-

Oilless Bushes

-

Wrapped Bronze Bearings

-

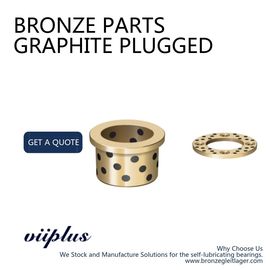

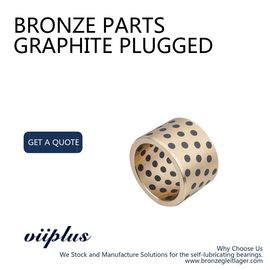

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Phosphor Bronze Graphite Plugged Bushings Cast Bronze Bearings Material

| Place of Origin | Graphite Bearings Manufacturers |

|---|---|

| Brand Name | VIIPLUS |

| Certification | DIN GB-CuSn5Zn5Pb5 |

| Model Number | Solid bushing, Phosphor Bronze Bearings |

| Minimum Order Quantity | NEGOTIABLE |

| Price | Price Graphite Bushing Parts Factory Price |

| Packaging Details | BUSHING EXPORT CARTONS,WOODEN CASE, SPECIFY REQUIREMENTS |

| Delivery Time | FAST DELIVERY |

| Payment Terms | TT IN ADVANCE, Western Union |

| Supply Ability | Bronze Bushings Online • Sliding Bearings Manufacturers • Self-lubricating Bushing Suppliers |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Marerial | Phosphor Bronze Graphite Bushing | Size | ID*OD*H |

|---|---|---|---|

| Standard Material | DIN GB-CuSn5Zn5Pb5 | Type | Plugged |

| Application | Rubber Machine, Light Industry And Machine Tools Industry Etc. | Similar | #500-serie, BWG, BWG-F, COB-05, COB-050 T.o.m. -055, COB-056 T.o.m. -057, CSB 650-serie, JDB-serie |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| Item | Bronze Grafitado | Graphite Plugged Bushings | Purchase Oilless Bush #500 Spherical Bearing (SPS) From China, Factory Automation & Metal Molding Parts, Industrial Tools And Consumables. |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | graphite impregnated bushings,graphite filled bronze bushes |

||

Phosphor bronze, a unique alloy composed primarily of copper with the addition of phosphorus and other elements, is renowned for its excellent mechanical properties, corrosion resistance, and wear resistance. When combined with graphite, phosphor bronze creates a material that offers superior lubrication and reduced friction, making it ideal for use in bushings and bearings.

Graphite plugged bushings, specifically made from phosphor bronze, provide a robust and long-lasting solution for various industrial applications. The graphite plugs act as solid lubricants, ensuring smooth and efficient operation even in high-temperature or high-pressure environments. This combination of phosphor bronze and graphite offers exceptional wear resistance and durability, extending the lifespan of the bushings significantly.

Cast bronze bearings made from phosphor bronze material exhibit similar characteristics, providing reliable performance and reduced maintenance requirements. The material's corrosion resistance ensures that the bearings can withstand harsh environments and maintain their integrity over time.

In summary, phosphor bronze graphite plugged bushings and cast bronze bearings are excellent choices for industrial applications where durability, wear resistance, and smooth operation are critical. The unique properties of phosphor bronze, combined with the lubrication provided by graphite, make these components ideal for a wide range of mechanical systems and devices.

Phosphor Bronze Graphite Plugged Bushings Cast Bronze Bearings Material, 65x55x40 graffito bearing bushing buje de bronce grafito

Plug graphite bearings are primarily used in applications that need continual lubrication in hard to reach areas. Graphite is mechanically forced into the holes/grooves under extreme pressure. A film of lubricant is transferred to the shaft as it begins to turn. These bearings offer continuous lubrication over long periods without maintenance.

![]()

Introduction

1.The solid bronze/iron material is ideally suited for highly demanding applications in tough environments. We offer a standard assortment of plain sleeve bushings, flanged bushings and sliding plates in accordance with ISO 4379 and DIN1850.

2.The solid bronze body can be drilled holes and filled solid graphite lubricant, in this way it can be used in oilless environments.

3.Also the solid bronze body can be machined oil grooves and holes, it can get better lubricating after filled with grease.

Features and advantages

1.Insensitive to dirty environment

2.Resistant to shock loads and vibrations at slow speeds

3.Enable operation with a poor shaft surface finish

4.Good resistance to corrosive conditions

![]()

Material

Phosphor bronze, also known as phosphorus bronze or tin phosphorus bronze, is an alloy material composed primarily of copper, tin, and phosphorus. It is a type of copper alloy that exhibits excellent mechanical properties and electrical conductivity.

The composition of phosphor bronze typically includes the following elements:

1.Copper (Cu): The main component of phosphor bronze, accounting for the majority of its weight. Copper contributes to the alloy's electrical conductivity, ductility, and corrosion resistance.

