-

Oilless Bushes

-

Wrapped Bronze Bearings

-

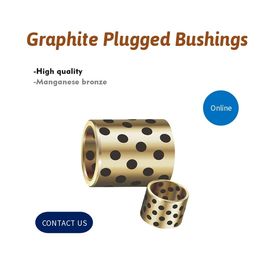

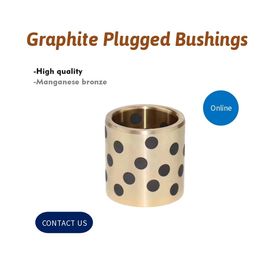

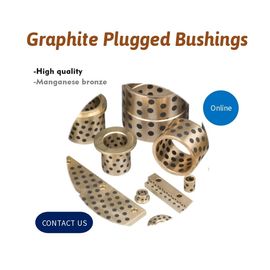

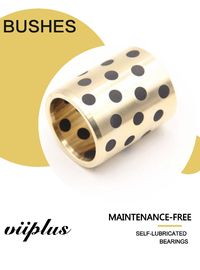

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

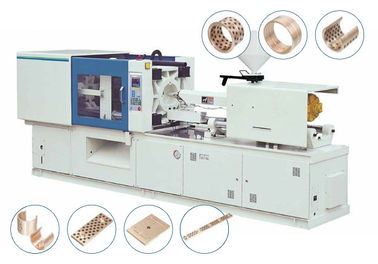

Manganese Bronze Bushing Packaging Machinery Graphite Plugged Bushings Replacement Parts For Plastic Injection Machinery

| Place of Origin | Graphite Bearings Manufacturers |

|---|---|

| Brand Name | SANKYO,MISUMI,DAIDO,SELF LUBE,GGB,FIBRO STANDARD REPLACEMENT BEARING |

| Certification | DIN 1850/ISO 4379, UNITED STATES UNS STANDARD,C86300 |

| Minimum Order Quantity | NEGOTIABLE |

| Price | Price Graphite Bushing Parts, (SAE 660) Leaded Tin Bronze Bearings,863 (SAE 430B) 862 (SAE 430A)Manganese Bronze |

| Packaging Details | BUSHING EXPORT CARTONS,WOODEN CASE, SPECIFY REQUIREMENTS |

| Delivery Time | FAST DELIVERY |

| Payment Terms | TT IN ADVANCE |

| Supply Ability | Bronze Bushings Online • Sliding Bearings Manufacturers • Self-lubricating Bushing Suppliers |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | Cylinder Bearings,Cylinder Bearings With Flange | Material | Manganese Bronze |

|---|---|---|---|

| Feature | Self Lubrication | Lubrication | Graphite |

| Application | Injection Molding Of Plastics, Pressure Diecast Home > Application Fields > Injection Molding Of Plastics, Pressure Diecast | Type | Oilless Metal Sliding Materials |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| Item | Bronze Grafitado | Graphite Plugged Bushings | Purchase Oilless Bush #500 Spherical Bearing (SPS) From China, Factory Automation & Metal Molding Parts, Industrial Tools And Consumables. |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | graphite impregnated bushings,graphite filled bronze bushes |

||

When it comes to packaging machinery and plastic injection machinery, reliable and long-lasting bushings are crucial for ensuring smooth and efficient operations. Our manganese bronze bushings, specifically designed for these applications, offer a robust and durable solution.

Crafted from high-quality manganese bronze, these bushings exhibit excellent wear resistance, corrosion resistance, and mechanical strength. The incorporation of graphite plugs within the bushings provides efficient lubrication, reducing friction and heat generation, thus extending their service life.

Our manganese bronze bushings are precision-machined to fit perfectly into packaging and plastic injection machinery. Whether you need bushings for rotating shafts, pivot points, or other critical components, we have the right parts to meet your needs.

As a leading supplier of graphite plugged bushings, we understand the importance of having reliable replacement parts on hand. That's why we offer a comprehensive range of manganese bronze bushings in various sizes and configurations to suit different machinery models.

Our commitment to quality and reliability is unwavering. We adhere to strict manufacturing standards and employ rigorous quality control measures to ensure that each bushing meets the highest performance standards.

If you're looking for a dependable and durable solution for your packaging or plastic injection machinery, our manganese bronze bushings are the perfect choice. Contact us today to learn more about how our graphite plugged bushings can enhance the performance and efficiency of your equipment.

