-

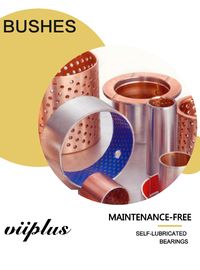

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Engeneering in Motion Dry Sliding Bearing Grease Lubricated POM Bushing

| Place of Origin | MADE-TO-ORDER FROM CHINA |

|---|---|

| Brand Name | REPLACEMENT GARLOCK BEARINGS (GGB) |

| Certification | STANDARD DIN 1494, ISO 3547 BUSHING |

| Model Number | METAL/POLYMER COMPOSITE PLAIN BEARINGS FLANGED PLAIN SLEEVE |

| Minimum Order Quantity | ORDER BUSHING ONLINE,STOCK SIZE NO MOQ QUANTITY |

| Price | NEGOTIABLE,CHEAP PRICES |

| Packaging Details | CARTONS,WOODEN CASE,SPECIFY REQUIREMENTS |

| Delivery Time | 3-20 DAYS |

| Payment Terms | TT IN ADVANCE,L/C,WESTERN UNION |

| Supply Ability | Self-lubricating Dimensions Tolerance • Custom Bushings Assembly • Sliding Bearings Suppliers |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Meterial | Carbon Steel + Copper Powder + Bule POM | Plating | Tin Or Copper |

|---|---|---|---|

| Type | Wrapped Bushes, Thrust Washer | Lubricating | Boundary Lubricating |

| Customized | Based On Drawing Or Sample | Color | Black,red,yellow,blue POM |

| Application | Automotive Chassis, Forging Machines, Mine Quarrying Machines, Metal Melting And Casing Machines And In Water Irrigating And Steel Rolling Industries, Etc. | Bearing Bushing Factory Price | Tiffany@viiplus.com |

| Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ | High Light | Self Lubricating Bronze Bushings, Dry Bearing |

| Dry Slide Bushings Bearing | The Dry Slide Bushings Trademark Identifies A Whole Range Of Self-lubricated Dry Sliding Bushings And Bearings. | Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ |

| High Light | oilite bronze bushings,plain bearing bush |

||

The dry sliding bearings are encapsulated sliding bearings made of a three-layer composite produced from a steel strip.

Self-lubricating bearings Engeneering in Motion.High-quality steel sleeve bushing or stainless steel Food-friendly design Plain Bearings and Sleeve Bearings Metal-Polymer Grease Lubricated POM Bushes | Special sleeve bushings lead free requirements in the Beverage technology General packaging Food industry in high temperatures availabe

ROLLED DRY SLIDING BEARINGS (POM)

Materiai:Carbon Steel + Copper Powder + POM (without lead

Typicai applicaton

It's used in vehicle chassis, forming machine tools, steel metallurgical machinery, mineral mountain machinery, hydraulic industry and rolling steel industry, etc.

Wrapped Acetal Lined (low-maintenance), oil or grease lubricated bearings, carbon steel shell with sintered bronze layer with a co-acetal polymer layer, plain bearings, thrust washer and strip

Steel + Bronze Powder + POM(DX)

Self Lube Bearings Product Category SF-2 Boundary Lubricating Bearing

Characteristics

VSB-20 Boundary lubrication bearing High Quality DX Bushing POM Bush China Manufacturer

· marginally lubricated bushings for grease or oil lubricated applications

· Standard parts contain grease indents in the sliding layer; plain sliding layer available by request

· Optimum performance under relatively high loads and low speeds

· Suitable for linear, oscillating and rotating movements

· Wide range of parts available from stock

Product Range

The products and their competitive pricing

-

Bush Bearing

-

Sintered Bearings

-

Self Lubricated Bush Bearings

-

Sintered Bronze / Iron Sintered Self Lubricated Bushes

-

Dry Bushes & Washers

-

Graphite Filled Bronze Bushes

Suitable for rotating and oscillating movement, less maintenance requirements due to the long re-lubrication intervals, lower wear, lower susceptibility to edge loading, no absorption of water and therefore no swelling, good damping behaviours, good resistance to shock loads.

Strusture

1. POM thickness 0.30~0.50 mm. It provides high wearresistance and low friction even with only minute volume oflubricant are supplied, this bearing surface carries a pattern of circular indents which should be filled with grease on assembly of the bearing.

2. Sintered bronze powder thickness 0.20-0.35mm. A special composition of powdered copper is thermally fused to the steel backing. This contact layer acts as an anchor for the PTFE layer and conducts the thermal build up away from the bearing surfaces.

3. Low-carbon steel.Setting the foundation of the bushings, the steel back provides exceptional stability,load carrying and heat dissipation characteristics.

Technical Data

Structure And Composition

· Metal-Polymer Composite Bushing Material

· Steel Back + Porous Bronze Sinter +

POM with Lubrication Indents

|

|

Sliding layer POM |

![]()

|

OPERATING PERFORMANCE |

|

|

Dry |

Poor |

|

Oil lubricated |

Good |

|

Grease lubricated |

Very Good |

|

Water lubricated |

Poor |

|

Process fluid lubricated |

Poor |

Avaibearing Properties

|

GENERAL |

|

Unit |

Value |

|---|---|---|---|

|

Maximum load, p |

Static |

N/mm2 |

250 |

|

Operating temperature |

Min |

°C |

- 40 |

|

GREASE LUBRICATED |

|

|

|

|

Maximum sliding speed, U |

|

m/s |

>2.0 |

|

|

|

|

|

|

Coefficient of friction |

|

|

0.05 – 0.20 |

|

|

|

|

|

|

|

|

|

|

Technical data

|

Max. load |

Static |

250N/mm2 |

|

Dynamic |

140N/mm2 |

|

|

|

Rotaing oscillating |

60N/mm2 |

|

Max. speed |

Dry |

2m/s |

|

Lubrication |

>2m/s |

|

|

Max. PV (Dry) |

Short-time |

3.6N/mm2*·m/s |

|

Continuous |

1.8N/mm2*·m/s |

|

|

Temp. |

-195℃~+280℃ |

|

|

Friction coefficient Dry |

0.03~0.20 |

|

|

Lubrication |

>2m/s |

|

|

Thermal conductivity |

42W (m·k)-1 |

|

|

Coefficient of thermal expansion |

11*10-6k-1 |

|

Availability

Bearing forms available in standard dimensions

· Cylindrical bushes

· Thrust washers

· Sliding plates

Metric bearings and imperial bushings made to order: standard bushing forms in special dimensions, half-bushings, special shapes obtained by stamping, bearings with locating notches, lubricant holes and machined grooves, customized bushing designs

Typical Applications

Recommended for applications involving intermittent operation or boundary lubrication... Automotive: suspension joints, kingpin assemblies and stub axles of trucks, automobile driving joint hinges, steering and other linkages, articulation joints, rear chassis hinges, fair leader rollers... Machine tool building industry: spindles in drill, grinding, and milling machines, ram guide plates in multi-ram presses... Agricultural equipment: gearbox, clutch, bale trips and wheel caster swivels for bale accumulators, front axle pivot bearings, steering idler box bearings and kingpin bearings for harvesters... It is especially well-suited for applications where lubricant can not be supplied continuously or repeatedly.

STOCK SIZE for Self Lubricating Bearings

START YOUR

PROJECTWITH AN APPLICATION ENGINEER

Plain Bearings & Self-lubricating Bushings | VIIPLUS Surface Engineering|Bearing Technology