-

Oilless Bushes

-

Wrapped Bronze Bearings

-

Graphite Plugged Bushings

-

Bronze Sleeve Bushings

-

Self Lubricating Plain Bearing

-

Bronze Gleitlager

-

Polymer Plain Bearings

-

Bimetal Bearing Bushes

-

Bronze Plain Bearings

-

Plastic Plain Bearings

-

Self Lube Wear Plates

-

Stainless Steel Bushings

-

Cast Bronze Bushings

-

Bronze Bushing Material

-

Valve Bushing

-

Self Lubricating Bronze Bushings

-

Flanged Sleeve Bearing

-

Dry Sliding Bearing

-

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality.

David from CanadaOur company import the bronze gleitlager from viiplus china,viiplus professional team makes sure customs clearance is always smooth. They provide an accurate bronze bushing classification, handle all the paperwork,We have received the self-lubricating bronze bushings. They look well done and the high quality. -

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts

Valerie from CaliforniaWe import the bronze gleitlager from China to under the incoterm FOB shanghai, sometimes by Air. viiplus is a very good bronze gleitlager supplier, they are very professional and patient, after we inform the new order, they will manufacturer bronze gleitlager in time and give us the schedule , and then we just need to receive the bronze parts -

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

Daisy From GermanyThe best surface finishes for Sleeve Bearing, tighter concentricity, and bronze bushings material uniformity. The good supplier of standard inch and metric sleeve bearings and bushings from china. https://www.bronzelube.com/

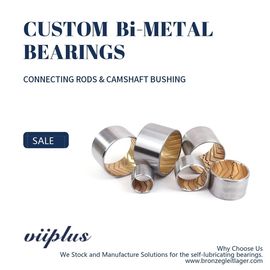

The Online Source For Thermoplastic Pumps Bi-Metal Bearing & Bushings

| Place of Origin | Bimetal Bearing Manufacturers |

|---|---|

| Brand Name | bimetal SAE-797 SAE 48 SAE-799 bushings |

| Certification | Bimetal Bush Material CuPb10Sn10、CuPb6Sn6Zn3 CuPb24Sn4... |

| Model Number | JF800 JF720 JF700 Bimetal Lead-Free Plain Bearings |

| Minimum Order Quantity | 800 Piece/Pieces (Min. Order) |

| Price | $0.20 - $2.00 / Pieces ,Negotiable |

| Packaging Details | export & import bimetal bushings International carton standard |

| Delivery Time | Manufacture Bimetal Bushing In Stock, Delivered Within Days. |

| Payment Terms | TT IN ADVANCE Western Union |

| Supply Ability | casting bimetal bushing, China, manufacturers, suppliers, factory, wholesale, Metric Self Lubricating Bushing, Self Lubricating Bushings, Journal Bronze Bearings, Bimetal With Graphite Bearing, Metallic Bearings, Flanged Bimetallic Plain Bearing |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Meterial | Steel+CuPb10Sn10 Alloy | Plating | Tin Or Copper |

|---|---|---|---|

| Characteristic | Plain Bearings | Type | Bushes, Collar Bushes, Washers, Strips Or Special Designs |

| Size | Standard Size Available | Quality | OEM |

| FEATURES | Normal Cylindrical Bushes, Grooves, Oil Holes, Slots, Etc. | MAJOR APPLICATIONS | Engine Bearings, Automotive Parts, General Industrial Machinery, Food Machinery And Household Electric Appliances |

| Bearing Bushing Factory Price | Tiffany@viiplus.com | Self-lubricating Bearing Bushing Manufacturer | Https://www.viiplus.com/ |

| High Light | Steel Backed Bronze Bushing, Bimetallic Bushes | Bimetallic Bearing Bushing | Bimetal Bearing With Steel Backing And Bronze Overlay • Particularly Suitable For High ... Bimetal Plain Bearings To Standard SAE 792 |

| Bush Bearings Manufacturers Suppliers Exporters | Plain Bearings. Long, Maintenance-free Service, Manufactures Bushings In Various Designs And From Different Materials. Tiffany@viiplus.com, Bushings - Configure And Purchase - Https://www.viiplus.com/ | ||

| High Light | bimetal bush,bimetal bearings |

||

The bronzegleitlager.com offers high-quality genuine spare bronze bushings parts for construction and agricultural machinery. Discover our bronze bushings product range.

Welcome to our online source, your one-stop shop for thermoplastic pumps, bi-metal bearings, and bushings. Here, we offer a comprehensive range of high-quality products that are designed to meet the demands of various industrial applications.

Our thermoplastic pumps are made from durable and reliable materials that ensure efficient and smooth operation. Whether you need pumps for chemical processing, food and beverage handling, or any other industry, we have the perfect solution for you.

Complementing our pump selection, we also provide a wide array of bi-metal bearings and bushings. These precision-engineered components are crafted from a combination of metals that offer superior wear resistance, corrosion protection, and lubrication properties. This unique combination ensures longer lifespan and optimal performance, even under extreme conditions.

At our online store, you can easily browse through our extensive inventory, compare product specifications, and make informed purchase decisions. We also provide convenient online ordering and fast delivery options to ensure that you get the products you need, when you need them.

Moreover, our team of experts is always available to assist you with any questions or concerns you may have. We pride ourselves on providing excellent customer service and ensuring that our customers are fully satisfied with their purchases.