2.Tin (Sn): Added to the alloy in a range of 2% to 8% by weight. Tin improves the strength and hardness of the material, as well as its corrosion resistance.

3.Phosphorus (P): Present in a small amount, typically ranging from 0.03% to 0.35% by weight. Phosphorus acts as a deoxidizer and can improve the mechanical properties of the alloy, such as its toughness, elasticity, wear resistance, and corrosion resistance.

In addition to these primary elements, phosphor bronze may also contain trace amounts of other elements like iron (Fe) and zinc (Zn), which can further enhance its properties. The exact composition of phosphor bronze can vary depending on the specific alloy grade and manufacturer.

Due to its excellent combination of mechanical properties, electrical conductivity, and corrosion resistance, phosphor bronze is widely used in various industrial applications. It is commonly employed in the manufacture of mechanical parts, electrical components, and heat exchangers.

Solid Bronze bushings and plates are made completely of tin bronze, CuSn10P, which has very good machine ability. All surfaces of the solid bronze bushings are machined.

Solid iron bushings and plates are made in same way of bronze material, but it is much lower costs if you are not in high performance requirements.

Examples of applications

1.Construction machinery

2.Transport equipment

3.Pulp and papermaking machinery

4.Off-shore equipment

- Cylindrical product: bushings, bearings, bronze bearings

- Flat product: slide plates, guide bushing

- Continuous casting centrifugal casting,Bronze Plugged Graphite Bearings Cast Bronze Bearings Material made to order online.It is based on high strength copper alloy of special techniques. The solid lubricant is inlayed by certain angle, density and special formula, and then is processed exactly. The product is widely applied to casting machine, mining machinery, shipping, steam turbine, Injection machinery and automobile mounding, etc.

| Material Compostion and Properties | |||||||

| Code | BRONZE PARTS | BRONZE PARTS | BRONZE PARTS | BRONZE PARTS | BRONZE PARTS | BRONZE PARTS | BRONZE PARTS |

| (500#) | (500#S1) | (500#S2) | (500#S3) | (500#S4) | (HT250) | (Gcr15) | |

| Code | CuZn25Al | CuZn25Al | CuAl9Fe4 | CuSn5P | CuSn12 | HT250 | Gcr15 |

| 5Mn3Fe3 | 5Mn3Fe3 | Ni4Mn2 | b5Zn5 | ||||

| Density | 8 | 8 | 8.5 | 8.9 | 9.05 | 7.3 | 7.8 |

| Hardness HB | >210 | >250 | >150 | >70 | >80 | >190 | HRC>58 |

| N/mm2 Tensile strength | >750 | >800 | >800 | >200 | >260 | >250 | >1500 |

| Elongation% | >12 | >8 | >15 | >10 | >8 | >5 | >15 |

| Coefficien of linear expansion 10-5/℃ | 1.9 | 1.9 | 1.9 | 1.8 | 1.8 | 1 | 1.1 |

| Limit Temp ℃ | -40~+300 | -40~+150 | -40~+400 | -40~+400 | -40~+400 | -40~+400 | -40~+400 |

| Max.load N/mm2 | 100 | 120 | 150 | 60 | 70 | 80 | 200 |

| m/min Max.speed (Dry) | 15 | 15 | 20 | 10 | 10 | 8 | 5 |

| Max.PVN/mm2 *m/min | 200 | 200 | 60 | 60 | 80 | 40 | 150 |

| 300N/mm2 | <0.01 | <0.005 | <0.04 | <0.05 | <0.05 | <0.015 | <0.002 |

| Base Material International | |||||||

| Material Codes | China Brands GB1176-87 | Intenational ISO 1338 | Germany DIN | Japan JIS | America ASTM(UNS) | England BS | France NF |

| BRONZE PARTS(500#) | ZCuZn25Al6 Fe3Mn3 | GCuZn25Al6 Fe3Mn3 | DIN1709 G-CuZn25Al5 | H5102 CAC304 | B30-92 C86300 | HTB2 | |

| BRONZE PARTS(500#S1) | ZCuZn25Al6 Fe3Mn3 | GCuZn25Al6 Fe3Mn3 | DIN1709 G-CuZn25Al5 | H5102 CAC304 | B30-92 C86300 | HTB2 | |

| BRONZE PARTS(500#S2) | ZCuSn5 Pb5Zn5 | GCuPb5 Sn5Zn5 | DIN1705 G-CuSn5ZnPb | H5111 BC6 | B30-92 C83600 | LG2 | CuPb5 Sn5Zn5 |

| BRONZE PARTS(500#S3) | ZCuAl9Fe4 Ni4Mn2 | GCuAl10 FeNi5 | DIN17656 G-CuAl10Ni | H5114 AlBC3 | B30-92 C95500 | AB2 | CuAl10 Fe5Ni5 |