PROFESSIONAL ALL TYPE OF BRONZE BUSHINGS SUPPLIER.TRUSTED PLAIN BEARINGS MATERIAL COMPANY,COMPETITIVE PRICING & DELIVERY.C86300,C93200...SPECIALTIES: MANGANESE BRONZE,TIN BRONZE, ALUMINUM BRONZE BEARING MATERIAL.

In Sliding Bearing & Bushings, VIIPLUS self-lubricating bearings are optional, low noise and self-lubricating. They are widely used in packing machines, cylinders and automatic guides.

SOLID BRONZE PACKAGING MACHINERY BUSHES METALLIC PLUG GRAPHITE CAST BRONZE LUBRICATION BEARINGS | VSB-50S2

Cast Bronze Bearing with Graphite Plugs

For injection molded housings and application- appropriate, self-lubricating bearings

VIIPLUS China Bronze Metal maintenance-free, self-lubricating bearings exhibit wear- and seizure-resistance in continuous operation of high precision industrial equipment such as machine tools, injection molding machines and robotics.

WE MANUFACTURE AND DESIGN BRONZE BUSHINGS FOR DIES & MOULD.WORKING TOGETHER TO CREATE SOLUTIONS FOR THE MOST DEMANDING PLAIN BEARING APPLICATIONS.STANDARD-STOCKED SIZE FOR BRONZE BUSHINGS.WE ARE CASTING BRONZE WITH DIFFERENT MATERIAL ACCORDING TO CUSTOMER REQUIREMENT. WE CAN OFFER THE COMMON MATERIAL IN PHOSPHORUS BRONZE(C51000,C52100,C52400,C53400,C54400), LEADED TIN BRONZE{C93200(SAE660,RG7),C93600,C93700(SAE64),C93800(SAE67),C94100}, ALUMINIUM BRONZE(C61000,C61300,C62300,C62400,C62500,C63400,C95400)

MANGANESE BRONZE(C67300,C67400,C86200(SAE430A),C86300(SAE430B),C86500),

TIN BRONZE(C90500(SAE62),C90700(SAE65),C91000,C92300,C92700)

AND NICKEL ALUMINUM BRONZE(C9500,C95800,CUAL10NI5FE5). WE MANUFACTURE AS PER BS (BRITISH STANDARD), ASTM (AMERICAN STANDARD), DIN (GERMAN STANDARD), JIS (JAPANESE STANDARD) OR ANY OTHER STANDARD DESIRED BY THE CUSTOMER.

Graphite is mechanically forced into the holes/grooves under extreme pressure. A film of lubricant is transferred to the shaft as it begins to turn. These bearings offer continuous lubrication over long periods without maintenance.Plug graphite bearings are primarily used in applications that need continual lubrication in hard to reach areas.

Widely used in the injection molding machine molding machinery, rubber machinery, die-casting machines and other occasions.

Bearing Advantages:when using the solid lubricant bushing ..

There is no needs for considering the oil-putting set in designOil offering system is an energy waste and time waste set in mechanical design.

Properly and simply designed, widely used;

![]()

FEATURE

The high strength copper alloy provides the mechanical bearing capacity of the bearing, and the lubricant can provide a continuous source of lubrication for the bearing surface to form a good friction pair. Suitable for medium and high load, frequent failure to refuel or difficult formation of oil film. Typical applications include: plastic mechanical elbow bearing, green pillar guide sleeve, port machinery, hydraulic engineering gate, mining equipment, etc.

PRODUCT ADVANTAGES

·Can be used for a long time without maintenance;

·Designed for high static load and dynamic load;

·Low friction coefficient, no "sticking" phenomenon;

·Dust resistance, corrosion resistance, impact resistance and edge load resistance;

·The metal substrate has good shock absorption ability;

·Can be used in a wide range of temperature;

·Suitable for reciprocating, rotating and swinging start frequent and difficult to form oil film occasions;

Special bronze bearing for injection molding machine

Injection Molding of Plastics, Pressure Diecast

The VIIPLUS manufacturer company has been committed to new Graphite Plugged Bushings research and development, material performance, improved JDB series solid inlaid self-lubricating axle sleeve with high strength, wear resistance, free maintenance etc, has successfully supporting several world famous manufacturers of injection molding machine, die-casting machine.

![]()

SELF-LUBRICATING BEARINGS ARE TYPICALLY USED IN THE FOLLOWING APPLICATION

My company's self-lubricating bearing Graphite Plugged Bushings products have been supplied in the chassis walking body, body parts, hydraulic components and other components.

