 0.925 | 26 | 22 | H7 | f7 | 18.061 | 17.99 | 0.095 | 0.006 |

| BB2012DU | 20 | 23 | 1.45 | 30 | 11.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2017DU | 20 | 23 | 1.45 | 30 | 16.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2022DU | 20 | 23 | 1.45 | 30 | 21.5 | H7 | f7 | 20.071 | 19.99 | 0.112 | 0.01 |

| BB2512DU | 25 | 28 | 1.45 | 35 | 11.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB2517DU | 25 | 28 | 1.45 | 35 | 16.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB2522DU | 25 | 28 | 1.45 | 35 | 21.5 | H7 | f7 | 25.071 | 24.99 | 0.112 | 0.01 |

| BB3016DU | 30 | 34 | 1.95 | 42 | 16 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| BB3026DU | 30 | 34 | 1.95 | 42 | 26 | H7 | f7 | 30.085 | 29.99 | 0.126 | 0.01 |

| BB3516DU | 35 | 39 | 1.95 | 47 | 16 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| BB3526DU | 35 | 39 | 1.95 | 47 | 26 | H7 | f7 | 35.085 | 34.99 | 0.135 | 0.015 |

| BB4016DU | 40 | 44 | 1.95 | 53 | 16 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| BB4026DU | 40 | 44 | 1.95 | 53 | 26 | H7 | f7 | 40.085 | 39.99 | 0.135 | 0.015 |

| BB4516DU | 45 | 50 | 2.45 | 58 | 16 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |

| BB4526DU | 45 | 50 | 2.45 | 58 | 26 | H7 | f7 | 45.105 | 44.99 | 0.155 | 0.015 |