So, whether you're looking for thermoplastic pumps, bi-metal bearings, or bushings, look no further than our online source. We have everything you need to keep your industrial operations running smoothly and efficiently.

We carry a full range of Bimetal (split) Bushings

Material Steel+CuPb10Sn10,Steel+CuPb24Sn4,Steel+CuPb24Sn,Steel+CuPb30 Steel+CuPb10Sn10+Graphite.You can order online for fast and immediate shipping. Please give us a call or send us an e-mail on bushings to help with product selection or to find bushings not listed on our web site.Bushings Catalog (Plain Bearings Catalog) Bimetal Wrapped Steel with Bronze Series Bushings Catalog - Metric [Also available in Flanged type]

BIMETAL BUSHING BEAINGS VSB-800.pdf BIMETAL STEEL BRONZE SLEEVE BUSHES MANUFACTURER.pd...

Manufacturer & Exporter Bimetal, Trimetal and Solid Cast Metal Bearings & Bushings,Bimetal Bearings_SAE 797, SAE 799, SAE 783, SAE 48, SAE 49,Manufacturers of Reference And Material Characteristics Customized bimetal sleeve bushings manufacturing, supplier of bronze steel bushing and self-lubricating bearing,and other self-lubricating bearings. Specializing in plain bearings solutions.www.bronzegleitlager.com is the leading bimetal bearings sourcing and sliding bearing

supplier discovery online website for procurement professionals, engineers, plant & facility management and business...

Steel backed Leaded Bronze:

Standard For Bimetallic Materials

DIN CuPb10Sn, SAE797, UNS C93700, federal Mogul / Talho HF2, Glacler SY,SAE792

CuPb24Sn4, SAE799, DAIDO L23,JIS-LBC6, GLYCO-68, ACL-F250, SAE794

Steel backed Copper-Lead Alloy: CuPb24Sn SAE-49, ACL-F780 CuPb30, SAE-48, JIS-KJ3.

![]()

JF800 Bimetallic Bearing's steel-bronze bushes with oil holes China The source for Pumps bushings & Bimetal Bearing online sale Bimtel Bearing: BM JF600 JF650 JF700 JF720 Description

Bimetallic bushing is formed from steel strips with alloy lining material. The alloy lined surface can be machined oil grooves, holes, formed Indentations etc according to different application. It is suitable for high load, lower speed oscillation & rotation movement.

VIIPLUS china BiMetal bushing Load capability can be improved by oil holes, grooves, etc., depending on lubrication conditions. In some cases, a dry bearing can also be used under lubricated conditions.

Bimetallic bearing is steel back as the matrix, surface sintered copper, tin alloy, rolled rolling bearings, standard alloy materials are: CuPb10Sn10, CuSn6Zn6Pb3, CuPb24Sn4, CuPn30, AlSn20Cu.

Since the base plate is made of low carbon steel, the machining accuracy of the outer diameter of the shaft sleeve is guaranteed. Moreover, there is no need for screw fixation after the product is loaded into the seat hole. Interference fit can be relied on to prevent the appearance of external circle.

The change of the chemical composition of the alloy on the inner surface can meet the requirements of different bearing pressure, different service temperature and different sliding speed. The oil groove with different structure is designed for the friction surface in the production, and the oil cavity can meet the requirements of different ways of oiling and prevent the phenomenon of axle biting.

Metal-Polymer Anti-Friction Plain Bearings

Rolled Dry Sliding Bearings (Ptfe)

Steel + Bronze Powder + CuPb24Sn4 and Or other

CuPb24Sn4 Lined (maintenance-free), self lubricated plain or flanged bearings, thrust washer and strip, Carbon steel shell with sintered bronze layer filled with CuPb24Sn4

Typical Applications

The application of bimetal, must be designed with oil lubrication conditions, suitable for high load and low speed rotation, swing motion.At present, it has been widely used in automobile balance bridge, spring plate seat hole, brake shoes, steering knuckles, motion connecting rod, punch sliding parts, bulldozer support, heavy driving wheel, gear box, oil pump, cylinder, engine, clutch and so on.Also widely used in mining machinery, turbo - car, construction machinery, agricultural machinery, steel rolling machinery and so on.

-

Api Process Pumps Bronze Bushings

-

Bronze Bushings

-

Chemical Process Pumps Bronze Bushings

-

Industrial Process Pumps Bronze Bushings

-

Slurry Pumps Bronze Bushings

-

Solids Handling Pumps Bronze Bushings

Strusture

Carbon Steel + Copper Powder

Availability

Bearing forms available in standard dimensions

· Cylindrical bushes

· Flanged bushes

· Thrust washers

· Flanged washers

· Sliding plates

![]()

Parts are available in standard sizes for a wide range of bearing products with basic dimensions (inner diameter, outer diameter, length, etc.) in accordance with international standards. Special bearings with additional functions can be manufactured according to customer specifications and requirements.

START YOUR PROJECT With an Application Engineer BIMETAL BUSHING

![]()

viiplus products are widely used in all industrial fields

Widely used in hydraulic and pneumatic industries, forging machine tool industry, plastics machinery industry, lifting and handling machinery, port machinery, office, fitness machinery, textile machinery, food packaging, filling machinery, chemical machinery, printing and packaging, paper making machinery, automobiles, railways Steam locomotives, shipbuilding industries, presses, metallurgical machinery, construction machinery, etc.