All Products

-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

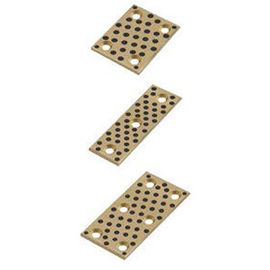

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Contact Person :

Tiffany

Phone Number :

+86 18258386757

Whatsapp :

+8618258386757

High Load Graphite Bronze Wear Plates Cast Bronze Plate C86300 | Oiless Wear Plate Cam units Dayton Moeller Punch

| Place of Origin | Self Lube Bearings |

|---|---|

| Brand Name | bronzelube.com |

| Certification | Plain Sleeve Bearings Standards met: RoHS |

| Model Number | Straight Bushing:Bronze with Embedded Solid Lubricant Material,Lead Free |

| Minimum Order Quantity | Bronze Precision Wear Plates & Lubricating Parts made to order |

| Price | US$0.11 - US$21.11 / Pieces,NEGOTIABLE |

| Packaging Details | Cartons with good information lable |

| Delivery Time | Shipped in 3-20 work days |

| Payment Terms | TT IN ADVANCE,L/C,Western Union |

| Supply Ability | Self Lube Bearing Manufacturing Dimensions Tolerance Assembly |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

xProduct Details

| Material | Aluminum-Bronze With Solid Lubricant | Types | Silde Block |

|---|---|---|---|

| Description | Solid Lubricating Bearings | Application | Mediate Load But Higher Temperature And Condition With Mediate Running Velocity Etc. |

| Size | Standard,Drawings | Shape | Plate |

| Production Feature | Casting | Item | Lamina Wear Plates |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Manufactures Wear Plates Industry Standards (VDI, JIS, NAAMS, SMC). Our Wear Plates Come In A Broad Range Of Standard Inch And Metric Wear Plate | High Light | Bronze Wear Plates , Self Lubricating - Special Brass Alloy |

| Self Lubricating Graphite Plugged Bronze Plate | Bronze Wear Plate And Pad For Industrial Machinery, Manufacturer Of Bronze Sleeve Bushings, We Often Receive Requests For A Variety Of Product Types. | Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ |

| High Light | bronze wear plate,brass wear plate |

||

Product Description

Bronze Wear Plate, Bushings & Bearings Sleeve, Flange, Thrust made to order from china online tiffany@viiplus.com

INDIVIDUAL ORDERS WE DESIGN AND MANUFACTURE SLEEVE BUSHINGS DEPENDING ON THE REQUIREMENTS OF OUR CLIENTS. WE DESIGN THE INCH SIZES BUSHES THE HIGHEST QUALITY STANDARDS.OUR GRAPHITE BUSHING SOLID LUBRICATION BEARINGS ARE MADE OF HIGH STRENGTH BRASS OF SPECIAL FORMULA AS MATRIX, AND HAVE HIGH MECHANICAL PROPERTIES, GOOD CASTING PERFORMANCE AND GOOD CORROSION RESISTANCE.PRODUCTS ARE WIDELY USED IN CONTINUOUS CASTING MACHINES, MINING MACHINERY, SHIPS, GAS TURBINES AND SO ON.

Oiless Wear Plate (500 JPGPB series)

Bronze Wear Plates Graphite Cast Bronze Bearing Solid Bronze Plate C86300 | VSB-50P

Application field

Product application field

Widely used in hydraulic pneumatic, forging machine tool industry, plastics machinery, lifting transportation machinery, port machinery, office, gym machinery, textile machinery, food packages, filling machinery, chemical machinery, printing and packaging, paper making machinery, automobile, railway vehicle, shipbuilding industry, machinery, metallurgical machinery, engineering machinery, etc.

Standard Part Available

SPB, SPF, SPFG, SPW, SGF, SGB, SWP, SLP, SLC, SLI, JEGB, JNA, JESW, JSPW, HGB250, JCBS, JCBSP, JDBS

OILES #500 Wear Plate

Material Structure:

1. Solid lubricant film

2. Solid lubricant plug

3. Bronze backing

Material features

1. Allows maintenance-free and long-life operation

2. Suitable for high static and dynamic loads

3. With low and smoothly coefficient of friction and without stick-slip effects

4. Suitable for dirty, corrosion, impact load and edge loading

5. The base material provided a good shock-absorbing capacity

6. Can be used over a large temperature range

7. Suitable for reciprocating, rotating and oscillating movement with start frequency and difficulty to form oil film occasions

8. With low wear rate and long life service

Allows maintenance-free and long-life operation

Introduction

Oiles #500 bronze materials consist of highly wear-resistance copper cast alloy whose sliding surfaces are evenly provided with a certain percentage of solid lubricant plugs according to work condition, high-strength copper alloy provides a high load-bearing capacity and the solid lubricant can be formation of low friction film. Under technical dry running conditions, the bearing surface is designed with thick running-in film which enables the solid lubricant to be transferred to the counter material at the first contact.

