-

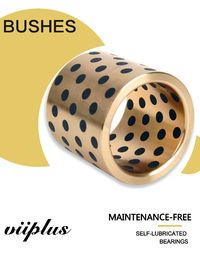

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Continuous Cast Bronze Plugged Bushing , Centrifugal Castings C86300 SAE 430B Manganese Bronze Double loop groove

| Place of Origin | Graphite Bearings Manufacturers |

|---|---|

| Brand Name | SANKYO,MISUMI,DAIDO,SELF LUBE,GGB,FIBRO STANDARD REPLACEMENT BEARING |

| Certification | DIN 1850/ISO 4379, UNITED STATES UNS STANDARD,C86300 |

| Model Number | solid bushing, bronze with lubricant plugs embedded Maintenance-free |

| Minimum Order Quantity | NEGOTIABLE |

| Price | Price Graphite Bushing Parts, (SAE 660) Leaded Tin Bronze Bearings,863 (SAE 430B) 862 (SAE 430A)Manganese Bronze |

| Packaging Details | BUSHING EXPORT CARTONS,WOODEN CASE, SPECIFY REQUIREMENTS |

| Delivery Time | FAST DELIVERY |

| Payment Terms | TT IN ADVANCE |

| Supply Ability | Bronze Bushings Online • Sliding Bearings Manufacturers • Self-lubricating Bushing Suppliers |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum-Bronze With Solid Lubricant,CuSn5Pb5Zn5 | Model Number | Cylinder Bearings,Cylinder Bearings With Flange |

|---|---|---|---|

| Feature | Self Lubrication | Lubrication | Graphite |

| Application | Injection Molding Of Plastics, Pressure Diecast Home > Application Fields > Injection Molding Of Plastics, Pressure Diecast | Bearing Bushing Factory Price | Tiffany@viiplus.com |

| Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ | Item | Bronze Grafitado |

| Graphite Plugged Bushings | Purchase Oilless Bush #500 Spherical Bearing (SPS) From China, Factory Automation & Metal Molding Parts, Industrial Tools And Consumables. | Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ |

| High Light | graphite impregnated bushings,graphite filled bronze bushes |

||

Graphite Plugged Bushings

Viiplus International Made In China specializes in continuous cast bronze bearings, centrifugal castings Bushings,http://www.bronzesleeve.com

Bronze, Brass, Copper Bushing Stock Online.Made to order SLIDING BRONZE Oil Grooves BEARINGS.Power transmission, fluid transport, aerospace, drilling and shipbuilding along with the general manufacturing sector have profited from the reliability and economy of our plain bearings.

C86300 (SAE 430B/ALLOY 424) Manganese Bronze Bushing is a high strength, non-heat treatable alloy intended for use in applications requiring a good combination of outstanding wear characteristics and high bearing strength. C86300 SAE 430B manganese bronze bearing is recommended for low speed, extreme load applications. Conforms to continuous cast specification ASTM B 505Bar Stock & Machine Bushings Parts.Cast Bronze Bushings Solid Bronze Metallic Self-lubricating Bearings Cast Bronze Bearing with Graphite PlugsMaterial:CuZn25Al6Fe3Mn

![]()

Cast Bronze Bushings Double loop groove & double figure eight groove recommended for grease only.

Graphite bronze parts should be run dry with no oil or grease.

Our graphite plug bearings typically have a Working temperature -40~+400°C, Hardness>=210HB depending on a variety of factors affecting performance.Grease grooves are typically wider and deeper than oil grooves. This is to hold a supply of grease and to provide for the thick grease to be forced in. Oil grooves typically vary in width but are shallower than grease grooves. Most oil grooves are operating in a constant loss or closed oiling system that continually feeds the less viscous oil to the grooves.

Maintenance-Free bronze bearings with Oil holes and Plugged graphite are available. The graphite acts as a dry lubricant and provides maintenance-free continuous lubrication. The ID groove patterns can be filled with a special hardenable graphite paste. Graphite Plugs can be press fit through the wall of the bearing with a special epoxy resin binder.

