-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Garlock POM Composite Polymer Plain Bearings Wear Resistance

| Place of Origin | china |

|---|---|

| Brand Name | viiplus.com |

| Certification | Plain Sleeve Bearings Standards met: RoHS |

| Model Number | POM Lead Free |

| Minimum Order Quantity | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price | Contact us |

| Packaging Details | Standard package, Pallet or container, As per customized specifications |

| Delivery Time | Shipped in 3-20 work days |

| Payment Terms | TT IN ADVANCE,L/C,Western Union |

| Supply Ability | bronze sleeve bushings, China, manufacturers, suppliers, factory, wholesale, Metallic Self Lubricating Bushings, Cast Iron Bearing, Sleeve Bushing, POM Bearing, Cast Iron Plain Bearing, Lubrication Bronze Bushing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Meterial | Steel +copper + Pom | Plating | Tin Or Copper |

|---|---|---|---|

| Types | POM Composite Gleitlager Anlaufscheiben | Application | Impact Load And Dusty Environment |

| Parts | Bushings Thrust Washers Strips | Categories | Plain Bearings |

| Get A Better Quote | Tiffany@viiplus.com | Get A Better Quote | Tiffany@viiplus.com |

| Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ | High Light | Slit Oilless Bronze Bushing, Anti Fatigue Oilless Bronze Bushing, Maintenance Free Oilless Bronze Bushing |

| Gleitalger | A Plain Bearing, Or More Commonly Sliding Contact Bearing And Slide Bearing, Is The Simplest Type Of Bearing, Comprising Just A Bearing Surface And No Rolling Elements. Therefore, The Journal Slides Over The Bearing Surface. The Simplest Example Of A Plain | Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ |

| High Light | Wear Resistance Polymer Plain Bearings,POM Composite Polymer Plain Bearings |

||

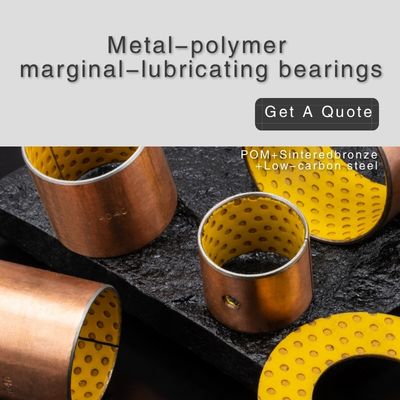

Garlock Metal-Polymer Marginal-Lubricating Bearings

High-Quality Metal-polymer marginal-lubricating bearings To Your Specifications- China Supplier

Bearings Bushing For Electric Motors. Got it.

Trusted Sleeve Bushing Supplier in China

Fulfill your bushing research needs - Available at bronzegleitlager.com

COMPOSITION

- Metal-Polymer Composite Bushing Material

- Steel Back + Porous Bronze Sinter +

POM with Lubrication Indents

Garlock Bearings, Bushing No Flange Split (GGB equivalent)

Material

Steel Backed Composite

032DXR032

Die & Mold Plain-Bearing - 2.0000 in Bore, 2.1883 in OD, 2.0000 in Length, POM Material

Potential applications for self-lubricating bearings include:

- Wind energy

- Car washing machines

- Cleaning machines

- Drum systems

- Bevelling equipment

- Handling systems

- Conveyor belts (pulleys)

- Printing machines

- Heating and ventilation equipment

- Hoists

- Cranes

- Textile machinery

- Special machines

- Bakery equipment

- Marine equipment.

Crane Bushing Specifications

![]()

5-CYLINDER POM BUSHING ASSEMBLY

![]()

3- POM bushing Metal-polymer marginal-lubricating bearings

China Metal-polymer marginal-lubricating bearings supplier - Select 2021 high quality Metal-polymer marginal-lubricating bearings products in best price from certified Chinese Bearing supplier.

Operating Performance

Dry

Poor

Grease Lubricated

Very Good

Oil Lubricated

Good

Fresh Water

Poor

Salt Water

Poor

The Advantages Of Metal-polymer marginal-lubricating bearings

It is suitable for boundary lubricating applications. It is recommended to lubricate the components with grease before assembling. The oil deposit can hold the lubricant with optimized matrix. Lubricating during the operation helps to prolong the bearing duration. The low friction coefficients, good wear resistance and reliable loading capacity of the bearing ensure a suitable application under low speed rotating and oscillating motion. CSB-20M is a material with POM thickness of 0.2-0.35mm without oil deposits on the surface, it is a machinable material after assembling.

Structure:

1.POM thickness 0.30~0.50mm, provides good wear resistance. This bearing surface carries a pattern of circular indents which should be filled with grease on assembly of the bearing.

2.Sintered bronze thickness 0.20-0.35mm, provides strong mechanical bond and excellent thermal conductivity.

3.Low-carbon steel, provides mechanical strength and thermal conductivity

![]()

Typical Applications

The material has good wear resistance and it is suitable for middle to high load applications under the work conditions

of impact load and dusty environment. A pre-lubricating is necessary before assembling. The applications of this material include the commercial vehicle axel, brake system, suspension system, agricultural machinery, forest machinery and material handling machinery. It could be used to replace some traditional steel or bronze sleeves.

Availability

Bearing forms available in standard dimensions

Cylindrical bushes

Thrust washers

Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs

![]()

Characteristics

Metal-polymer marginal-lubricating bearings for grease or oil lubricated applications

Standard parts contain grease indents in the sliding layer; plain sliding layer available by request

Optimum performance under relatively high loads and low speeds

Suitable for linear, oscillating and rotating movements

Wide range of parts available from stock

Technical Data - Metric Bearing Properties

| GENERAL | Unit | Value | |

| Maximum load, p |

Static |

N/mm2 |

140 |

| Operating temperature |

Min |

°C |

– 40 |

| Coefficient of linear thermal expansion | Parallel to the surface | 10-6/K | 11 |

| Normal to the surface | 10-6/K | 29 |

| GREASE LUBRICATED | |||

| Maximum sliding speed, U | m/s | 2.5 | |

| Maximum pU factor | N/mm2 x m/s | 2.8 | |

| Coefficient of friction | 0.06 – 0.12 |

| RECOMMENDATIONS | |||

| Shaft surface roughness, Ra | µm | ≤ 0.4 | |

| Shaft surface hardness |

Normal |

HB |

> 200 |

Technical Data - Imperial Bearing Properties

| GENERAL | Unit | Value | |

| Maximum load, p |

Static |

psi |

20 000 |

| Operating temperature |

Min |

°F |

– 40 |

| Coefficient of linear thermal expansion | Parallel to the surface | 10-6/F | 6 |

| Normal to the surface | 10-6/F | 17 |

| GREASE LUBRICATED | |||

| Maximum sliding speed, U | fpm | 500 | |

| Maximum pU factor | psi x fpm | 80 000 | |

| Coefficient of friction | 0.06 – 0.12 |

| RECOMMENDATIONS | |||

| Shaft surface roughness, Ra | µin | ≤ 16 | |

| Shaft surface hardness |

Normal |

HB |

> 200 |