When the mutual friction occurs between two non-lubricated surfaces, the two contacts with the uneven surface of the peak by the shear, stick-slip and plastic deformation giving rise to friction and wear. Conventional lubricants can significantly reduce these effects, however, the conventional lubricant will be more and more squeezed out of the contact area with increasing surface which formed the dry friction or boundary lubrication, With OILES 500 material, the lubrication is effected by the sliding material itself, The solid lubricant is released from the friction material by micro-movement. This gives the sliding partners smooth surfaces with a firmly adhesive solid lubricant film, the solid lubricant film remains within the contact area even under heavy loads. The embedded solid lubricant plugs can be continuously provided to the friction surface to reduce friction resistance and wear, thus make the bearing can be worked under low wear rate and long-life service.

we viiplus bronze bearings offers various types of bronze wear plates, ranging from unfinished cast bronze plate to fully finished machined components. Below are descriptions of the various types we offer.Wear Plates guide and control linear motion when there are heavy forces to contend with. These plates act as linear bearings to guide and control movement.

CHARACTERISTICS

VSB-50P Sliding Block olid Bronze Metallic Self-lubricating Bearings

Solid Lubricant Cast Bronze Bearings Silde Block With Immediate Running Velocity

Metric Bronze Bushings Block Tin-Bronze For Metallurgy / Drying Machine

Cast Bronze Bearing with Graphite Plugs

VSB-50P Sliding Block

Copper Cast Bronze Bearings Slide Block Anti Abrasion For Transportation Machines

1. May work without any ol for long period

2. Extremely high load capacity, good anti-wear and lower friction

3. Particularly appropriate for low speed and high load

4. Suitable for reciprocating, oscillation or intermittent motion where oil film is hard to be formed

5. Good chemical resistant and anti-corrosion characteristics

6. Can b€ used in wide range of temperature from -40℃-+300℃

Aluminum-Bronze With Solid Lubricant Casting Bronze Silde Block

Aluminum-Bronze Solid Lubricating Silde Block is backed with Aluminum-Bronze alloy with good capability of mechanics, castings and anti-erosion. The surface of Aluminum-Bronze Solid Lubricating Silde Block is regularly and finely machined with sockets in which particular solid lubricant is filled.

Aluminum-Bronze Solid Lubricating Silde Block is widely used conditions with mediate load but higher temperature and condition with mediate running velocity etc.

The surface of Aluminum-Bronze Solid Lubricating Silde Block is regularly and finely machined with sockets in which particular solid lubricant is filled.

STRUSTURE

VSB-50P Sliding Block material is made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/low temperature with low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent of oscillating motion.

TECHNICAL DATA

Grade |

50# |

50S1 |

50S2 |

50S3 |

650S5 |

Material |

CuZn25AI5Mn4Fe3 |

CuSn5Pb5Zn5 |

CuAI10Ni5Fe5 |

CuSn12 |

CuZn25AI5Mn4Fe3 |

Density |

8 |

8.9 |

7.8 |

8.9 |

8 |

Hardness |

≥210 |

≥70 |

≥150 |

≥75 |

≥235 |

Tensile strength |

≥750 |

≥250 |

≥500 |

≥270 |

≥800 |

Yield strength |

≥450 |

≥90 |

≥260 |

≥150 |

≥450 |

Elongation |

≥12 |

≥13 |

≥10 |

≥5 |

≥8 |

Coefficient o linear expansion |

1.9×10-5/℃ |

1.8×10-5/℃ |

1.6×10-5/℃ |

1.8×10-5/℃ |

1.9×10-5/℃ |

Max.Temp. |

-40~+300℃ |

-40~+400℃ |

-40~+400℃ |

-40~+400℃ |

-40~+300℃ |

Max.dynamic load |

100 |

60 |

50 |

70 |

120 |

Max.speed(Dry) |

15 |

10 |

20 |

10 |

15 |

N/mm²*m/s(Lubrication) |

200 |

60 |

60 |

80 |

200 |

Compression deformation |

< 0.01 mm |

< 0.05mm |

< 0.04mm |

< 0.05mm |

< 0.005mm |

Chemical Compositions

Product NO. |

Chemical Compositions |

||||||||

VSB-50 |

Cu |

Zn |

Al |

Fe |

Mn |

Si |

Ni |

Sn |

Pb |

60~66 |

22~28 |

5.0~8.0 |

2.0~4.0 |

2.5~5.0 |

<0.1 |

<0.5 |

<0.2 |

<0.2 |

|

AVAILABILITY

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plate

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designs

TYPICAL APPLICATIONS

This kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection molding machines...

![]()

START YOUR

PROJECTWITH AN APPLICATION ENGINEER

thrust washer&plate inch size

Recommended Products