-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Wear Resisting Sliding Bearing Self Lubricating Plain Bearing For Food Canning Machine

| Place of Origin | Self Lubricating Bearings Manufacturers |

|---|---|

| Brand Name | REPLACE BRAND GARLOCK BEARINGS (GGB) |

| Certification | DIN 1494, ISO 3547 STANDARD BUSHING |

| Model Number | BUSHING TYPE FLANGED PLAIN SLEEVE |

| Minimum Order Quantity | NEGOTIABLE |

| Price | Competitively Priced vs DU DX, Provides Lubricating Bush |

| Packaging Details | WOOD PALLET ,WOODEN CASES,CARTON,BUSHINGS EXPORT STANDARD, CUSTOMER SPECIFIED REQUIREMENTS |

| Delivery Time | 7-20 DAYS,STOCK SIZE BUSHING IMMEDIATE DELIVERY |

| Payment Terms | TT IN ADVANCE WESTERN UNION |

| Supply Ability | Flanged Bronze Bushings, Bronze Thrust Washers, Self Lubricating Bronze Bushings |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

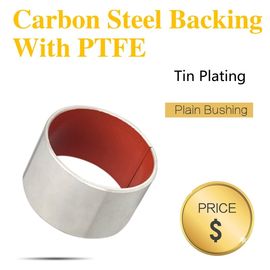

x| Features | Dry, Harden, Wear, Low Friction, Low Resistance | Material | Steel + Bronze Powder + PTFE/Fibre |

|---|---|---|---|

| Type | Sliding Bearing | Application | Food Processor Bushing,Food Canning Machine,Occasions Where Refueling Is Not Possible Or Permitted; |

| Performance Advantages | Simplify Oil Supply Design, Reduce Maintenance And Repair Costs And Time; | Advantages | Good Wear Resistance, Low Friction Coefficient, Extend The Service Life Of The Product |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | PTFE Coated Self Lubricating Plain Bearing, Teflon Self Lubricating Plain Bearing, Steel Backed Self Lubricating Plain Bearing | Characteristic | Втулки скольжения (биметаллические подшипники скольжения) |

| Dry Slide Bearing | Self Lubricating Plain Bearing Work In High Temp & Submerged Applications Where Grease, Oil & Plastics Fail. Reduced Costs & Downtime. Non-galling. Increased Reliability. Run Dry & Keeps Running. | Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ |

| High Light | sintered self lubricating bushes,self lubricating bronze bushings |

||

Wear-resisting & Corrosion resistance | Sliding bearings for Food filling machine Lead-free metal polymer bearings

Food filling machinery requirements of all sliding bearings not only Wear-resisting and Neat, long-term resistance to disinfectant cleaning fluid;Ensure long wear life.

Equipment in the food processing industry must conform to strict hygiene standards

So the bearing must be resistant to corrosion, chemical erosion, and often with water and clean solvent cleaning.

Food processor bushing

Sliding Bearing solution for food processing industry

The sliding bearing is used in the lifting mechanism of the filling machine to ensure long-term wear-resisting and noiseless operation. Because the linear bearing is designed without ball, it has good protection performance against the shaft and runs smoothly, and can resist the scour and corrosion of disinfectant hydrogen peroxide.

Engineering sliding bearing is used in the beverage filling machine to ensure that each clamping mechanism can be 100 percent flexible clamping and release the bottle, and in order to ensure long-term wear resistance but also can resist the hydrogen peroxide disinfectant scour;

The sliding bearing is used in the beverage filling and sealing machine to realize maintenance-free and anti-hydrogen peroxide solution cleaning;

Tech. Data

|

Max. load |

Static |

250N/mm2 |

Max.speed |

Dry running |

0.08~0.20 |

|

|

Very low speed |

140N/mm2 |

Hydrodynamicoperation |

0.02~0.08 |

|||

|

Rotatingoscillating |

60N/mm2 |

Frictioncoefficient |

Dry |

2m/s |

||

|

Hydrodynamic |

>2m/s |

|||||

|

Max. PVdryrunning) |

Short-termoperation |

3.6N/mm2*m/3 |

Thermal conductivity |

42W(m*K)-1 |

||

|

Continuousoperation |

1.8N/mm2*m/3 |

|||||

|

PV max. hydrodynamic |

-195℃~+280℃ |

Coefficient of thermalexpansion |

11*10-6*K-1 |

|||

It can be used in milk filling production line.Allow the cleaning and disinfection of hydrogen peroxide disinfectant;

VSB-40

Steel + Bronze Powder + PTFE/Fibre

Structure

1. PTFE/Polymer fibres mixture thickness 0.01~0.03mm. Lead-free bearing layer provides an excellent initial transfer film, which effectively coats the mating surfaces of the bearing assembly, forming an oxide type solid lubricant film.

2. Sintered bronze powder thickness 0.20-0.35mm, provides max. thermal conductivity away from the bearing surface, also serves as a reservoir for the PTFE mixture.

3. Steel backing, provides high load carrying capacity, excellent heat dissipation.

4. Copper/Tin plating thickness 0.002mm, provides good corrosion resistance.

Features

Suitable for dry running, low coefficient of friction, lower wear, good sliding characteristics, the transfer film created can protect the mating metal surfaces, suitable for rotating and oscillating movement, high chemical resistance, low absorption of water and swelling. The VSB-40 improved the friction and much good wear resistance over the common CSB-10 range under lubricated operation.

Typical Applications

VSB-40 is developed for high duty, oil lubricated, hydraulic applications...Automotivesuspensionstruts,absorbers guide bushing, hydraulic cylinders, gear pumps, motors, axial and radial piston pumps & motors. VSB-40 is designed mainly for using under lubricated conditions and it performs excellent wear resistance and low static/dynamic shockfriction coefficient.

In recent years, the Nigerian government strongly supports the development of food processing industry, so that the related food packaging industry of self-lubricating bearings has been developed rapidly.Nigeria has huge potential demand for sliding bearings for food packaging machinery.Nigeria's flexible packaging market is the second largest in Africa after South Africa, with sales of $245 million, according to the latest figures.In the future, with the growth of Nigeria's middle class population and the improvement and popularization of the retail market, Nigeria's food packaging industry has a huge space for development.

The sliding bearing is 2 in The lifting mechanism of The filling machine to ensure long - term wear - resisting and noiseless operation. Because The linear bearing is designed without The ball,It has good protection performance against the shaft and runs smoothly, and can resist the scour and corrosion of disinfectant hydrogen peroxide.

Engineering sliding bearing is used in the beverage filling machine to ensure that each clamping mechanism can be 100 percent flexible clamping and release the bottle.And in order to ensure long-term wear resistance but also can resist the hydrogen peroxide disinfectant scour;

![]()