Availability

Bronze Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designs

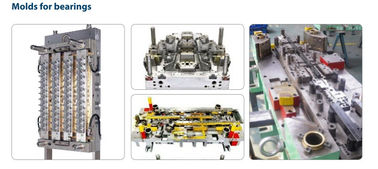

Special copper sleeve bearing for mold

Solid Lubricant Casting Aluminum Bronze Bearings Bushings

Characteristics

VSB-50 Solid lubricating bearings

1. May work without any ol for long period

2. Extremely high load capacity, good anti-wear and lower friction

3. Particularly appropriate for low speed and high load

4. Suitable for reciprocating, oscillation or intermittent motion where oil film is hard to be formed

5. Good chemical resistant and anti-corrosion characteristics

6. Can b€ used in wide range of temperature from -40℃-+300℃

Strusture

VSB-50 material is made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/low temperature with low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent of oscillating motion.

Technical Data

|

Performance |

Data |

|

|

emp. Limits |

|

-40~+400℃ |

|

Max. Dynamic Load |

|

50N/mm² |

|

Max.speed V |

|

20m/min |

|

Max.PV |

|

60N/mm²*m/min |

|

Besides the standard products displayed in the list of this catalogue, we can also supply non-standard products or develop according to customer design. |

||

Typical Applications

This kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection molding machines...

China Bearing Technologies

Customer Bronze Sliding Bearings Size

graphite bronze bushing bronze graphite bushing flange bronze bushing with graphite graphite impregnated bronze bushing graphite bronze bushing bearing graphite coated bronze bushing cast bronze graphite bushing bronze bushing graphite graphite filled bronze bushing oilless bronze graphite bushing graphite sae 841 bronze bushing bronze bushing graphite bushing high quality sintered bronze graphite bushing ptfe graphite bronze bushing carbon impregnated bronze bushing graphite impregnated bronze bushings graphite oilite bronze bushing oilless graphite bronze bushing bronze graphite hole bushing copper graphite bushing oil impregnated sintered bronze bushing graphite impregnated bronze flanged bronze bushing graphite bearing bushing bronze bushing thin wall bearing bronze bushing 10mm manganese bronze bushing self lubricating bronze bushing spherical bronze bushing wrapped bronze bushing oilless bronze bushing cast graphite bushing flange bronze bushing graphite bush bearing bushing with graphite electric motor bronze bushing sintered bronze bushing graphite plug bushing graphite plugged cast bronze bush customized bronze bushing graphite bushing price bronze iron bushing aluminum bronze bushing pb bronze bushing solid bearing bronze bushing graphite brass bushing porous bronze bushing bronze ptfe bushing jdb self lubricating bronze bushing high speed bronze bushing bronze graphite bush cast bronze bushing graphite bronze bush jdb oilite graphite bushing graphite bronze bushings solid bearing bushing graphite guide bushing bronze graphite bronze graphite metal wear plate pads bushing flanged cast bronze bushing metric bronze bushing oiled bronze bushing oil impregnated bronze bushing standard oilless bronze bushing graphite filled bushing misumi bronze graphite guide bushing sintered bronze spherical bushing oil bronze fan bushing carbon graphite bushing bearing graphite copper bushing self lubricating bronze bushing cast bronze bushings bush with graphite embedded bronze bushing brass bronze bushes oil hole bronze bushing graphite bushing for pump graphite lubricating bushing carbon graphite bushing bronze sliding bushing bimetal bushing with graphite sintered bronze graphite injection molding machine bronze bushing bearing self lubricating graphite bushing bronze graphite bushings bronze graphite bearing graphite insert solide bronze bush graphite embedded bushing jcb bronze bushing casting brass and graphite bush oilite graphite bushing graphite insert aluminium bronze bearing bronze bushing bearing bronze bush with graphite insert bronze bushing insert

START YOUR PROJECT WITH AN APPLICATION ENGINEER

Brass: H62, HAl66-6-3-2, an ordinary high-strength brass, special hard high-strength brass (HB> 250), etc. Aluminum Bronze: QAl10-5-5, ZCuAl10Fe3, ZCuAl9Fe4Ni4Mn2, CuAl10Ni etc. Bronze: ZCu5Pb5Zn5, CuSn7Zn4Pb7, CuSn8, CuSn12, ZCuSn10P1 etc. High lead and copper: ZCuPb10Sn10, CuPb15Sn7 etc. Meanwhile according to different customer requirements, in accordance with DIN, BS, EN, UNS, SAE and Chinese GB standards of production of various products (eg: CuZn39Pb3, CuZn40Al2, C86200, C95800, C48200). Welcome to inquire!