Including bimetal boundary lubrication rolling bearings, metal-based self-lubricating bearings and metal-plastic self-lubricating rolling bearings.

These bearing materials have excellent wear resistance and dust resistance under high load conditions, and the self-lubricating technology greatly prolongs the maintenance cycle of the bearing, thus improving the utilization ratio of the equipment and reducing the maintenance cost.

Material:CuAI10Ni5Fe4

TYPICAL APPLICATION

![]()

The Graphite Plugged Bushings is widely used on consecutive casting and rolling machines, mine-exploiting equipments, ships, steam engine, etc.

Hydraulic Cylinder Casting Bronze Flange Bearing With Solid Lubricant

MATERIAL STRUCTURE

1. Design the initial lubrication film as required to reduce the initial friction factor.

2. Solid lubricant, according to the direction of movement has a regular embedded arrangement, in the course of operation, the release to the bearing surface to form a solid lubrication film, play a role in reducing the friction factor to improve the wear resistance.

3. High strength copper alloy, provides bearing performance of bearing substrate, has better impact resistance, corrosion resistance.

STRUCTRUE CHARACTERISTICS APPLICATIONS

VSB-50 Solid Lubricating Bearing is produced by strengthening brass that has good physical performance and good capability for casting. What's more, the brass material has pretty good anti-erosion abitity in air, fresh water and sea water. The surface is regularly and finely machined with sockets in which particular solid lubricant is filled. The Graphite Plugged Bushings is widely used on consecutive casting and rolling machines, mine-exploiting equipments, ships, steam engine, etc.

Solid Lubricant Casting Aluminum Bronze Bearings Bushings

CHARACTERISTICS

With Solid Graphite Lubrication.

Various material specifications, standard and special shapes are also available.

VSB-50 Solid lubricating bearings

1. May work without any ol for long period

2. Extremely high load capacity, good anti-wear and lower friction

3. Particularly appropriate for low speed and high load

4. Suitable for reciprocating, oscillation or intermittent motion where oil film is hard to be formed

5. Good chemical resistant and anti-corrosion characteristics

6. Can be used in wide range of temperature from -40℃-+300℃

STRUSTURE

VSB-50 material is made of strong cast bronze based metal with special solid lubricants embedded. The base metal withstands high load and the solid lubricants provide self-lubrication. The bearing shows excellent performance without pre-lubrication under conditions of extreme high/low temperature with low speed. This material provides a maintenance-free bearing solution, particularly for high load, intermittent of oscillating motion.

TECHNICAL DATA

|

|

Data |

|

|

Material |

|

CuSn5Pb5Zn5 |

|

Density |

|

7.8g/cm³ |

|

Hardness |

|

>150HB |

|

Tensile strength |

|

>600N/mm² |

|

Yeild strength |

|

>260N/mm² |

|

Elongation |

|

>10 % |

|

Coefficient of linear expansion |

|

1.6·10-5/℃ |

|

Performance |

Data |

|

|

emp. Limits |

|

-40~+400℃ |

|

Max. Dynamic Load |

|

50N/mm² |

|

Max.speed V |

|

20m/min |

|

Max.PV |

|

60N/mm²*m/min |

|

Besides the standard Graphite Plugged Bushings products displayed in the list of this catalogue, we can also supply non-standard Graphite Plugged Bushings products or develop according to customer design. |

||

AVAILABILITY

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Sliding plates

Bearing forms made to order: standard forms in special dimensions, thrust washers, flanged thrust washers, half-bearings, special shapes obtained by stamping or deep drawing, customized bearing designs

TYPICAL APPLICATIONS

This kind of bearing can be applied under dry, high temperature, high pressure, corrosive, water or other chemical environments when no oil can be introduced. It is widely used in automotive Graphite Plugged Bushings products line, water engineering, dam gate, plastic industries, successive casting machines, steel rollers in metallurgy industry, mineral machines, ships, turbo generators, hydraulic turbines and injection molding machines...

China Bearing Technologies

Your recognised global partner for sliding bearing applications.

Working together to create solutions for the most demanding bearing applications.

BUSHINGS CUSTOMER SIZE

START YOUR PROJECTWITH AN APPLICATION ENGINEER

Bushings,Lubricated Bearings,Composite Bearings,Metal Bearings,Compressor Bearings,Metal-polymer,Filament Wound,Plain Bearings,Flange Bearings,Polymer Bearings,Flange Bushings,Pump Bearings,Flanged Bushes,Thrust Plates,Industrial Bearings