-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

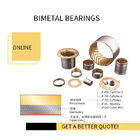

Steel CuPb10Sn10 Bimetal Bearing Bushes For Auto Engine Con Rod

| Place of Origin | China |

|---|---|

| Brand Name | VIIPLUS |

| Certification | ISO9001 |

| Model Number | Self-lubricating bearing |

| Minimum Order Quantity | Negotiable |

| Price | Negotiable |

| Packaging Details | Export Carton Wood Pallet Wooden Case |

| Delivery Time | 7-25 work days |

| Supply Ability | casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Cylinder Bushing | Material | Steel+CuPb10Sn10 |

|---|---|---|---|

| Origin | China | Sample | Available |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Steel Backed Bronze Bushing, Bimetallic Bushes | Bimetallic Bearing Bushing | Bimetal Bearing With Steel Backing And Bronze Overlay • Particularly Suitable For High ... Bimetal Plain Bearings To Standard SAE 792 |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | Steel CuPb10Sn10 Bimetal Bearing Bushes,self lubricating Bimetal Bearing Bushes,ISO9001 cylinder bushing |

||

China Bimetallic Oilless Plate - self-lubricating bearing Sale

For bitzer semi-hermetic compressor crankshaft bushingBIMETAL BEARINGS CUPB30 CATALOG.pdf

China self-lubricating bimetal bearing, Similar To DEVA Metal. Maintenance Free Slide Plates Within Tire Mold Container, Factory Price, Contact Us! View News. Read News. Custom Auto Engine Parts Con Rod CuPb10Sn10 Bering Bushing

Bimetallic bearings to the high-quality low-carbon steel substrate, the surface of the sintered copper alloy having a low friction characteristic (CuPb10Sn10, CuPb6Sn6Zn3, CuPb24Sn4, CuPb30, AlSn20Cu, CuSn8Ni) as a wear layer bearing copper alloy surfaces can be processed in accordance with the use of a variety of conditions need type tank, oil hole, oil hole, so as to fit in unsustainable fuel refueling or difficult situations. Secondary extrusion material through the secondary sintering can be a good bonding strength and optimum carrying capacity.

|

Material |

Steel + CuPb10Sn10 |

|

Typical Application |

con-rod of automobile engines, engineering, and agriculture machinery, heavy-duty construction machinery, etc. |

|

Max Dynamic Load |

140N/mm² |

|

Max Line Speed (Grease) |

2.5m/s |

|

Max PV Value Limit (Grease) |

2.8N/mm².m/s |

|

Friction Coefficient (Grease) |

0.05~0.15 |

|

Max Line Speed (Oil) |

5m/s |

|

Max PV Value (Oil) |

10N/mm².m/s |

|

Friction Coefficient (Oil) |

0.04~0.12 |

|

Max Working Temperature |

Grease 150ºC, Oil 250ºC |

|

Mating Axis |

Hardness ≥53HB, Roughness Ra=0.32~0.63 |

|

Alloy Layer Hardness |

60-90HB |

|

Thermal Conductivity |

47W/MK |

|

Coefficient Of Linear Expansion |

18×10-6/K |

|

We can also develop according to customers special request while out of this table |

|

Tolerances Of Machined And Non - machined Thickness

| Nominal Thickness | Tolerances+ of Series B (non-machinable) | Tolerances of Series C (non-machinable) |

| 1.0 | -0.025 | +0.25 +0.15 |

| 1.5 | -0.030 | +0.25 +0.15 |

| 2.0 | -0.035 | +0.25 +0.15 |

| 2.5 | -0.040 | +0.30 +0.15 |

| 3.0 | -0.045 | +0.30 +0.15 |

| 3.5 | -0.050 | +0.30 +0.15 |

Oil Hole Form

![]()

Buckle Form

Characteristics

Bimetal-bearing is a bimetal bearing, wrapped of steel sheets with a layer of lead bronze.

The standard sizes are fitted with lubrication indents on the running surface. For standard bearings is normally the steel backing copper plated to improve the corrosion resistance. The layer of lead bronze makes it possible to use these bearings with relatively long lubrication intervals.

Bimetal-bearings can be manufactured with a thicker lead bronze layer for applications where the bearing has to be machined after mounting. The material of the layer can be fitted to the special needs of the application in question.

Structure And Composition

Steel Backing and Leaded Bronze Overlay

Steel + CuPb10Sn10 with indents

Technical data

| Material: | Copper plated steel backing, lead bronze layer (CuPb10Sn10) |

| Yield point: | (Rp0,2) ca 240 N/mm2 |

| Tensile strength: | (Rm) ca 350 N/mm2 |

| Hardness: | ca 90 – 110 HB |

| Friction: | Depends on the material and the performance of the layer. |

| Max speed: | 3,0 m/s |

| Temperature range: | -100 / +260 °C |

| Load | Speed |

| Ca: 240 N/mm2 | 0 m/s |

| 120 N/mm2 | 0,01 m/s |

| 40 N/mm2 | 2,0 m/s |

Benefits:

Rather a high load capacity.

Possibility to machine the inside diameter after mounting.

High-level thermal conductivity.

Good chemical resistance.

Wide range of temperature.

Operating Performance

| Dry | Poor |

| Oil-lubricated | Good |

| Grease lubricated | Very Good |

| Water lubricated | Poor |

| Process fluid lubricated | Poor |