-

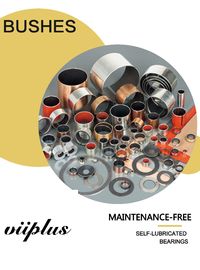

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Gate , Globe , Check Valve Sleeve Steel Shaft Bushes Ball Valve Metal Polymer Composites Plain Bearing

| Place of Origin | Valve Bushing Manufacturer |

|---|---|

| Brand Name | Straight Sleeve Bore Bushings |

| Certification | wrapped bushing, Bronze Steel self-lubricatging bushing, DIN 1494 / ISO 3547, Low-maintenance |

| Model Number | sleeve Bushing Applications include valves, commercial fire sprinkler systems, mixers, blenders, swivels, and extruders. |

| Minimum Order Quantity | 100 Piece/Pieces (Min. Order) |

| Price | Negotiable |

| Packaging Details | Export standard packing |

| Delivery Time | 1~2 WEEKS |

| Payment Terms | TT IN ADVANCE |

| Supply Ability | Valve Split Steel Bushings Shaft Bearings Suppliers |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Meterial | Carton Steel , Bronze , PEEK | Plating | Tin Or Copper |

|---|---|---|---|

| Port | ShangHai | Type | Bushes |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Valve Bushings Suppliers | Self-lubricating, Metal-polymer Plain Bearing | Metal-Polymer Anti-Friction Plain Bearings |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | oil impregnated bushings,teflon sleeve bearing |

||

Gate, globe, and check valves are critical components in various industrial fluid systems, controlling the flow of liquids and gases. The performance and durability of these valves depend heavily on the quality of their internal components, particularly the steel shaft bushes and plain bearings.

Steel shaft bushes play a vital role in guiding and supporting the movement of the valve stem. They must withstand high loads and frequent operation while maintaining a tight seal to prevent leakage. Metal polymer composites are increasingly being used in the manufacture of these bushes due to their exceptional mechanical properties.

These composites offer a unique combination of strength, stiffness, and wear resistance. They can also be tailored to specific application requirements, providing optimized performance in a range of environments. In ball valve plain bearings, metal polymer composites offer superior durability and reduced friction, enhancing the overall performance of the valve.

Our company specializes in the production of gate, globe, and check valve sleeve steel shaft bushes and ball valve plain bearings using metal polymer composites. We employ advanced manufacturing techniques and rigorous quality control procedures to ensure the highest levels of performance and reliability.

Whether you're upgrading an existing system or designing a new one, we can provide the right solution for your valve bush and bearing needs. Contact us today to learn more about our products and how we can help you achieve superior performance in your fluid system applications.

Gate ,Globe ,Check Valve Sleeve Steel Bushes Ball Valve Washer Butterfly Valve Spilt shaft Bushings supplier China Cheap Wholesale Bushing-There are various self-lubricating bearings available for choice. - POLYMER PLAIN BEARINGS Manufacturer for many years.

VSB-30 Metal-Polymer Hydrodynamic Composite Bearings

Steel Bronze Powder with PEEK/PTFE Marginal Bearings, provides maintenance-free operating, Temperature be allowance from -150 until +250°C, operate satisfactorily without lubrication under lieght duty and low speed, high static and dynamic load

Steel + Bronze Powder + PEEK/PTFE

CHARACTERISTICS

VSB-30 Features

1 . VSB-30 provides maintenance-free operation

2 . Operate satisfectorily without lubrication under light duty and low speed

3 . VSB-30 has a high PV capability under high temperature

4 . Temperature allowance is from -150℃-+250℃

5 . Good chemical resistance

6 . High static and dynamic load capacity

7 . No water absorption

8 . Suitable for rotating , oscillating , reciprocating and sliding movement .

STRUSTURE

1.PEEK/PTFE 0.30~0.50mm. It has high wear resistance and low friction even only minute of lubricant are supplied. The bearing surface carries a pattern of circular indents which will be filled with grease on assembly of the bearing.

2.Bronze layer 0.20~0.35mm. A special composition of powdered copper is thermally fused to the steel backing. This contact layer acts as an anchor for the PTFE layer and conducts the thermal build up away from the bearing surfaces.

3.Steel backing.Setting the foundation of the bushings, the steel back provides exceptional stability, load carrying and heat dissipation Characteristics.

TECHNICAL DATA

|

Max. load |

Static |

250N/mm2 |

|

Dynamic |

140N/mm2 |

|

|

|

Rotaing oscillating |

60N/mm2 |

|

Max. speed |

Dry |

5m/s |

|

Lubrication |

>5m/s |

|

|

Max. PV (Dry) |

Short-time |

4.8N/mm2*·m/s |

|

Continuous |

3.6N/mm2*·m/s |

|

|

Temp. |

-150℃~+250℃ |

|

|

Friction coefficient |

0.03~0.20 |

|

|

Thermal conductivity |

50W (m·k)-1 |

|

|

Coefficient of thermal expansion |

11*10-6k-1 |

|

AVAILABILITY

Bearing forms available in standard dimensions

· Cylindrical bushes

· Thrust washers

· Sliding plates

TYPICAL APPLICATIONS

VSB-30 bearings application covers gear pump , ABS system , piston pump , gear motor , machine tools , agricultural machinery and so on . The materials is recommended with initial pre-lubrication at assembly .

SIZE

START YOUR PROJECT WITH AN APPLICATION ENGINEER