| BRONZE PARTS(HT250) | GB5675-85 HT250 | FC250 | ASTM Class40 | ||||

| Solid Lubricant | |||||||

| Lubricant | Features | Typical application | |||||

| Graphite+add | Excellent resistance against chemical attacks and low friction, Temp limit 400℃ | Suit for general machines and under atmosphere | |||||

| Type | Spec | Type | Spec | ||

| BRONZE GRAPHITE BUSHING | 808 | 8×12×8 | BRONZE GRAPHITE BUSHING | 1640 | 16×22×40 |

| BRONZE GRAPHITE BUSHING | 810 | 8×12×10 | BRONZE GRAPHITE BUSHING | 1812 | 18×24×12 |

| BRONZE GRAPHITE BUSHING | 812 | 8×12×12 | BRONZE GRAPHITE BUSHING | 1815 | 18×24×15 |

| BRONZE GRAPHITE BUSHING | 815 | 8×12×15 | BRONZE GRAPHITE BUSHING | 1820 | 18×24×20 |

| BRONZE GRAPHITE BUSHING | 1008 | 10×14×8 | BRONZE GRAPHITE BUSHING | 1825 | 18×24×25 |

| BRONZE GRAPHITE BUSHING | 1010 | 10×14×10 | BRONZE GRAPHITE BUSHING | 1830 | 18×24×30 |

| BRONZE GRAPHITE BUSHING | 1012 | 10×14×12 | BRONZE GRAPHITE BUSHING | 2010 | 20×28×10 |

| BRONZE GRAPHITE BUSHING | 1015 | 10×14×15 | BRONZE GRAPHITE BUSHING | 2012 | 20×28×12 |

| BRONZE GRAPHITE BUSHING | 1020 | 10×14×20 | BRONZE GRAPHITE BUSHING | 2016 | 20×28×16 |

| BRONZE GRAPHITE BUSHING | 1208 | 12×18×8 | BRONZE GRAPHITE BUSHING | 2019 | 20×28×19 |

| BRONZE GRAPHITE BUSHING | 1210 | 12×18×10 | BRONZE GRAPHITE BUSHING | 2020 | 20×28×20 |

| BRONZE GRAPHITE BUSHING | 1212 | 12×18×12 | BRONZE GRAPHITE BUSHING | 2025 | 20×28×25 |

| BRONZE GRAPHITE BUSHING | 1215 | 12×18×15 | BRONZE GRAPHITE BUSHING | 2030 | 20×28×30 |

| BRONZE GRAPHITE BUSHING | 1216 | 12×18×16 | BRONZE GRAPHITE BUSHING | 2035 | 20×28×35 |

| BRONZE GRAPHITE BUSHING | 1219 | 12×18×19 | BRONZE GRAPHITE BUSHING | 2040 | 20×28×40 |

| BRONZE GRAPHITE BUSHING | 1220 | 12×18×20 | BRONZE GRAPHITE BUSHING | 2050 | 20×28×50 |

| BRONZE GRAPHITE BUSHING | 1225 | 12×18×25 | BRONZE GRAPHITE BUSHING | 2512 | 25×33×12 |

| BRONZE GRAPHITE BUSHING | 1230 | 12×18×30 | BRONZE GRAPHITE BUSHING | 2516 | 25×33×16 |

| BRONZE GRAPHITE BUSHING | 1310 | 13×19×10 | BRONZE GRAPHITE BUSHING | 2520 | 25×33×20 |

| BRONZE GRAPHITE BUSHING | 1312 | 13×19×12 | BRONZE GRAPHITE BUSHING | 2525 | 25×33×25 |

| BRONZE GRAPHITE BUSHING | 1315 | 13×19×15 | BRONZE GRAPHITE BUSHING | 2530 | 25×33×30 |

| BRONZE GRAPHITE BUSHING | 1320 | 13×19×20 | BRONZE GRAPHITE BUSHING | 2535 | 25×33×35 |

| BRONZE GRAPHITE BUSHING | 1410 | 14×20×10 | BRONZE GRAPHITE BUSHING | 2540 | 25×33×40 |

![]()

-

Specifications:

| Material | Bronze | CuZn25Al6Fe3Mn3 + Graphite |

| Iron | Cast-iron + Graphite | |

| Density | 8.2g/cm3 | |

| Tensile Strength | >=755N/mm2 | |

| Anti-compact Tenacity | >=400~500KJ/m3 | |

| Hardness | >=200HB | |

| Max Load Pressure | 100N/mm2 | |

| Speed Limit | 0.5m/s | |

| PV value limit | 1.65N/mm2.m/s | |

| Friction coef | Oil Lubrication | 0.03 |

| Dry Friction | 0.16 | |

| Working temperature | -40~+300°C |